Production of fiberglass reinforcement as a business. Business in the production of composite reinforcement

In the construction industry, a lot of materials are used, many of which can be made decently. But for a novice entrepreneur who decides to occupy his own niche here, it is better to choose as the material produced, one that does not require huge investments and labor costs. And in this list, without a doubt, fiberglass reinforcement can be attributed. If you buy equipment for the production of composite reinforcement of proper quality, you can supply the market with products that are in demand by both large construction companies and private builders. Fiberglass (composite) reinforcement is a bundle of continuous glass fibers characterized by high strength. The thinnest threads here are connected by means of a special synthetic resin. Products can be used in the field of construction and decoration.

Our business valuation:

Starting investments - from 1300000 rubles.

Market saturation is average.

The complexity of starting a business is 6/10.

But despite the fact that the implementation of the idea does not require significant investment, it is necessary to carefully work out a business plan for the production of composite reinforcement, which will include the following points:

- Market and competition analysis.

- Technology for obtaining material.

- Workshop equipment.

- Financial justification of the project.

How is the production of composite reinforcement?

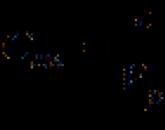

Technological scheme of production

The workshop for the production of composite reinforcement within its walls will process 2 main components:

- Bonding material (special mixture prepared on the basis of epoxy resin).

- Reinforcing material (roving).

In the finished product, the roving takes on all the mechanical load exerted on it, and the binder distributes it along the entire length of the rod.

It is impossible to designate at least any exact ratio of components - a lot depends on the purchased raw materials, temperature and humidity indicators in the workshop, the type and diameter of the manufactured reinforcement. And therefore, the final recipe will either have to be developed independently (if there is specific knowledge), or a specialist should be involved in the work. And the second option here is more optimal, since in the future the technologist will also monitor compliance with all modes in the process of manufacturing reinforcement.

Whatever raw materials are processed in the workshop, its strict incoming control should be organized, since the guarantee of quality finished products– high-quality components from reliable suppliers.

The manufacture of composite reinforcement is a high-tech process that includes many physical and chemical reactions. But since all operations here are carried out with the help of special machines and devices, the technology for the production of composite reinforcement is quite simple:

- Fiberglass is impregnated with resin to form continuous lines.

- The roving is fed to a forming die, the output of which is a rod of a given geometry and characteristics.

- The material is pulled under certain temperature indicators through the polymerization chamber.

- A "ribbing" is created on the rod.

The received products after the final stage are sent to warehouses for storage. Composite rebar can be stored in warehouses for a very long time, which is another advantage of the planned business - you do not have to worry about damage to products.

Technical equipment of the workshop

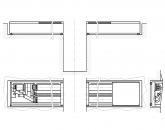

Composite Rebar Production Line

Mini plant for the production of composite reinforcement must be equipped with special automatic equipment. And its choice will depend on the planned sales volumes and available investments. And when choosing, you should not focus only on the cost of machines, it is better to prefer a proven manufacturer that supplies only high-quality machines and devices to the market.

The complete composite rebar production line is equipped with the following machines:

- creel for unwinding threads,

- yarn warmer machine

- soaking bath,

- filter set,

- wrapper,

- polarizing oven with the possibility of cooling products,

- stretching machine,

- rod cutting machine.

It is better for an entrepreneur to buy a line ready for work immediately, and not to equip the workshop with separate machines.

The price of equipment for composite reinforcement will depend on its functionality and power. On average, a good quality line that can produce products of different diameters costs 800,000-1,500,000 rubles. In the absence of such funds, you can think about purchasing used machines or renting them.

Requirements for a production facility

You can find a production facility in the industrial part of the city. Any empty building is suitable here, where water supply, sewerage and electricity can be provided. As for the area of the workshop itself, the machine for the production of medium-sized composite reinforcement can be placed on 50 m 2. But separately it will be necessary to allocate space for an office, staff rooms and storage facilities.

Mandatory requirements for the premises:

- Powerful ventilation.

- Temperature indicators - 16-18 ° С.

How profitable is the planned business?

The sale of composite reinforcement will only bring consistently high incomes when all manufactured products are shipped to customers. And therefore, we throw all our efforts into the search for wholesale customers.

The sale of composite reinforcement will only bring consistently high incomes when all manufactured products are shipped to customers. And therefore, we throw all our efforts into the search for wholesale customers.

The use of composite reinforcement is quite extensive, and its customers can be:

- Major developers.

- Companies specializing in interior decoration.

- Construction shops, bases and warehouses.

Sales finished products large wholesale will bring much higher profit. But here you should not bypass buyers from the niche of small businesses.

To indicate the profitability of the planned business, it is important to calculate the capital costs.

This may include:

- Registration of an enterprise - from 20,000 rubles.

- Purchase and commissioning of equipment - from 900,000 rubles.

- Preparation for the work of the premises - from 300,000 rubles.

- Purchase of raw materials for the production of the first batches of products - from 500,000 rubles.

It turns out that according to the most minimal estimates, the launch of the workshop will require ≈1,700,000 rubles. Costs can be reduced to 1,300,000 rubles if you buy a used production line.

The workshop of medium capacity produces up to 150,000 linear meters of finished products monthly. The current cost of composite reinforcement for wholesale market is 6-10 rubles / linear meter. In this scenario, an entrepreneur can have revenue of up to 1,500,000 rubles per month. But it's still not a net profit. To get the figure we need, the variable costs that the composite reinforcement for the foundation will require during the manufacturing process should be subtracted from the revenue:

- purchase of raw materials,

- payment of taxes and wages employees

- transport and communication costs,

- communal payments.

As practice shows, a medium-sized workshop can bring its owner up to 100,000 rubles net profit monthly. It turns out that in less than 2 years it is quite possible to recoup all the investments invested in the launch of the enterprise. But these profitability figures are achievable only if the products are fully sold.

In this material:

The production of fiberglass reinforcement, as one of the business lines, is promising and profitable, as it meets new trends in construction. Ease of installation and high technological characteristics make composite reinforcement in demand, and its production - cost-effective.

Fiberglass reinforcement has surpassed metal, thanks to improved technical specifications: high strength, resistance to prolonged exposure to water and aggressive media, inertness to electric current and electromagnetic effects. Fiberglass rods are elastic, the use of this material in construction can significantly reduce the heat loss of the finished structure.

Description of the business and approximate investments

The production of fittings belongs to the category of high-tech, in this case we are not talking about the organization of a handicraft workshop with minimal costs.

For the production of reinforcement based on glass beams, it will be necessary to install special equipment, an automated line. There is no lack of choice, the process is controlled by computer control and excludes manual labor as such.

Starting investments range from 1,200,000 to 1,700,000 rubles.

Product Description

The fittings are impregnated with a polymer binder and subsequently cured bundles of glass heavy-duty fibers. Due to the composition, fiberglass reinforcement:

- has a specific strength ten times higher than the corresponding indicator of metal elements;

- does not corrode, which allows it to be used in the construction of structures in sea water and in its immediate vicinity;

- reacts to temperature changes in the same way as concrete, protecting buildings and structures from cracking;

- has a service life of up to hundreds of years, does not harm the environment;

- non-toxic and does not accumulate radiation;

- does not create radio interference, magnetic field, inducing currents.

The advantages of the material are obvious, but they need to be supplemented by low weight, ease of installation (which does not require welding and special construction equipment) and cost savings of about 30%. The combination of advantages determines the wide range of use of fiberglass reinforcement:

- road construction;

- industrial and civil construction;

- fastening of heat-insulating materials;

- layered masonry in brick construction;

- reinforcing elements;

- cladding and carrier layer;

- drainage, sewerage, etc.

Production plan

The production of fiberglass reinforcement includes several stages, continuously replacing each other:

- Supply of fiberglass for processing threads with a solution of polymer resins. Getting roving.

- Transfer of the roving to the molding section. Obtaining reinforcement of the desired diameter.

- Passage of the roving through the polymerization chamber.

- Winding threads and embossing.

- Passage of blanks through the drying chamber.

- Cutting and packaging of rebar.

To obtain a rod of a given diameter, roving (glass bundles impregnated with polymer resin) is pulled through holes - dies. In the polymerization chamber support high temperature, under the influence of which the upper layer of fiberglass seizes, but in general the reinforcement remains soft enough to be wound into a reel and secure the ribbed profile. Subsequently, the finished reinforcement has the same ribbed surface, which provides excellent adhesion.

Scheme of the line for the production of fittings

Scheme of the line for the production of fittings The automated line is controlled by a specialist using a computer. Depending on the diameter of the die, it is possible to adjust the production of rods from 4 to 24 mm in diameter.

The room in which the equipment will be installed should be about 30 m long, the ceiling height should be about 3 m. Sanitary standards regarding lighting and ventilation of the room must be observed without fail. The preparation of the workshop will cost about 300 thousand rubles.

The production line, depending on the capacity, produces from 10 m of rebar per minute. The cost of equipment starts from 1.2 million rubles. Used equipment in good condition can be purchased much cheaper. However, the purchase from the manufacturer involves the installation of a workshop line, service and warranty service, the purchase technological scheme and training of staff in the field.

The set includes: cutting device, pulling device, rib twister, impregnation bath, cooling bath, polymerization chamber, creel, automatic process control station.

The line should provide for the possibility of changing the diameter of the reinforcing bars without stopping the process. Most lines allow you to produce 2 (3) bars at the same time.

Accessories:

- glass threads;

- binder - polymer (epoxy) resin, hardener, plasticizer, catalyst).

To establish a round-the-clock work, 3 teams will be required, including 2 operators (with the simultaneous production of two bars) and an auxiliary worker, whose duties include control of the rebar winding, storage and transportation.

organizational plan

Management is assumed by the owner of the enterprise. For paperwork, it is advisable to register an IP.

The senior operator of the workshop is directly subordinate to him, at whose disposal are the operator and the auxiliary worker.

A growing production will need a full-time technologist (preferably with special education and work experience), sales specialists, and an accountant.

Financial plan

Initial costs include the purchase of equipment - from 400,000 rubles, the purchase of raw materials - from 200,000 rubles, the preparation of the workshop and commissioning - from 600,000 rubles.

Fixed costs include payment utilities, phone and internet, employee salaries, taxes, rent, advertising costs, depreciation, selling and management expenses. The amount is 120-150 thousand monthly.

Sales and Marketing

Sales of products are carried out in two directions:

- building objects of the region;

- retail.

The first category should be 85-90% of sales, only in this case the company can count on making a profit. Collaboration must be ensured at all levels, from designers to contractors and subcontractors.

High competition forces the owner to look for opportunities to interest the buyer, for example, by providing discounts, providing delivery.

In addition to direct competition, manufacturers of steel reinforcement have firmly established themselves on the market. A technical specialist should be able to correctly justify the advantages of manufactured products, the commercial department should work closely with organizations dealing with the construction of chemical plants, structures exposed to aggressive environments.

Possible risks

High competition demands competent work sales representatives that ensure the implementation of the sales plan. The seasonality inherent in all sectors of construction should be taken into account.

Profits may be affected by a decline in construction volumes in general. It is necessary to work ahead of the curve, provide for and ensure the conclusion of contracts for the supply of products, and look for new markets.

Rising prices for raw materials inevitably threatens to increase the cost of products or reduce profits. To minimize risks, you should conclude long-term supply contracts at a fixed price, work with trusted suppliers.

The payback of production, established from scratch, is from 6 months, subject to an established 100% sales and High Quality products. High competition implies extensive ties with suppliers and consumers, promotion and advertising, close cooperation within the construction market within the region and beyond.

Order a business plan

| Investments: Investments 3 000 000 - 6 000 000 ₽ Specialization of the Moscow Jewelry Factory - production and sale jewelry from precious metals and stones. Today, the company is the country's largest manufacturer of diamond jewelry. MUZ is part of an international holding. The holding of companies carries out a full cycle of production and sale of jewelry: Diamond cutting enterprises Own production of jewelry (includes two… |

| Investments: Investments 1 400 000 - 1 800 000 ₽ The Krown® brand was founded in 1986 in Canada. Currently, more than 1000 integrated corrosion protection stations are successfully operating in the world. The unique product T40, which was specially developed by the company's engineers, allows you to comprehensively protect vehicles from harmful effects environment. The composition of the inhibitor is protected by a patent, production is organized only at the Krown® company factory in Canada. Every year more than 1,000,000 vehicles… |

| Investments: Investments 150,000 - 198,000 ₽ Construction market in Russia continues to grow steadily, selling construction services and materials with us you can be calm and confident in tomorrow. Let's see what we earn on: Sale of non-metallic materials from a quarry (sand, crushed stone, asphalt gas, gravel, slag, peat, etc.) Special equipment services (we successfully cooperate with more than 150 owners of special equipment, whom we attract by our… |

| Investments: Investments 499,000 - 1,500,000 ₽ The Avista Module Engineering group of companies has been innovating and creating trends in the prefabricated construction market for 11 years. Founded by Kulubekov Vadim Ravilevich. The company specializes in providing complex services for the design, production, delivery, construction and assembly of prefabricated buildings for administrative, domestic and industrial purposes. Products are manufactured at a plant in Novosibirsk. The company's product range includes collapsible cabins, modular dormitories, modular canteens,… |

| Investments: Investments 150,000 - 750,000 ₽ SOFTIUM schools have created a special environment for developing interest and programming skills in children from 6 to 14 years old. In a short time, we have won the trust and love of hundreds of children in different cities of Russia, as well as in Kazakhstan. When creating our school, we took into account and eliminated all the shortcomings of conventional computer courses and programming courses for children. V… |

| Investments: Investments 450,000 - 800,000 ₽ We have been working in the LED lighting market for over 5 years. Expert and practical experience allows us to implement lighting projects of any complexity. Today, our portfolio includes more than 100 objects, our partner portfolio includes the largest manufacturers, our team includes the best specialists in the industry. Our product is the most modern and energy efficient sources to date… |

| Investments: Investments 550,000 - 2,000,000 ₽ Open your chemical production with NPK AtomChem! You will be able to produce products in your region: auto chemicals and auto cosmetics antifreeze antifreeze and antifreeze household chemicals liquid soap prof. chemistry for enterprises. You can implement it, offer best price than dealers for similar products. Research and production company "AtomChem" works in the field of chemical production for over 6 years now... |

| Investments: Investments 4 000 000 - 8 000 000 ₽ INGLOT is a wide network of branded salons of European professional decorative cosmetics and skin care cosmetics. Our brand is independently engaged in the creation of cosmetic products, accessories and equipment, currently uniting more than 700 outlets Worldwide. The mission of our company is to produce high quality cosmetics at an affordable price for everyone. These are products you can trust... |

| Investments: Investments 1 000 000 - 2 000 000 ₽ In 2016, the company made a full launch automated production joint venture "First furniture factory-ALNO", rebranding of the factory, new the lineup for various segments and premium kitchen brand Bruno Piatti. A joint venture with the Piatti Factory has made it possible to produce kitchens according to Swiss quality standards. To date, the First Furniture-ALNO is: -52,000 m2 of production and storage space. - Capacity -50000 sets of furniture... |

| Investments: Investments 75 000 ₽ We have been producing unique "Norwegian Houses" for 5 years. We offer you to open the production of "Norwegian Houses" in your region and earn 2.5 million rubles. in year! The uniqueness of the "Norwegian Houses": A residential 2-storey house for permanent residence, with an area of 33 sq.m, is assembled in 1 day and costs only 590,000 rubles! The house is manufactured in the factory, ready to be transported and mounted ... |

| Investments: Investments 1 500 000 - 3 500 000 ₽ H-Point is a workshop providing services for the production and repair of high pressure hoses and rigid pipelines. The first H-POINT enterprise was opened in 2010. Today, our workshops successfully operate in Russia, the Republic of Belarus and Kazakhstan. The idea of creating such workshops came from the Gidravia company, the largest supplier of equipment for the manufacture of hoses, high pressure hoses and… |

| Investments: Investments 990,000 - 1,500,000 ₽ Senor Doner is a regional network of grill cafes. We use modern technologies analytics and optimization to create a business that will work for decades, improving day by day. Our Menu consists of a wide selection of dishes. The main dishes include locomotive products - doner kebab (shawarma) and shaverbox, there are also other groups of products - snacks (Potatoes… |

1. We analyzed the target audience, product, regions for promotion, competitors and USP.

1.1. We understood what problems there are in the market that can be turned into advantages.

- A large number of competitors supply Chinese pipeline fittings. These are low quality products that quickly fail, for all quality issues you need to contact China;

- Not all suppliers of domestic pipe fittings can provide product quality certificates;

- Suppliers often have to place an order with 5-10 suppliers, due to the fact that one manufacturer is not able to produce the entire range of pipeline valves, often even manufacturers do not have the necessary products in stock;

- On the market great amount"outbid" and "garage" productions;

- Poor service: managers respond slowly to requests, do not call back, the customer himself organizes the delivery.

1.2. Identified the target audience.

In 90% of cases the contact with the company is carried out by the manager of the supply department:

Professional motivation:

- Deliver the necessary products, on time and of proper quality;

- Receive an award from management for a job well done;

Personal motivation:

- Do not spend a lot of time selecting contractors, controlling delivery and shipment from each of them;

- Career growth;

- Opportunity to receive bonuses from contractors.

1.3. Defined promotion regions.

1.4. Analyzed websites and promotion strategies of competitors.

1.5. Formed a unique selling proposition based on real market problems.

1.6. Developed a prototype of the future site.

2. We developed a “selling” site with a conversion rate of 8.7%

From the experience of creating sites for the sale of pipeline fittings, we know that the most important thing is to show the product "face". The smaller the nesting of catalog categories, the greater the number of titles presented, the higher the chance to receive an application. On such a site, people should not search for something, especially not search for a long time. Therefore, each product is no more than 1-2 clicks away, and the product pages, as well as the main page, made in the style of a landing page, provide comprehensive information in an accessible form.

We try to place all the most important information within the first screen. Noticeable headlines, block with key benefits ( own production and availability) and a large open shape leave no room for doubt - you have to take it. The specificity of the product allows you to focus on monitor screens, and the correct display on mobile devices- a nice bonus for those who order bends and valves from the phone.

One of the most important competitive advantages is that the Company itself is a manufacturer of the proposed pipeline and stop valves. To confirm this fact, we created the pages "Production" and "Certificates".

A bright and noticeable button "Make an Order Online" allows you to receive more applications

3. Launched contextual advertising in YandexDirect and GoogleAdwords

- Because advertising campaign launched on many regions and products at once, so that the budget is not distributed over many campaigns, we combined them into one, and moved the priority regions into separate campaigns.

- In order to determine from which advertising system the client receives more calls, we installed a number substitution on the site for clients from Direct and clients from Edwards.

- To show additional benefits of the campaign in the limited ad text, we have written benefits in sitelink text. In order to return customers who visited our site, but did not order anything, we set up remarketing and retargeting in advertising.

- So that the client immediately understands that he is dealing with a manufacturer, we clearly reflected this in the ads and on the website.

Contextual advertising indicators

4. Carried out SEO-promotion of the site

- Before the launch of the project, a complete internal optimization of the site was made. Therefore, all pages of the site very quickly got into the index of search engines.

- The site was originally designed to promote a large number of search queries. Therefore, the site: 19 categories, 51 subcategories and currently more than 270 individual product pages.

- One of the features of the search promotion of this project was the creation of separate pages for products in priority areas of activity.

Fiberglass reinforcement is a modern alternative to traditional metal parts. The organization of its production opens up interesting prospects for entrepreneurs. In this article, we'll show you how to make a . Let's outline some features of this business and "pitfalls", which, for a successful start, you need to know in advance.

Fiberglass reinforcement is in demand today in construction, but is beginning to be widely used in other areas of the economy.

This type of material is rapidly increasing in popularity, as it has a number of important advantages. Reliability of operation, ease of use and transportation are the reasons for the rapid increase in demand for it.

Key features of a business plan for the production of fiberglass reinforcement

Competent business planning for the production of fiberglass reinforcement is the key to success

The organization of any business requires investments and decision-making should be based on a detailed analysis of all factors. This is what is meant to be done business plan for the production and sale of fiberglass reinforcement.

Market research will allow you to understand the relationship between potential demand and existing supply. And also finding your competitive difference is an important key to success.

To determine the need for production space, equipment, raw materials, personnel, the technology and production process are being studied.

The result of the analysis of all this information will be the preparation of financial and investment plan. Business planning for the production of fiberglass reinforcement will allow you to weigh all the pros and cons, and you will make the right decision.

Description

Files

Key features of the business

The article discusses the launch of a business for the production of fiberglass reinforcement with the acquisition of a production line.

Consumers of products - installation and construction organizations, shops building materials, individuals.

The project is not characterized by high risk due to the fact that the material for the Russian market is new and in demand. In addition, the availability of raw materials, automated technology ensures the profitability of products.

1 - Summary

1.1. The essence of the project

1.2. The volume of investments to launch the production of fiberglass reinforcement

1.3. Work results

2 - Concept

2.1. Project concept

2.2. Description/Properties/Characteristics

2.3. Goals for 5 years

3 - Market

3.1. Market size

3.2. Market Dynamics

4 - Staff

4.1. staffing

4.2. Processes

4.3. Wage

5 - Financial plan

5.1. Investment plan

5.2. Funding Plan

5.3. Sales plan for the development of the production of fiberglass reinforcement

5.4. Spending plan

5.5. Tax payment plan

5.6. Reports

5.7. Investor income

6 - Analysis

6.1. Investment analysis

6.2. The financial analysis

6.3. Risks of fiberglass reinforcement production

7 - Conclusions

The business plan for the production of fiberglass reinforcement is provided in MS Word format - it already has all the tables, graphs, diagrams and descriptions. You can use them "as is" because it's ready to use. Or you can adjust any section for yourself.

For example: if you need to change the name of the project or the region where the business is located, then this is easy to do in the "Project Concept" section

Financial calculations are provided in MS Excel format - parameters are highlighted in the financial model - this means that you can change any parameter, and the model will automatically calculate everything: it will build all tables, graphs and charts.

For example: if you need to increase the sales plan, then it is enough to change the sales volume for a given product (service) - the model will recalculate everything automatically, and all tables and charts will be ready immediately: monthly sales plan, sales structure, sales dynamics - all this will be ready .

A feature of the financial model is that all formulas, parameters and variables are available for change, which means that any specialist who knows how to work in MS Excel can adjust the model for themselves.

Rates

Feedback from our clients

Feedback on the business plan for the production of paving slabs

The purpose of planning was, on the one hand, to attract funding, and on the other hand, we also wanted to have a clear picture of how we would develop. In the end, I liked the plan. In the business plan of the paving slab production workshop, I liked the financial model, I liked that it was convenient to use, it was easy to adjust it for myself, there were no questions about it in the bank either. So far, a loan of 19 million has been received. rubles. Thanks! This result was obtained, including with your help. Good luck!

Maksimov K.O., Moscow Nizhny Novgorod,

Feedback on the development business plan sand pit sand mining

To expand production, we needed to attract investors. More precisely, we had our own investor, but in order to work with him, we needed a business plan. Representatives of the site provided us with invaluable assistance in compiling this document, as a result of which the investor was satisfied with the quality of the business plan. We received investments in the amount of 40 million rubles for the purchase of new equipment.

Egor Valerievich, Kostroma, general manager

Feedback on a business plan for a concrete plant

We were satisfied with the business plan of the concrete plant. All formulas are easy to use and very simple, all explanations are clear, and in finished model you can make any changes. In fact, this is the first business plan that has proven to be user-friendly and clear to understand.

M. L. Ivanova, financial director, JSC "World of construction"

Feedback on a business plan for the production and sale of fiberglass reinforcement

After I resigned from the top position of one of the enterprises in our region, I did not want to go to work for hire at all. I decided it was time to start my own business.

During the construction of my country house, I encountered such building materials as fiberglass reinforcement. I became interested and began to study the topic - perspectively. Then I suggested to one wealthy friend that he also invest in this business, because my savings were not enough.

But it took calculations to convince him. There is no time to do it myself, and I am not a financial specialist.

I bought Plan Pro ready from the company business plan for the production of fiberglass reinforcement. We looked at it with a partner, we liked the competent structure of the project, the convenience of financial calculations and a complete analysis of the business that were in the business plan. As a result, I attracted investments in the amount of 15 million rubles and launched the project.

Veselov A.L., Novosibirsk region

Creating a business plan for the production of fiberglass reinforcement, where to start

Before creating a business plan, the initial conditions in which the business is planned are determined: type of product, geographical location, way of owning resources - rent or ownership, scale of the business, and others.

In this project, the production will be fiberglass reinforcement in the range - section diameter 4, 6, 8 and 10 mm.

The equipment is acquired in the property, the premises are rented.

The production technology is purchased with the equipment from the supplier.

Production volumes are planned at the level of a small or medium-sized enterprise.

Preparatory stages of the business plan

To make a decision to start production, it is important for an investor to know the amount of investments and the payback period.

They are calculated based on the volume of production not lower than the break-even point and the volume of possible sales. The calculation is made in detailed business plan.

Before proceeding with the calculations, they study the market, technologies, equipment features and requirements for the premises and staff.

Market analysis for fiberglass rebar business plan

Any business plan starts with a market analysis. Is there an opportunity to make money on it? To do this, the supply and demand at the local and regional level. Also do not forget about imports.

So, our product is a replacement for traditional metal fittings. The most compelling reason for replacement is cost, as well as lightness, no welding. This facilitates the construction process at times, especially the construction of the foundation.

Other benefits:

- anti-corrosion properties (10 times superior to steel reinforcement);

- cost-effectiveness (transportation is cheaper, replacement less often);

- magneto inertness;

- dielectric properties.

Due to these advantages, it is used for reinforcing foundations, automobile canvases, embankments, monolithic concrete. With its help, flexible connections are made between the brickwork, improve the characteristics of the walls. They are used in the production of road slabs and slabs, drainage pipes, dowels.

Use it both with rods and nets. Therefore, it is supplied in coils and rods with large reinforcement diameters.

Decorative brick is a fundamentally different, but also noteworthy direction in the construction industry. contains calculations related to the income and expenses of this business, as well as the payback period, profitability, etc.

POTENTIAL CONSUMERS

When compiling business plan for fiberglass rebar manufacturing company evaluate the volume of demand for all distribution channels and their development prospects. The market for fiberglass reinforcement is extensive: from small developers to large construction corporations. Shops and bases of building materials are also interested in this product;

As a result, we single out 3 distribution channels:

- Implementation to private developers.

- Realization to construction shops and firms.

- Sales to large construction companies.

The demand for these products is seasonal, coinciding with the construction season.

COMPETITIVE ENVIRONMENT

In progress business planning for the production of fiberglass rebar it is necessary to investigate the number of its producers in your area and the volume of supply. Find out the price range of products and additional services.

There is competition in this market. In addition, competitors are organizations selling metal fittings.

For competitive advantage it may be necessary to provide an additional service - to make a calculation and technical justification for the replacement metal fittings on fiberglass.

The result of this section business plan there will be a conclusion about the presence of prospects for the local and regional market of fiberglass reinforcement.

Stages of work and the necessary resources to start production.

In this section investment project for the production of fiberglass reinforcement are determined with the location of production, the characteristics of the premises and equipment, the number of personnel, the volume of raw materials.

PRODUCTION ROOM

The workshop does not require a large space. But there are features - the length of the room should be more than 21 meters, since the equipment consists of 7 parts, and they are on the same line.

You will need a power source with a capacity of 12-16 kW when starting and warming up the equipment, 4-7 kW later. Water supply and sewerage are also required;

Requirements for the equipment of the workshop according to the technology:

- Forced exhaust for the oven.

- Forced ventilation.

- Distance from residential buildings;

- Slope - no more than 5 cm;

- Air temperature up to 16–18 °C.

The summary of this subsection of the business plan contains the result of a study of proposals for renting premises, the average cost per month, plus utility bills and the cost of equipping the premises with a hood and ventilation.

EQUIPMENT AND TECHNOLOGY

Equipment and technology are purchased from a manufacturer who knows all the details of the production and marketing of composite reinforcement.

It is worth choosing a manufacturer that will provide the greatest guarantee and technical support, even at a higher cost of equipment.

There is Russian manufacturers who will deliver and debug the lines of small and medium volume production. Their main equipment components are imported.

The approximate cost of a line for a small enterprise (up to 5,000 m / shift) is from 1.5 to 1.7 million rubles. For a more productive line (up to 12,000 m / shift) - about 3.5 million rubles.

Delivery, installation and launch time is about a month. The manufacturer also conducts on-the-job training for personnel.

The process is very simplified:

- Glass roving is being prepared. This is the basis of future fittings. Its strength and other technical characteristics depend on it.

Molten aluminoborosilicate glass is drawn into filaments up to 20 microns thick, bundles are formed from many filaments, this is glass roving.

- Further, products of a certain length and diameter are formed from it.

The conveyor line works under the control of the program, it is automated, the parameters of the product are entered into the program by the operator-engineer.

In Russia there is normative base for the production of such fittings. All standards for the manufacture of composite polymer reinforcement are regulated by GOST 31938-2012

The result of compiling this subsection of the business plan is the choice of a supplier and a line in the required price range.

STAFF

It does not require many workers to maintain the composite rebar production line. Two operators are needed per line. For auxiliary work - an auxiliary worker.

- The senior operator monitors the production technology and is responsible for safety.

- Operator.

- An auxiliary worker controls the winding of the coil, transports the products to the warehouse and ships them.

- At the request of customers, an engineer makes a calculation and technical justification for replacing metal reinforcement with fiberglass.

Besides production staff, will need:

- Supervisor

- Accountant

- The sales manager issues invoices, checks payment and compliance with all terms of the contract.

- A sales representative conducts presentation meetings with potential customers, sends out commercial offers, and so on.

Transportation is carried out by the customer or a transport company.

Based staffing v business plan for a company planning to produce fiberglass reinforcement, calculate the monthly payroll.

RAW

For the manufacture of such fittings, it is important to use high-quality raw materials. The main consumable material is glass roving, to obtain it, aluminoborosilicate glass is used. You can add glass from recycling (recycling), this will reduce the cost.

Additional Consumables:

- epoxy resin;

- braided thread for winding reinforcement;

- ethanol;

- acetone;

- dicyandiamide.

Suppliers are selected based on the quality and price of raw materials, convenience and cost of delivery.

The volume of investments to launch the production of fiberglass reinforcement.

The calculation of investments depends on where the production will be located, on the equipment selected for productivity and, accordingly, on the production plan of the enterprise. Therefore, it makes no sense to give specific investment figures. But on our site you can order business plan for the production of fiberglass reinforcement with calculations. Everything will be calculated in it. required indicators depending on the given conditions of the project.

Let's designate the main investments that are planned at the start of the enterprise:

- Preparatory work (registration of an enterprise, acquisition of technology) XXX r;

- Acquisition of the production line XXX r;

- Rent of premises XXX r;

- Repair and equipment of the premises with an exhaust system XXX r.

- Purchase of a stock of raw materials XXX r;

- Working capital XXX r;

- Marketing and advertising on initial stage XXX p;

TOTAL:_________________

The volume of investments when starting this business is from 4-5 million rubles. This is the minimum level.

Income and expenses in the project for the production of fiberglass reinforcement

COSTS:

The company's expenses are the sum of fixed and variable (raw materials and electricity) costs.

FIXED COSTS:

- Rent

- Communal resources

- Equipment depreciation

- Payroll and contributions to social funds

- Advertising expenses

- Connection

- other expenses

VARIABLE COSTS per month are calculated based on the assortment, production plan, prices, specific consumption of raw materials and electricity.

INCOME:

The revenue consists of the market price by type of product (reinforcement with a cross-sectional diameter of 4,6,8,10 mm) and the planned production volume at a 40-hour working week.

Return on investment - the result of a business plan for the production of fiberglass reinforcement

According to the most cautious forecasts, this business, even on a small scale, can pay off in a year and a half or two, provided that the line is fully loaded and the goods are sold.

The structure of the financial model for the production of fiberglass reinforcement

The financial model is a separate file in MS Excel format - in fact it is

a separate product designed for business planning and calculation of all its

indicators. Each of the parameters of the financial model can be changed manually.

There are no macros in the financial model. All formulas are transparent and accessible to

changes.

In the process of working on a business plan, we look at dozens of different sources

information. These are data from equipment suppliers, and industry portals, and interviews with market experts, and official statistics - such system analysis data gives a complete picture of all project parameters: prices, equipment costs, premises costs, costs, etc.

A necessary component of a full-fledged business plan is a flexible sales plan. It is important, on the one hand, to have a forecast for the business as a whole, and on the other hand, to be able to see the profitability in the context of a separate profit center or even a separate product.

Download a ready-made business plan for the production of fiberglass reinforcement with financial calculations and an Excel model

The development of a business plan will allow you to determine the options for business development, calculate optimal volumes according to the conditions offered. Atlooking for an investor or to get a loan from a banka well-designed project is a must. If you do not have time to develop it, we suggest you download a sample ready business plan. The sample financial model will calculate all investment ratios for the plan. Moreover, it is possible to order an individual turnkey business plan, taking into account the specifics of your business, by clicking on the link below.

The construction industry is steadily developing, the achievements of science are being used more and more, modern materials are appearing. Therefore, the fiberglass reinforcement business has every chance of becoming highly profitable. But to make a confident decision, be sure to draw up a business plan.

- Production technology

- How much can you earn in the production of fiberglass reinforcement

- Similar business ideas:

fiberglass reinforcement, otherwise - "composite", is a hardened rods made of fiberglass and impregnated with a special polymer binder. In construction, such rods replace previously used metal structures, are used in the installation of concrete structures and building foundations. Their main differences are:

- lightness (weight is 5 times less than that of metal bars of the corresponding size and quantity);

- installation features - fastening with ties instead of standard welding;

- dielectric properties and lack of shielding specificity;

- high level of extensibility and increased strength of the material;

- 100-year guaranteed service life of the structure;

- resistance to corrosion, impact external environment and atmospheric phenomena;

- cheapness of production.

Ease of use causes demand for fiberglass reinforcement not only for industrial construction, but also for a wide range of domestic applications, for the installation of domestic greenhouses or small buildings.

Benefits of a fiberglass rebar business

For entrepreneurs who want to carve their niche in construction business, the production of fiberglass reinforcement is a good option for rapid development and income generation. Outdated metal structures are being replaced by more profitable composite reinforcement, and the increasing needs of the repair and construction industry guarantee a high purchasing power of this product. The production of fiberglass reinforcement does not require the involvement of a large number of employees to perform the work. The approximate period of production self-sufficiency and reaching profitable indicators is about six months, which allows us to speak about the profitability of production and the prospects for investing in business. The positive side is the benefit of the production of fiberglass rods, due to the low cost of the initial raw materials and relative cheapness. necessary equipment. The units that make up the production line are relatively compact and are serviced by only 2-3 workers involved in the production of composite rods. The price of fiberglass rods is one third lower than that of metal counterparts, therefore, the consumer demand for products with high quality indicators, which at the same time saves estimated costs, is steadily increasing. Taking into account the rapid creation and development of various firms and companies seeking to join commerce in time and have time to conclude long-term contracts for the supply of materials to developers and contractors, the competitiveness of the enterprise and, accordingly, successful implementation composite reinforcement will be higher at production organizations that have earned the trust of consumers.

Step-by-step plan for opening the production of fiberglass reinforcement - Requirements for the premises, GOSTs

The first step in preparing for the start of production is the selection of premises that meet the requirements for workshops that house complex equipment. For the accuracy and success of high-tech manufacturing of fiberglass rods, the following conditions must be met:

- the minimum length of the workshop - from 25 meters;

- a flat floor in the room, the maximum level difference is up to 4-5 cm;

- constantly maintained optimal air temperature (about 16 degrees);

- the presence of high-quality, uninterrupted ventilation with established outflow parameters from 0.25 cubic meters. m per minute;

- ceiling height - from 3 meters (permissible limit - from 2.5 meters);

- the possibility of a passage width of 1.5 meters between production lines.

It is necessary to have convenient access roads and the presence of a warehouse for storing products in order to avoid clutter production premises finished products. It is worth doing in advance and logistics calculations, allowing to develop a clear schedule for the supply of raw materials and form a scheme for sending products for sale. This will avoid delays in the production of fiberglass rebar and prevent the formation of surpluses of goods.

Technology for the production of fiberglass reinforcement

The technology for the production of composite rods is inherently quite simple, but it implies a clear implementation and observance of the procedure for manufacturing products. The process consists in the initial impregnation of glass fibers with a special resin and the subsequent formation of rods of the required diameter in the aggregates intended for this, polymerization and the application of a fixing layer. The quality of the produced fiberglass reinforcement depends on the selection of the constituent raw materials and technological process production. The raw materials are the following ingredients:

- fiberglass;

- synthetic resins (phenol-aldehyde - hardening in the process of polymerization and polycondensation, epoxy - not polluting the environment with side emissions during the production process);

- polymers - a variety of resins, polybenzothiazole, polybenzimidazole and polyamide (during production they require the addition of other resins);

- ethanol (ethyl alcohol), dimethyl ketone (acetone), hardener - dicyandiamide.

Mandatory components for fiberglass rods are rovings (wire threads) used for winding rods and reinforcing the product. The production stages are automated, the business requires minimal human effort in the process of manufacturing composite reinforcement, however, constant monitoring and maintenance of the production line by professionals is required. Production stages:

- Immersion of the starting material (continuous strands of fiberglass) in a resin impregnation vessel with hardening components in the composition.

- Removal from the details of the wire that served to give relief.

- Pulling the resulting rods through a high-temperature polymerization chamber.

- Reinforcement surface relief creation by means of winding and profile fastening.

- Cooling and drying of blanks.

- Supply of roving to the spinneret, formation of a rod of the required diameter and configuration.

- Stretching of finished rods, final dehydration and, if necessary, coiling or stacking parts cut to the required length.

Until 2014, clear standards for the standardization of fiberglass rods in the post-Soviet space were not defined. Manufacturers either used the parameters adopted in the countries of America and Europe, or did not certify their products. GOST 31938-2012, which entered into force in January 2014 and was adopted by 8 countries (Russia, Belarus, Moldova, Armenia, Kyrgyzstan, Azerbaijan, Tajikistan and Uzbekistan), regulates the indicators and requirements for the production of fiberglass reinforcement. The rules describe the methods and methods of product quality control and define the exact limits of the content of substances to minimize harm to the environment. The text of the document contains normative references, classification and technical requirements required for production.

How to choose equipment for the production of fiberglass reinforcement

When opening an enterprise for the production of reinforcement from fiberglass fibers, it is necessary to equip the workshop with specialized equipment. You can either purchase and install a fiberglass processing line in parts, selecting individual units, or purchase a ready-made set of special devices that provide the entire workflow. For the most part, the machines are universal and suitable for the production of composite rods of various diameters (from 4 to 24 mm), which allows expanding the range of products depending on the level of demand for a particular type of rods. For the uninterrupted operation of production lines, it is required to ensure a sufficient level of voltage in the network (equipment operation requires 380 V, 50 Hz), take measures fire safety and conduct a thorough briefing of persons with access to the machines. The complete line consists of the following parts:

- bath for impregnating threads, equipped with spin functions and a set of spinnerets;

- guillotine-type mechanism for cutting rods;

- polymerization oven with temperature control;

- cooling unit;

- device for pulling reinforcement;

- apparatus for twisting threads and winding ribs of rods;

- apparatus that twists finished products into coils.

In total, the length of the entire structure reaches from 15 to 20 meters, in width it takes from 0.5 to 1 meter. The arrangement of the workshop should be designed in such a way as to leave the space required by technological standards around the machines and ensure the unhindered movement of maintenance personnel. The list of equipment of the company also includes loaders, with the help of which finished products will be transported to warehouses, equipment for weighing and measuring products, devices responsible for the ventilation system of the workshop, supporting the required temperature regime indoors and built-in fire protection of the building.

What documents are needed to open

Registration of a business for the production of fiberglass equipment is carried out according to the standard scheme adopted in the Russian Federation for opening small and medium-sized enterprises. The procedure established by law regulates the actions for the official registration of a private company. The first step for a novice entrepreneur is usually to contact the state registrar, who clarifies the composition of the initial package of documents being prepared for submission to the state registration authorities. In accordance with the law of the Russian Federation "On state registration legal entities and individual entrepreneurs”, issuing a business registration certificate takes about a week. The documentation package submitted to the registration authority includes:

- application of the appropriate form;

- copies of identity documents (for individuals) and a selection of documentation on the creation legal entity, including authorized papers;

- receipts confirming the payment of state duty.

Appeal to the registration authorities takes place at the place of residence individual entrepreneur or in accordance with the location of the legal entity. Submission of documentation is carried out directly by the owner or head of the business or representatives acting on the basis of a notarized power of attorney. All documentation must be in accordance with established by law forms and filled out properly, otherwise, the package of papers is returned to the submitter for revision.

Which OKVED to indicate for the business of manufacturing fiberglass reinforcement

The application for opening a business indicates the direction of activity that meets OKVED ( All-Russian classifier species economic activity). The production of fiberglass reinforcement as a separate field of activity is not included in the classifier, therefore it is supposed to select the most appropriate direction from the list available in the list. The following codes may be suitable:

- 23.19 - Manufacture and processing of other glass products, including technical glass products;

- 23.91 - Manufacture of abrasive products;

- 23.99 - Manufacture of other non-metallic mineral products not included in other groups;

- 23.14 - Production of fiberglass;

- 25.24.9 - Provision of services in the field of production of plastic parts;

- 36.63.7 - Manufacture of other products not included in other groups.

What taxation system to choose for the production of fiberglass reinforcement

An important issue for those wishing to open and develop an enterprise for the production of fiberglass rods is the planning of tax expenses. It is possible to clarify the taxation scheme and determine the approximate amount of deductions when submitting documents and registering the company with the tax authorities at the place of registration entrepreneurial activity. If we start from the standard calculations carried out when drawing up a business plan for opening a manufacturing company, then an approximate list of tax items will look like this:

- income tax;

- payroll taxes;

- land tax, transport deductions, etc.

Depending on the form of ownership, the types of specified activities, and even the geographical location of the workshop in Russia, the list of taxes that must be paid may change, or the possibility of reducing the amount of state fees by taking measures to minimize costs will become relevant.

Do I need permission to open?

To release products, you must have test reports according to the method of GOST 31938-2012. Where geometric formats, tensile and compressive test results, shear strength and resilience and determination of service temperature limits will be determined. Based on this, a conclusion is made on the compliance of the reinforcement with the parameters of GOST, a report on the stability and quality of production. And also a certificate of conformity of products to the requirements of regulatory documentation is issued.

Production technology

For the production of fiberglass reinforcement, the following materials will be needed:

- glass roving - a bundle of glass threads;

- resins, acetone, dicyandiamide and ethyl alcohol,

- braided thread - roving for rebar winding.

The process looks like this. Roving from a special mechanism enters the tensioning device, where it is assembled in the right order. Then this completed beam is dried and heated, then it is impregnated and pulled through the spinnerets, which set the desired geometric parameters. After that, the threads go to the winder, where the reinforcement rod is formed and a winding of a given thickness is wound on it. The rebar then passes into a tunnel oven to polymerize the resin in the impregnation. If sprinkling of products is needed, a device for this is provided at the entrance to the oven. After the furnace, the hot bundle is sent to a special bath for cooling. At the end of the process, the cooled reinforcement is cut in accordance with the specified dimensions.

How much money do you need to start this business

When planning the opening of a workshop or a mini-factory for the production of fiberglass reinforcing bars, it should be borne in mind that this business requires initial material costs, and entrepreneurs who do not have sufficient sums of money to invest them in a timely manner to start production should better find a more budgetary option for production activities. It is possible to calculate preliminary investments, starting from the specific conditions and the available property and equipment of an individually taken business entity. Estimated costs will consist of the following expenditure items:

- Purchase or lease of a land plot on which production is supposed to be located (the cost depends on the location and size of the territory).

- The cost of procurement of raw materials (from 300 thousand rubles per minimum output).

- The cost of registering an enterprise and organizational activities is 20-50 thousand rubles.

- Transport and Communal expenses(from 100 thousand rubles).

- Purchase and installation of an integrated line for the production of fiberglass equipment (the price fluctuates depending on changes in the exchange rate, the brand of manufacturers of units and machine tools and the condition of the devices. According to a rough estimate, the cost of one line is from 800 thousand to 1.5 million rubles).

- The cost of building or renting a production facility (from 50 thousand rubles).

- Repair or re-equipment of the workshop in accordance with the requirements and safety standards (depending on the condition of the existing premises, on average it costs 200-300 thousand rubles).

- The payroll fund for employees (the mandatory amount of wages is calculated, regardless of the start of making a profit at the first stage of activity - 200-300 thousand rubles).

- Reserve stock of material resources for unforeseen expenses - from 50 thousand rubles.

The list of estimated costs can be quite long. And the task of any businessman is the need to independently or with the involvement of third-party specialists to calculate all possible cost flows - both before making a profit from the manufacture of products, and in the process of increasing the turnover of their own business. It is advisable to start production, having an initial capital of 1.5-2 million rubles, this amount is the minimum for investing in a business.

Popular

- Program for changing the angle of attack and pitch

- Actual output speed Calculation of closed gear train

- What is the procedure for the use of official transport by an employee

- aircraft fuel system

- Agreement for the evacuation of a vehicle Standard agreement for the evacuation of a vehicle

- Bulldozer performance and how to improve it Basic information about bulldozers

- Toyota Production System (TPS) and Lean Manufacturing

- Examination tickets by profession line pipe fitter

- What to do if you don't feel like doing anything

- Globus - shops for the whole family