Average performance is calculated as a ratio. Key indicators and formula for calculating labor productivity

is a factor that determines its effectiveness. It is determined by the volume of output produced per unit of time.

Conversely, the amount of time required to produce one unit of product is called labor intensity.

Usually, under performance, its actual indicator differs, but economiccybernetics introduces terms current and potential performance.

In this way, labor productivity growth- this is a decrease in its costs, for a given period of time for the manufacture of a unit of output, or an increase in the production of this product per unit of time. This directly leads to an increase in production efficiency.

Calculation algorithm

The calculated performance can be compared with the same indicator of the previous period and allows you to draw a conclusion about the development trends of the enterprise.

Trends can be both objective factors (seasonal), the introduction of a new tool, and subjective factors - morbidity, miscalculations in the organization of the technical process, and so on.

Formulas for calculating actual performance

The calculation is made from the observed actual results of the production process.

It looks like this:

- PT fact \u003d O pr: T fact

- Oh pr - the volume of output;

- T fact - time required for production.

Cash labor productivity- this is a calculated indicator that indicates the possibility of producing a certain amount of products under the prevailing conditions (available equipment, available materials and tools used).

This indicator is calculated from the ratio:

- PR max \u003d O max: T min

- Oh max- the maximum possible volume of production in units of their accounting;

- T min- the minimum labor costs for the release of such a volume in units of time.

Potential Performance- a calculated indicator of the volume of production using advanced technologies used in the world, advanced equipment in theoretically achievable ideal working conditions.

Expressed as:

- PR sweat \u003d O id: T min

- Oh id- the volume of production in ideal production conditions;

- T min– minimum labor input in the form of time.

Labor productivity per worker

PT \u003d (O x (1 - K pr)) / T 1.

O- the volume of manufactured products;

K pr

T1

Labor productivity according to the balance is calculated by the formula:

Fri \u003d (2130 line x (1 - K pr)) / (T 1 * H).

Performance with cost allocation

For a targeted analysis of investments, the use of an indicator of labor productivity with attribution of costs is of decisive importance.

From the standpoint of evaluating the effectiveness of investment costs, it is not so much the volume of manufactured products that is important, but the amount of costs for its release.

When investing capital investments, it is fundamentally important to consider economic efficiency, otherwise it is possible to reduce the profitability of capital investments and as a result, instead of capital gain, you can get the result in the form of its decrease.

Performance relative to costs incurred- this is the number of products received per ruble of funds spent. Attributable costs are the proportion of costs attributable to the production of a given volume of output, which falls on one employee per unit of time.

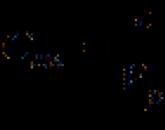

The formula for productivity taking into account costs will be:

- PZ- productivity, taking into account costs, unit of account / ruble;

- O- volume of production, units. accounting / ruble;

- W– costs incurred, hours/unit;

- T1- labor costs of one worker (part of the time spent on the production of the quantity of products per worker, hours);

- H– headcount workers, staff units;

- K pr– coefficient taking into account downtime (from 1 to 0);

- KZ– incurred capital expenditures, rubles/hour x unit;

- EZ– related operating costs, rubles/hour x unit;

- R- incurred repair costs, rubles / hour x piece;

- FROM– tax expenses, rubles/hour x unit;

- H– related taxes, rubles/hour x unit;

- dr- other expenses, rubles / hour x pcs.

Analysis

The need for analysis in the process of production management - an objective necessity for the choice of means and determining the directions of influence on it.

The need for analysis in the process of production management - an objective necessity for the choice of means and determining the directions of influence on it.

The introduction of a new, more advanced cutting tool can have such an impact on production.

Already comparing the 10-day period "before" and "after" the introduction of productivity will provide primary information about the positive or negative effect of innovation.

More accurate data statistical analysis can be obtained later by comparing longer periods.

An analysis of the labor productivity factor alone cannot give complete confidence to make a final decision.

This requires a cost analysis, an analysis of labor productivity with related costs, an analysis of economic efficiency. Considering all the results in the aggregate, you can be confident in the correctness of the decision.

Cost including costs

Cost price with accounted costs- an indicator of the inverse of labor productivity, that is, it is the value of the cost of one unit of output.

- C \u003d 1 / PZ \u003d Z / P, where

- C - cost price, taking into account costs, rubles / accounting unit;

- PZ - labor productivity, taking into account the costs incurred, unit of account / ruble;

- P - productivity, unit of account / hour x piece;

- Z - related costs, rub / hour x pcs.

Example of calculating performance with costs

The productivity of 500 "garne lads" for digging a trench along the Russian border is 60 m 3 / hour, for a bulldozer - 75 m 3 / hour. But simple performance is not important, namely performance with costs. We compare the productivity, taking into account the costs of diggers, and the same indicator of a bulldozer.

The cost of one hour of work of excavators is 90 UAH/hour, the cost of wheelbarrows and shovels is 5,000 and 250,000 UAH, the cost of a bulldozer is 3.58 UAH, the cost of diesel fuel for a bulldozer is 588 UAH per hour of work, the salary of a bulldozer operator is 360 UAH per hour of work. Regulatory term operation of shovels and wheelbarrows - 1 year, bulldozer - 5 years. During this time, the operating costs will amount to 100,000 UAH.

Calculate the profitability based on the price for excavation 25 UAH / m 3:

- Calculation of labor productivity of diggers: P earth \u003d 60 x (1 - 0) / 500 \u003d 0.12 m 3 / hour x piece.

- Bulldozer performance calculation:(0.667 - the coefficient of use of the working time of the bulldozer - the time spent on moving): P bul \u003d 255 / (1 - 0.667) / 1 x 1 \u003d 75m 3 / hour x piece.

- The ratio of the performance of a digger and a bulldozer: P bul / P earth \u003d 75 / 0.12 \u003d 625 times.

Labor productivity of one digger, taking into account the allocated costs:

- Allocated costs: Z \u003d 90 + (5000 \u003d 250000) / 42 weeks x 5 days x 8 hours / 500 pcs. = 90.3 UAH/hour. PZ zem \u003d 0.12 / 90.3 \u003d 0.0012289 m 3 / UAH.

- Cost price with expenses for excavation of 1 cubic meter of soil by diggers: 1/PZ land = 752.5 UAH.

- Profitability of a digger\u003d payment per cube / cost of excavation 1m 3 \u003d (25 / 725.5 - 1) x 100% = -96,68%

Productivity, taking into account the related costs of the bulldozer operator:

- Allocated costs: Z \u003d 360 + 558 + (3580000 + 1000000) / 5 years x (38 weeks x 5 days x 8 hours / 1 unit = 1550.63 UAH / hour.

- PZ bull= 75/1550.63 = 0.0484 m 3 / UAH.

- The cost price, taking into account the costs of the bulldozer, will be 1 / 0.0484 \u003d 20.66 UAH / m 3.

- Bulldozer Profitability: excavation payment 1m 3 / excavation cost \u003d (25 / 20.66 - 1) x 100% = 21%.

- PZ bull / PZ zem = 0.0484 / 0.000796 = 60.8.

For a ruble of costs, a bulldozer produces 60.8 times more than a digger.

Average performance

A certain amount of production for a fixed period of time, divided by the time spent for this - SCHP = O/T, where O is the output for the time period in units. accounting, T - elapsed time.

There are several levels of performance indicator:

- average hourly productivity.

for instance: 132 blanks were produced for a full work shift - 8 hours, SCHV = 132/8 = 16.5 pieces / hour;

- average daily performance.

For instance: 2780 blanks were produced per month, while the working time fund amounted to 21 working days CdV = 2780/21 = 132.4 pieces / day;

This is how productivity is calculated for any period based on actual data and an objective analysis of the influence of various factors on the state of production is carried out.

The Russian Economy in the System of International Labor Productivity

High performance is the main condition for sustainable economic growth.

In Russia productivity is at the level of about 26% of its size in the USA.

The Russian government sets the goal of achieving productivity growth of about 6% per year, so that by 2022 per capita income growth will be doubled.

The three most important factors behind Russia's productivity gap are:

- Low efficiency of labor organization.

In different industries, this factor determines from 30% to 80% of the backlog.

- Moral and physical depreciation of equipment and the use of inefficient technologies.

Almost 40% of thermal power plants operate on old equipment; in metallurgy, 16% of steel is produced in open-hearth furnaces. In general, by industry, this factor determines 20-60% of the backlog.

- Features of the current structure of the economy.

This factor determines the 5-15% lag. The low level of income determines the low level of lending, reducing the level of domestic investment. The lack of technologies and equipment in metallurgy for obtaining a high-quality product determines the low quality and efficiency of goods in this industry.

The essence of increasing labor productivity in Russia

Labor market research shows that in the conditions of Russia, the trend of traditional orientation to the labor process prevails.

- This is the desire for a calm, measured rhythm of work and there is no desire, by increasing its intensity, to receive higher incomes to meet their basic needs.

- Even calm relations in the team and regular payment of wages are preferable.

The reason is the low training of management personnel who do not have the skills to improve production efficiency and their disinterest in such a process.

Paradox - Russia does not develop small and medium business , which is the engine of increasing productivity around the world.

It is explained by the following reasons:

- low business security from the arbitrariness of officials;

- high cost and low availability credit resources;

- severe consequences in case of unsuccessful outcome of business ventures.

It is known that many American tycoons have repeatedly started the business from the beginning, having suffered a fiasco.

Labor productivity in non-productive sectors of the economy

Non-manufacturing part of the economy- this is the part that does not produce commodity resources. As a rule, it takes part in the distribution process (wholesale and retail), serving the population (tourism, medicine), creating cultural values (cinema, theater, museums, etc.).

In a word - the service sector, which provides the production process and the process of reproduction of the population.

The main opportunities for improving productivity lie in the following planes:

- simplification of regulatory factors in the field of commercial real estate. It just needs to be enforced. existing laws, partially revise SNiPs, reduce the number of approvals;

- improving the quality of communal and road infrastructure will provide an opportunity for easier access to commercial real estate, improved logistics and reduced inventory at warehouse facilities. This will help to accelerate the turnover of working capital, that is, to increase economic efficiency;

- improving operational efficiency. A significant increase in productivity can be obtained by increasing the centralization of administrative functions, optimizing the number of staff, and improving the quality of supply and demand planning.

Performance Management Strategy

The main strategic directions for solving the set task:

- Financial improvement - the technical base of the enterprise. Automating the functioning of business processes is the basis for increasing productivity.

- Modern ways production management based on continuous training of middle management.

- Minimization of costs per unit of production is achievable by reducing non-productive costs. Conducting regular audits of business processes will contribute to the timely identification of points of formation of such costs.

- Organization of a special regulatory framework will allow you to work out the optimal circle official duties for every manager.

- One of the highlights is the optimal organization labor process, including the ethical component - equipping rest rooms and creating optimal sanitary and hygienic conditions.

- An important factor productivity is With social orientation of the enterprise policy directed at the employee.

- An effective policy to increase staff loyalty in relation to the company by involving him when considering the prospects for the management and development of the enterprise.

- No methods of influencing performance will be effective without a well-developed system. its evaluation and the system for evaluating the results obtained.

The considered indicator is universal for analyzing the state of production.

DEFINITION

Product development is an indicator of the volume of production (work performed, services rendered). Output reflects the volume of output per unit of labor input.

The production formula is of great importance, since the calculated indicator is used when calculating labor productivity at the enterprise.

Output is an indicator that is directly proportional to labor productivity, so the more products are produced for each unit of labor costs, the higher the level of productivity will be.

The output formula looks like this:

B = Q / T

Here B is the performance indicator,

Q is the volume of output;

T - labor costs of a given volume of production.

Before calculating the level of labor productivity, it is necessary to measure labor costs and output.

labor costs include one of two indicators:

- the number of workers involved in the production of a given volume of products,

- hours worked, measured in man-hours (days) worked.

The following indicators are used to calculate labor productivity:

- average hourly output, which is determined by the formula:

Hour.=Q/T

Here Q is the volume of production,

T is the actual number of man-hours worked by workers.

- average daily output

Int.=Q/T

Here Q is the volume of production,

T is the actual number of man-days.

- average monthly (quarterly, annual, etc.) output.

Vmes.=Q/N

Here Q is the volume of production,

N- average headcount workers per month.

Methods for determining output

Methods for calculating output can be classified according to units of production volume:

- natural method (or conditionally natural), used in the production of homogeneous products at individual workplaces, by production teams. This method determines the output of a particular type of product (work or service), so the output will be expressed in physical units.

- the cost method is carried out according to the cost indicators of manufactured or sold products (it is used if the enterprise produces heterogeneous products).

The cost method has become more widespread, but it has a drawback. In the case when the calculation of labor productivity (PT) is carried out on the basis of manufactured or sold products, the indicator of labor productivity may be overestimated. This is due to the fact that the result includes the cost of past labor (the raw materials and materials used, the volume of cooperative deliveries, etc.)

This shortcoming can be eliminated by calculating the output based on net output (profit) or by calculating the profitability of labor, which reflects the ratio of profit and costs.

Examples of problem solving

EXAMPLE 1

EXAMPLE 2

| Exercise | The company works in shift mode with a shift duration of 12 hours. Downtime - 40 minutes Time spent on 1 operation - 8 minutes, |

| Solution | The formula for the production in accordance with the number of workers is: Q - number of products, Here N is the number of workers. Shift duration in hours: 12*60=720 minutes. We find the time of actual work completion by subtracting downtime from the total working time: 720 - 40 = 680 minutes. Within 680 minutes, 680/8=85 operations are performed. 85 * 2 = 170 products are made in 680 minutes. |

| Answer | The production rate is 170 products per shift. |

Currently, many tools have been developed to analyze their own performance. These indicators include labor productivity. Its calculation formula is simple. And the result will show how effective the work of the staff is.

Performance

Labor productivity is an indicator of labor efficiency. It determines the result of labor in quantitative terms at a certain point in time.

The following indicators speak about labor productivity:

- production;

- laboriousness;

- labor productivity index.

These indicators will reveal how many units of products can be sold (produced) in the company. Based on these data, it is possible to generate a production forecast, build a sales plan.

How to define output?

Output is the total amount of work performed by one employee. This indicator can measure the results of the sale of goods, services, production.

You can calculate the production rate by two values:

- the average number of employees participating in manufacturing process;

- time spent creating the product.

In the first variant, the calculation of production will be as follows: V=V/N

B - production;

V - the amount of work performed;

N is the average number of specialists directly involved in production.

The second option (based on the time spent): B = V / t

B - production;

V - volume of released works (actual release finished products);

t - actual labor costs per unit of time of interest.

How to define labor intensity?

Labor intensity - the amount of time spent by one worker on the production of one unit of service (goods). That is, it is the inverse coefficient in relation to production.

T - labor intensity;

N is the number (average) of specialists;

You can calculate the indicator per worker. Then the value of N must be equal to one.

T - labor intensity based on the time spent;

t - actual labor costs per unit of time of interest;

V - the volume of the released product (the result of work or service).

Labor productivity. Calculation formula

Several formulas have been developed for calculating labor productivity. When calculating according to any formulas, it is necessary to take into account that:

- the volume of manufactured products should be calculated in units of manufactured goods;

- only those personnel who are directly involved in production are taken into account (managers, lawyers, etc. are not taken into account).

The calculation of labor productivity, taking into account the factors of labor intensity and output, can be made using the formulas:

In terms of labor intensity: PT \u003d (V * (1 - Kp)) / (T1 * H)

PT - labor productivity;

T is the labor intensity of one worker;

Kp - downtime ratio;

V is the volume of output;

N is the average number of personnel.

Taking into account the production: PT \u003d [(In - Wb) / Wb] * 100%

PT - percentage performance indicator;

In - the development of products in reporting period;

Wb - production output in the base period.

Labor productivity. Balance formula

To calculate labor productivity indicators, you can use the balance sheet data of the organization. For example, an indicator of the volume of production.

Balance calculation formula: PT = (V * (1 - K p)) / (T * N)

V - the volume of manufactured products according to the balance sheet (reflected in line 2130);

Kp - downtime, coefficient;

T - labor costs of one employee;

N is the average number of employees.

The ultimate goal of any entrepreneurial undertaking is to make a profit. A businessman or enterprise uses the complex necessary resources: goods, raw materials and materials, energy sources, property and technical means, new technologies, labor force and services of various organizations.

To obtain a positive result, it is necessary to accurately determine the economic effect from the use of all elements of these resources.

What is it, why count

Every employer dreams that the staff he hires can do as much work as possible in a shorter period of time. For average calculation of the efficiency of the work of the workforce performance indicators are used.

Every employer dreams that the staff he hires can do as much work as possible in a shorter period of time. For average calculation of the efficiency of the work of the workforce performance indicators are used.

The most objective assessment will be the productivity of labor of workers performing homogeneous work under similar conditions. In this case, in the analysis, you can see how many operations, parts, assemblies are performed by employees, that is, calculate in physical terms: how much one person has produced products per hour, shift, month, or how much time he needs to manufacture a unit of production.

In production and execution various works their volume is calculated in terms of value, which to a certain extent reduces the accuracy of the calculation.

What is the practical meaning of these indicators?

- Comparison with the planned, base or actual indicator of previous periods helps to find out whether the efficiency of the work of the team as a whole and individual structures of the enterprise has increased or decreased.

- Allows you to assess the potential burden on employees and the ability of the enterprise to fulfill a certain volume of orders within a specified period.

- Contributes to the determination of the size of the usefulness of introducing additional technical means and application of new technologies. To do this, the average employee's output is compared before and after the introduction of technical innovations.

- Based on the analysis of the obtained data, a personnel incentive system is being developed. The amount of bonuses and incentives will be calculated correctly if it provides a corresponding increase in the company's revenue and profit.

- The analysis also reveals specific factors that positively and negatively affect labor intensity. For example, interruptions in the supply of spare parts, raw materials and materials, frequent breakdowns of equipment, insufficient organization of labor in the workshop or at the enterprise. If necessary, timekeeping of working hours is added to such an analysis and appropriate adjustments are made to the rationing of the work of individual departments and the work of middle and senior managers.

Detailed counting information this indicator you can watch the following video:

Formulas and calculation examples

The generalized formula for labor productivity:

P \u003d O / H, where

- P - average performance labor of one worker;

- O - the amount of work performed;

- H is the number of employees.

Such an indicator characterizing how much work one person performs for a selected period (hour, shift, week, month), is also called development.

Example 1 In January 2016, the fashion studio completed 120 tailoring orders outerwear(jackets). The work was done by 4 seamstresses. The productivity of one seamstress was 120/4 = 30 jackets per month.

Example 1 In January 2016, the fashion studio completed 120 tailoring orders outerwear(jackets). The work was done by 4 seamstresses. The productivity of one seamstress was 120/4 = 30 jackets per month.

Reverse indicator - laboriousness- determines how much labor (man-hours, man-days) is needed to produce a unit of output.

Example 2 In December 2015, the workshop of the furniture factory produced 2,500 chairs. According to the time sheet, the staff worked 8,000 man-hours. It took 8000/2500 = 3.2 man-hours to make one chair.

To determine the productivity of labor in the workshop, structural unit plant, factory for the period (month, quarter, year) the formula is used PT=оС/срР, where

- PT is the average labor productivity of one employee for the period;

- оС - the total total cost of finished products for the period;

- cp - shop workers.

Example 3 The shop of metal products in November 2015 produced finished products for a total amount of 38 million rubles. The average number of employees was 400 people. 63,600 man-hours worked. In December 2015, products worth 42 million rubles were manufactured, and the average headcount was 402 people. 73560 man-hours worked.

Example 3 The shop of metal products in November 2015 produced finished products for a total amount of 38 million rubles. The average number of employees was 400 people. 63,600 man-hours worked. In December 2015, products worth 42 million rubles were manufactured, and the average headcount was 402 people. 73560 man-hours worked.

Production per person:

- In November, it amounted to 38,000 thousand rubles / 400 = 95 thousand rubles.

- In December, 42,000 thousand rubles / 402 \u003d 104.5 thousand rubles.

The growth rate of labor productivity in the shop was 104.5 / 95 x 100% = 110%.

Labor intensity for the manufacture of finished products in the amount of 1 million:

- In November: 63600 man-hours / 38 million rubles = 1673.7 man-hours,

- In December: 73,560 man-hours / 42 million rubles = 1,751.4 man-hours.

Qualitative Analysis labor indicators makes it possible to optimize the total number of employees, their placement, identify existing shortcomings and reserves in the organization of labor and the need for technical improvement of work processes.

Efficient use of resources is a condition that ensures the fulfillment production plans. For the purpose of analysis, the organization's personnel is divided into production and administrative. Based on the name, it is clear that the first group includes workers directly engaged in the main activity of the enterprise, and the second - all the rest. For each of these groups, the average annual output is calculated and the quality of use is analyzed. work force.

Basic concepts

During the analysis of the labor force, She shows how many products are manufactured per hour (day, month, year). To calculate this indicator, you need to determine the average annual output and labor intensity. They best represent labor efficiency. Increasing productivity leads to increased production volumes and wage savings.

Resource availability

Of great importance is the number of employed people in the enterprise. When analyzing security, the actual number is compared with the planned and indicators for the previous period for each group of workers. A positive trend is one in which the average annual output grows against the background of a change (decrease) in the number of any of the groups of employed employees.

The reduction of auxiliary personnel is achieved by increasing the level of specialization of persons engaged in the adjustment and repair of equipment, the growth of mechanization and the improvement of labor.

The number of personnel is determined according to industry standards and rational use working time required to perform certain functions:

1. Workers: H \u003d Labor intensity: (Annual Fund of Working Time * Coefficient of Compliance with Standards).

2. Equipment workers: N = Number of units * Number of workers in this area * Load factor.

Skill level analysis

The number of employees by specialty is compared with the normative one. The analysis reveals a surplus (shortage) of workers in a particular profession.

The skill level score is calculated by summing tariff categories for each type of work. If the actual value turns out to be lower than planned, then this will indicate a decrease in product quality and the need to improve the skills of personnel. The opposite situation suggests that workers need to be paid extra pay for qualifications.

Managerial personnel are checked for compliance with the level of education of the position held. The qualification of an employee depends on age and experience. These parameters are also taken into account in the analysis. Calculates accepted and retired employees, including those for negative reasons. At the next stage, the use of working time is analyzed according to the following algorithm:

1. Nominal mode = 365 days - The number of weekends and holidays.

2. Private mode \u003d Nominal mode - The number of days of absence from work (vacation, illness, absenteeism, decision of the administration, etc.).

Labor intensity

Labor intensity is the time spent on the production of a unit of output:

Tr \u003d FRVi / FRVo, where:

- FRVi - time to create the final type of product;

- FRVo - the general fund of working hours.

The average annual output is the inverse indicator of labor intensity:

- T \u003d Time spent / Volume of production.

- T \u003d Number of personnel / Volume of production.

To calculate the productivity of one worker, in the above formula in the numerator you need to put one. The average annual output per worker is the inverse indicator of labor intensity. It not only displays the performance of a particular employee, but also makes it possible to draw up a plan for the next year.

With a decrease in labor intensity, labor productivity increases. This is achieved through the introduction of scientific and technical progress, mechanization, automation, revision, etc. Labor intensity should be analyzed not only with planned indicators, but also with other enterprises in the industry.

Output and labor intensity reflect results real work, on the basis of which it is possible to identify resources for development, increasing productivity, saving time, reducing the number.

performance index

This is another indicator of the performance of employees. It shows the rate of productivity growth.

ΔPT = [(B1 - B0) / B0] * 100% = [(T1 - T1) / T1] * 100%, where:

- B1 - average annual output of one employee in the reporting period;

- T1 - labor intensity;

- B0 is the average annual output of a worker in the base period;

- T0 - labor intensity of the base period;

As can be seen from the above formulas, the index can be calculated from the output and productivity data.

Changes in the index are determined based on the planned headcount savings:

ΔPT \u003d [E / (H - E)] * 100%, where E is the planned savings in numbers.

The index shows the change in performance in the base period compared to the previous one. Productivity depends on the competence of workers, availability necessary equipment, financial flows.

Alternative

P \u003d (Volume of production * (1 - Downtime ratio) / ( Labor costs* Number).

This approach does not take into account idle hours. The volume of production can be expressed in pieces, labor or monetary units.

Factor analysis

Since labor productivity is calculated based on the quantity of products manufactured per unit of time, it is these indicators that are subject to detailed analysis. In the course of calculations, the level of fulfillment of tasks, tension, increase in output, reserves for productivity growth and their use are determined.

Factors that affect labor productivity can be combined into groups related to:

Raising the technical level;

Improving the organization of work;

Increasing the qualifications of employees, the level of education of workers, strengthening discipline and improving the system of accrual and payment of wages.

Labor productivity is analyzed in the following areas:

- an assessment is made of the level of generalizing indicators;

- the factors influencing the average hourly output are analyzed;

- reserves for increasing productivity are identified;

- the labor intensity of products is studied.

Example 1

Based on the data presented in the table below, it is necessary to determine the average annual and average hourly output of the enterprise.

Indicator | Dynamics, % |

|||||

Plan for 2014 | Fact by 2014 | Fact / Plan |

||||

Manufacture of products, thousand rubles | ||||||

Worked by workers, thousand man-hours | ||||||

Labor intensity per thousand rubles. | ||||||

Average annual output, rub. | ||||||

Increase in productivity by reducing labor intensity:

According to the plan: (4.7 * 100) / (100-4.7) = 4.91%;

In fact: (9.03 * 100) / (100 - 9.03) = 9.92%.

The labor intensity plan was overfulfilled by 4.33%. As a result, the average annual output increased by 5.01%.

Peculiarities

- The number of employees in optimal conditions should be calculated according to the average. Each employee is counted once a day.

- Performance can be determined from revenue data from the income statement.

- Labor and time costs are also reflected in the accounting records.

Other indicators

The average productivity is determined if there are a large number of products with different labor intensity, according to the following formula:

Вср = ΣVolume of production of a type of product *Coefficient of labor intensity of a type of product.

The value (K i) for positions with minimal labor intensity is equal to one. For other types of products, this indicator is calculated by dividing the labor intensity of a particular product by the minimum.

Labor productivity per worker:

Pr \u003d (Volume of output * (1 - K i) / T.

Pr \u003d (p. 2130 * (1 - K)) / (T * H).

Productivity must be constantly increased through the use of new equipment, training of workers, and organization of production.

Payroll fund (FZP)

The analysis of the wage bill begins with the calculation of the deviations of the actual (FZPf) and planned (FZPp) salaries:

FZPa (rub) \u003d FZPf - FZPp.

The relative deviation takes into account the implementation of the production plan. To calculate it, the variable part of the salary is multiplied by the plan performance factor, while the constant part remains unchanged. Piecework wages, bonuses for production results, vacation pay and other payments that depend on production volumes are included in the variable part. The salaries calculated according to tariffs refer to the permanent part. Relative deviation of FZP:

FZP \u003d FZP f - (FZPper * K + ZP constant).

- production volume (O);

- production structure (C);

- specific labor intensity of products (UT);

- salary for one man-hour (FROM).

FZP lane \u003d O * C * UT * FROM.

Before analyzing each of the factors, it is necessary to carry out intermediate calculations. Namely: define the FZP variable:

- according to the plan: FZP pl \u003d O * C * FROM;

- according to the plan, taking into account the given volume of production: wage bill cond. 1 = FZP pl * K;

- according to the plan calculated with the actual volume of production and structure: wage bill cond. 2 \u003d O * UT * FROM;

- actual with specific labor intensity and a given level of remuneration: wage bill cond. 3 \u003d Of * Utf * OTf.

Then you need to multiply each of the obtained values by the absolute and relative deviation. So you can determine the influence of each of the factors on the variable part of the salary.

The constant part of the wage bill is affected by:

- number of personnel (H);

- number of days worked per year (K);

- average shift duration (t);

- average hourly wage (HWP).

FZP f \u003d H * K * t * NZP.

The influence of each of the factors on the final result can be determined in exactly the same way. First, changes in each of the four indicators are calculated, and then the obtained values are multiplied with absolute and relative deviations.

The next stage of the analysis is the calculation of the effectiveness of the use of payroll. For expanded reproduction, profit, profitability, it is necessary that the growth of productivity outpaces the growth of the wage bill. If this condition is not met, then there is an increase in cost and a decrease in profit:

- earnings (J RFP) \u003d Average salary for the reporting period / Average salary for the planning period;

- average annual output (J Fri) = Output for the reporting period / Output for the planning period;

- labor productivity: (K op) / K op \u003d J pt / J zp;

- FZP savings: E \u003d FZPf * ((J zp - J pt) / J zp).

Example 2

- production volume - 20 million rubles;

- average annual number - 1,200 people;

- for the year, the employees of the organization worked 1.72 million people per hour and 0.34 million people per day.

- Hourly output per worker \u003d Volume of production / Man-hours worked \u003d 20 / 1.72 \u003d 11.63 rubles.

- Daily output \u003d 20 / 0.34 \u003d 58.82 rubles.

- Annual output \u003d 20 / 1.2 \u003d 16.66 rubles.

Popular

- Program for changing the angle of attack and pitch

- Actual output speed Calculation of closed gear train

- What is the procedure for the use of official transport by an employee

- aircraft fuel system

- Agreement for the evacuation of a vehicle Standard agreement for the evacuation of a vehicle

- Bulldozer performance and how to improve it Basic information about bulldozers

- Toyota Production System (TPS) and Lean Manufacturing

- Examination tickets by profession line pipe fitter

- What to do if you don't feel like doing anything

- Globus - shops for the whole family