Verification of purchased products organization and control methods. Verification of purchased products organization and methods of control GOST 24297 verification of purchased products

Put into effect by order of the Federal Agency for Technical Regulation and Metrology dated August 26, 2013 N 544-st

Interstate standard GOST 24297-2013

"VERIFICATION OF PURCHASED PRODUCTS. ORGANIZATION AND CONTROL METHODS"

Verification of purchased products. Organization and methods of control

Instead of GOST 24297-87

1 area of use

This standard establishes the basic requirements for the organization, procedure for conducting and formalizing the results of verification of purchased products coming from the supplier to the consumer.

2 Normative references

GOST 8.009-84 State system ensuring the uniformity of measurements. Normalized metrological characteristics of measuring instruments

GOST ISO 9000-2011 Quality management systems. Fundamentals and vocabulary

GOST ISO 9001-2011 Quality management systems. Requirements

GOST 15467-79 Product quality management. Basic concepts. Terms and Definitions

GOST 16504-81 State product testing system. Testing and quality control of products. Basic terms and definitions

GOST 18321-73 Statistical quality control. Methods for random selection of samples of piece products

NOTE When using this standard, it is advisable to check the validity of the referenced standards in information system general use - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet or according to the annual information index " National Standards", which is published as of January 1 of the current year, and on issues of the monthly information index "National Standards" for the current year. If the reference standard is replaced (modified), then when using this standard, you should be guided by the replacing (modified) standard. canceled without replacement, the provision in which the link to it is given applies to the extent that this link is not affected.

3 Terms and definitions

This standard uses terms and definitions in accordance with GOST ISO 9000, GOST 15467 (with the exception of terms defined in GOST ISO 9000) and GOST 16504.

4 Symbols and abbreviations

GOST - interstate standard;

ND - normative documents;

SI - measuring instruments.

5 General provisions

5.1 Verification of the purchased products is carried out in order to verify the compliance of the product quality with the established requirements and to prevent the launch of non-conforming products into production or operation.

5.2 Verification of the purchased products is carried out by the personnel responsible for its implementation and having the appropriate authority.

If necessary, specialists from third-party organizations can be involved in product verification on a contractual basis with the definition of the conditions and obligations of the parties for product verification.

Departments and organizations that receive products for inspection or testing must perform them in deadlines and draw up a conclusion on the establishment of the fact of compliance or non-compliance of the quality of the purchased products with the established requirements.

5.3 Verification of purchased products is carried out in accordance with the list of products subject to verification approved by the consumer organization.

5.4 The range of purchased products subject to verification, controlled parameters and properties, type of control and its scope should be determined based on the stability of the quality of suppliers' products, the effectiveness of their quality management systems, and the importance of this parameter.

5.5 Lists of products subject to verification should contain:

Name, brand and type of purchased products;

Designation of ND, the requirements of which the products must comply with;

Controlled properties, parameters and points of their control;

Type of control, methods of control, volume of samples (samples or samples), control standards and decision rules.

NOTE Decision rules are those that allow a solution to be found without any consideration of different options. The peculiarity of decision rules is that the sequence of actions is determined by applying simple procedures on the initial data;

Measuring or testing instruments or their specifications;

Instructions on marking (branding) of products based on the results of verification;

Permissible resource consumption during verification.

If necessary, the lists may include requirements or instructions that reflect the features of a particular product.

5.6 Sections of the list of purchased products subject to verification are developed by:

Design services - for products intended for assembly;

Technological services - for raw materials, materials and semi-finished products intended for production, repair, operation and maintenance.

5.7 The lists of products subject to verification are agreed with the person responsible for product verification and metrology (if necessary, with the customer, if this is stipulated in contracts or supply contracts).

5.8 The lists of products subject to verification are approved by an authorized person of the consumer organization.

If necessary, verification of purchased products that are not included in the list can be carried out.

5.9 Verification of purchased products, depending on their volume, can be carried out by complete or selective control or testing. Each of these types of control (tests), depending on the means of obtaining information, its reliability and sufficiency, may include measuring, visual and organoleptic verification methods.

5.9.1 Measuring methods verification should be used in cases where increased reliability of the information received is required and when the means of monitoring and testing products are any measuring instruments and test equipment.

5.9.2 Organoleptic and visual verification methods should be used in cases where the means of control, testing or measurement of products, as a rule, are the sense organs, for example: organoleptic - smell, taste; visual - color, marking, packaging, completeness.

5.9.3 When carrying out complete verification, each item in the purchased lot should be subjected to control or testing in order to identify non-conforming items of product and decide on the suitability of the product for use.

End-to-end verification should be carried out in cases where it is technically possible and economically feasible.

5.9.4 During selective verification of purchased products from a batch of products, samples (samples or samples) are randomly selected, based on the results of control or testing of which a decision is made on the suitability of products for use.

Control or test plans, as well as acceptance rules, must comply with the requirements established in the RD for this type of product, and must be focused on the use of statistical methods.

Rules for the selection of product units in the sample - according to GOST 18321.

5.10 When re-submitting a purchased batch of products for verification, it should be indicated that the batch previously recognized as non-conforming is submitted for verification again, so that the person responsible for verification pays special attention to the characteristics due to which it was recognized as non-conforming.

5.11 If necessary, the consumer may conduct additional product checks not provided for in the RD. The scope and methods of verification in this case must be agreed between the supplier and the consumer.

5.12 During verification, if necessary, it is allowed to test components in the conditions and modes provided for by the RD, while the list of products subject to verification should contain appropriate instructions.

5.13 The decision on the need to introduce, tighten, weaken or cancel the verification of purchased products is made by the consumer based on the features, nature and purpose of the product or the results of verification of this or similar products for the past period of time, or the results of use finished products at the consumer.

6 Organization of verification of purchased products

6.1 The main tasks of the personnel performing product verification are:

Verification of purchased products, as well as execution of documents and records based on the results of verification;

Checking the availability of accompanying documentation for products, certifying its quality and completeness;

Timely issuance of permits for launching products into production based on the results of verification;

Periodic control over compliance by warehouse workers with the rules for storing and issuing products to production;

Informing departments about the quality of purchased products;

Notification of suppliers about the shortcomings and inconsistencies of products identified during verification, in the process of production and operation; calling, if necessary, representatives of suppliers to participate in the acceptance and preparation of acts on non-conformity of products;

Accumulation of statistical data on the level (dynamics) of the quality of products received from suppliers.

6.2 Verification of purchased products should be carried out in a specially designated place equipped with all necessary measuring, control and testing equipment, provided with measurement, control or testing methods for products, as well as the necessary RD for products.

6.3 The conditions under which verification should be performed should be specified.

Such conditions or requirements should include, for example, the requirements for unpacking and preservation of products, the time for the products to enter the operating mode, the elimination of solar radiation, and aggressive environments.

6.4 The sequence of verification should be such that the control or testing of some parameters or properties of the product does not lead to a change in others, as well as hidden defects, if possible, were discovered at the verification stage, and not during production or operation.

6.5 The products are subjected to verification according to the rules and to the extent established in the list or RD for a particular type of product.

6.6 If necessary, verification of products can be carried out in the presence of a representative of the supplier or a third party (if it is stipulated in contracts or supply contracts).

6.7 Products for verification are submitted with accompanying documentation certifying its quality (for example, a certificate, passport, quality certificate, etc.).

6.8 Methods and means of control and testing used in the verification of purchased products should be selected taking into account the requirements for the accuracy of measuring the parameters or properties of products established in the RD for a specific type, as well as in GOST 8.009.

If the measuring instruments and control methods differ from those specified in the RD, then the consumer must agree on the technical characteristics of the measuring instruments used and control methods with the supplier.

If during verification it is found that the measuring equipment does not meet the established requirements, then verification using this equipment should be stopped. Products, during the verification of which these nonconformities were found, should be re-verified using other operable and timely verified means, and based on the results of the re-verification, a decision is made on further actions.

6.9 For verification, the products accepted by the authorized person of the supplier are submitted, together with the accompanying documentation certifying its quality (certificate, passport, quality certificate, etc.), drawn up in the prescribed manner.

7 Procedure for verification of purchased products

7.1 Products received for verification must be stored separately from those previously accepted or recognized as non-conforming based on the results of verification and have an appropriate identification (label, tag, etc.) indicating that the product has not yet been accepted or is under control or testing.

7.2 Verification of purchased products can be carried out at any time from the moment it arrives at the consumer's warehouse and before it is put into production. However, this should take into account the timing of claims, if it is subsequently found that the purchased products do not meet the established requirements.

7.3 Upon receipt for verification of products without accompanying documentation certifying its quality, in individual cases verification can be carried out for compliance with the current ND for this type of product with the obligatory execution of an act on its actual quality and completeness, indicating the missing documents.

7.4 Before submitting products for verification, if these products are not subjected to verification prior to storage, they must be placed on special sites or in warehouses separately by receipts, batches, brands, names, sizes. When unloading products, the requirements and rules established in technological maps, methods, diagrams and instructions.

7.5 Verification of products according to parameters or properties that are not specified in the RD, contracts or supply contracts may be carried out without agreement with the supplier and without the right to make claims on them to the supplier (for example, to develop the production technology of products).

7.6 Unpacking of products, their sorting, delivery to the place of verification, stacking, marking after verification is carried out by the personnel responsible for its storage.

7.7 The personnel responsible for storage must timely submit the purchased products for verification along with the supplier's accompanying documentation certifying its quality and completeness.

7.8 Personnel responsible for product verification should verify:

Completeness and quality of the accompanying documentation certifying the quality of products (certificate, passport, certificate of quality, etc.), with registration in the verification log (Appendix A);

Appearance of products, surface condition, packaging, labeling, presence of mechanical and other damage.

The personnel responsible for verification must also carry out the necessary measurements of the parameters or properties of the product and issue a sampling report (samples or samples) (Appendix B).

7.9 Selection of samples (samples or samples) of products received for verification is carried out by the personnel responsible for its storage, under the control of the personnel responsible for verification, from each incoming batch separately in the volumes specified in the list of products subject to verification, or RD for a specific product type.

7.10 The batch of product from which the samples (samples or samples) are taken and the samples themselves (samples or samples) must be identified.

8 Registration of results of verification of purchased products

8.1 The personnel responsible for verification, upon receipt of products and applications for verification, must register it in the verification log (see Appendix A) indicating the name, quantity, date of receipt, supplier, etc., followed by the results of the control, tests or measurements of controlled properties or parameters of products, as well as the execution of a sampling report (sample or sample) (see Appendix B).

8.2 If the product conforms to the established requirements, the personnel responsible for verification must decide whether to transfer it to production.

On accepted products, the warehouse staff should issue a conformity label (Appendix B), signed by the personnel responsible for verification, if possible and appropriate.

8.3 Nonconforming product shall be identified with a label of nonconformity (Appendix D) and placed in isolation to prevent inadvertent use or delivery of such product until the supplier decides on further action if the product is not immediately returned to the supplier.

A claim or complaint must be filed for non-conforming products, which are issued to the supplier along with a safe receipt (Appendix D) and an act of sampling (sampling or sampling) (see Appendix B).

8.4 For products found to be nonconforming, the personnel responsible for verification shall issue a prohibition (Annex E) from release into production.

Annex A

(reference)

Purchased Products Verification Log Form

Purchased Products Verification Log

Annex B

(reference)

Form of act of sampling (sampling or samples)

The act of sampling (sampling or sampling)

This act indicates that on ____ ___________, samples (samples or samples) were taken for control or testing and sealed.

1 Names and positions of members of the commission ________________________________

2 Name of product ___________________________________________

3 Supplier _____________________________________________________________

4 Railway (or other) waybill ____________ account N _____________

5 Car (car) N ______ __________________

6 Date of receipt of products at the warehouse _____ ______

7 Quantity (weight), kg ______________________________________________

8 Type of packaging _____________________________________________________

9 Numbers of places from which samples were taken (samples or samples) __________

10 Samples (samples or samples) are selected in accordance with _______________

11 Sampling method (samples or samples), number ________________

12 Samples (samples or samples) are selected for storage, sealed and provided with labels (tags) __________________________________________________________

__________________________________________________________________

13 Selected samples (samples or samples) were sent for control or testing to ________________________________________________

_________________________________________________________________

Surnames and signatures of the commission members: _______________________

_______________________

Annex B

(reference)

Compliance label form

Compliance Label

5 Products comply with _________________________________________

Surname and signature of the person,

Responsible for verification ____________________________

Annex D

(reference)

Form of non-compliance label

Non-compliance label

1 Product name __________________________________________

2 Batch number __________________________________________________________

3 Quantity (pieces, kg, m) _______________________________________________

4 Date of admission to the organization __________________________________

5 Number of the act of sampling (sample or sample) __________________

6 Products do not comply with ______________________________________

Specify the document that establishes the requirements

Surname and signature of the person responsible for verification ____________

Date ______ __________________________

Annex D

(reference)

Receipt Form

Safety receipt

Products ___________________ that do not comply with the act _________

Act number

dated ____ ___________, taken _________________ for safekeeping

Name of company

from ____ ___________ to ____ ___________

Head warehouse __________________/____________/

Specify the document that establishes the requirements

Appendix E

(reference)

Prohibition form

Prohibition

Issued by __________________________________________________________________

To whom

in that it is forbidden to launch products _______________

Name

________________________________________________________________________,

Products

does not meet the requirements of __________________________________________

Specify the document that establishes the requirements

The supplier _______________________________________________________________

_________________________________________________________________________

Date of admission ____ ______________

Accompanying documents ______________________________________________

Surname and signature of the person,

person responsible for verification _________________________

Date _____ ___________________

page 1

page 2

page 3

page 4

page 5

page 6

page 7

page 8

INPUT CONTROL OF PRODUCTS

MAIN PROVISIONS

Introduction date 01.01.88

This standard establishes the basic provisions for organizing, conducting and formalizing the results of incoming inspection of raw materials, materials, semi-finished products and components (hereinafter referred to as products) used for the development, production, operation and repair of industrial products.

1. GENERAL PROVISIONS

1.1. The terms used in this standard are according to GOST 16504 and GOST 15895 *.

*In the territory Russian Federation valid GOST R 50779.10-2000 and GOST R 50779.11-2000.

1.2. Input control is carried out at enterprises (associations) and organizations that develop and manufacture industrial products and those who carry out repairs.

1.3. Input control is carried out in order to prevent the launch into production of products that do not meet the requirements of design and regulatory and technical Documentation, supply contracts and permit protocols in accordance with GOST 2.124 (hereinafter referred to as the established requirements).

1.4. Input control is carried out according to the parameters (requirements) and methods established in the NTD for controlled products, contracts for its supply and authorization protocols.

1.5. The product range, controlled parameters (requirements), the type of control and the sample or sample size are determined based on the stability of the quality of the suppliers' products, the degree of development of new types of products, the importance of this parameter (requirement) for the functioning of the manufactured products, and are set in the list of products subject to input control.

1.6. The sections of the list are developing:

1) design services of the enterprise for products intended for assembly;

2) technological services enterprises - for raw materials, materials and semi-finished products.

1.7. The lists of products subject to incoming control are coordinated with the technical control department (QCD), the metrological service, as well as with the State acceptance and (or) representative office of the customer ** and approve:

1) the chief designer of the enterprise-developer - in the development of prototypes of products;

2) the chief engineer of the consumer enterprise - during production and repair.

1.8. The list of products subject to incoming control must contain:

1) name, brand (drawing number) and type of controlled products;

2) designation of the NTD, the requirements of which the products must comply with (details of the supply contract or the permit protocol);

3) controlled parameters (requirements) or clauses of the NTD (agreement, permit protocol) in which they are established;

4) type of control, sample or sample size, control standards, permitting rules;

5) measuring instruments or their technical characteristics;

6) warranty period;

7) instructions on marking (branding) of products based on the results of incoming control;

8) allowable resource consumption during input control (resource consumption should be minimal).

If necessary, the list may include requirements or instructions reflecting the features of the product.

1.9. The input control of products is set to continuous or selective. When establishing selective control, control plans and acceptance rules must comply with those established in the technical documentation for products.

Note. For electrical radio products with the index “OS”, complete input control is required.

1.10. If necessary, the consumer can conduct additional product checks that are not provided for by the established requirements. The scope and methods of checks are agreed between the consumer and the supplier, as well as with the State Acceptance and (or) the representative office of the customer.

During the input control, it is allowed to train components in the conditions and modes provided for by the NTD, while the list of products subject to input control should contain appropriate instructions.

1.11. Technological documentation for the input control processes according to R 50-609-40 is developed by the technological services of the enterprise in agreement with the Quality Control Department, as well as with the State Acceptance and (or) representative office of the customer and approves Chief Engineer enterprises.

1.12. The decision to tighten, weaken or cancel the input control is made by the consumer in agreement with the State Acceptance and the representative office of the customer based on the results of the input control for the previous period or the results of operation (consumption) of products.

2. ORGANIZATION OF INPUT CONTROL

2.1. Input control is carried out by the input control unit, which is part of the technical control service of the enterprise (association).

2.2. The main tasks of incoming control are:

1) checking the availability of accompanying documentation for products, certifying the quality and completeness of products;

2) control of compliance of the quality and completeness of products with the requirements of design and regulatory and technical documentation and its application in accordance with the permit protocols;

3) the accumulation of statistical data on the actual level of quality of the products obtained and the development on this basis of proposals for improving the quality and, if necessary, revising the requirements of scientific and technical documentation for products;

4) periodic monitoring of compliance with the rules and terms of storage of products of suppliers.

2.3. Input control must be carried out in a specially designated room (section), equipped with the necessary means of control, testing and office equipment, as well as meeting the requirements of labor safety.

Workplaces and personnel performing incoming control must be certified in the prescribed manner.

Measuring instruments and test equipment used in the input control are selected in accordance with the requirements of the NTD for controlled products and GOST 8.002 *. If the metrological means and methods of control differ from those specified in the NTD, then the consumer agrees on the technical characteristics of the means used and methods of control with the supplier, the State Acceptance and (or) with the representative office of the customer.

* PR 50.2.002-94 is in force on the territory of the Russian Federation

To carry out tests, checks and analyzes related to incoming control, products can be transferred to other divisions of the enterprise (laboratories, control and testing stations, etc.).

3. PROCEDURE FOR INPUT CONTROL

3.1. Products accepted by the Quality Control Department, the representative office of the customer, the State Acceptance Committee of the supplier enterprise and received with the accompanying documentation drawn up in the prescribed manner are allowed for incoming inspection.

3.2. When conducting input control, it is necessary:

1) check the accompanying documents certifying the quality of the products and register the products in the registers of the results of the input control (Appendix 1);

2) control the selection of samples or samples by warehouse workers, check the completeness, packaging, labeling, appearance and complete a sampling or sampling report;

3) conduct product quality control according to technological process input control or transfer samples or samples for testing (analysis) to the appropriate department.

3.3. The department that received samples or samples for testing (analysis) conducts tests within the established time limits and issues a conclusion to the input control department on the compliance of the tested samples or samples with the established requirements.

3.4. The results of tests or analyzes (physical and mechanical properties, chemical composition, structure, etc.) must be transferred to production along with the tested products.

3.5. Products accepted based on the results of incoming inspection with a corresponding mark in the accounting or accompanying documents should be transferred to production.

Marking (branding) of accepted products is allowed.

3.6. Products received from the supplier before the input control must be stored separately from those accepted and rejected by the input control.

3.7. Products rejected during incoming inspection must be marked “Rejected” and sent to the reject isolator.

4. REGISTRATION OF THE RESULTS OF THE INPUT CONTROL

4.1. Based on the results of the input control, a conclusion is drawn up on the conformity of the products with the established requirements and a register of the results of the input control is filled out.

4.2. In the accompanying documents for the products, a note is made about the input control and its results, the products are marked (branded), if this is provided for by the list of products subject to input control.

4.3. If the products meet the established requirements, the incoming control division makes a decision to transfer it to production.

If non-compliance with the established requirements is detected during the input control, the products are rejected and returned to the supplier with a claim.

In case of repeated receipt of low-quality products or receipt of them in large quantities, the consumer reports this to the territorial body of the Prosecutor's Office at the location of the supplier.

4.4. Based on the results of the input control, the consumer, if necessary, informs the supplier's ministry, the customer's representative office and (or) the State acceptance body at the supplier enterprise, and in the absence of the latter, the territorial body of the State Standard at the location of the supplier to take measures in accordance with the requirements imposed on them with functions (app. 2).

4.5. For electrical and radio products accepted by the customer's representative office, information is sent to the customer's head institute for these products (Appendix 3).

APPENDIX 2

|

1. Name of the Gospriemka body, representative office of the customer and the territorial body of Gosstandart and its postal address ___________________________________________________________________________ 2. Name of the consumer enterprise _____________________________________ conditional ___________________________________________________________________________ Name 3. Name of the ministry ________________________________________________ according to ___________________________________________________________________________ departmental subordination of the enterprise INTELLIGENCE on the supply of raw materials, materials, semi-finished products and components in violation of the requirements of NTD (TU standards) for the period from ________ to ______ Note. If the materials and components are accepted by the State Acceptance Committee or the representative office of the customer, this is indicated in the note. |

APPENDIX 3

obligatory

FORM OF PRESENTATION OF INFORMATION

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the USSR State Committee for Standards

This document was recognized automatically. In the block on the right you can find a scanned copy. We are working on manual recognition of documents, but this is a titanic work and it takes a lot of time. If you want to help us and speed up the processing of documents, you can always do this by donating a small amount of money to us.

GOST 190618-80

INTERSTATE STANDARD

GENERAL SPECIFICATIONS

Official edition

GOST 190618-80

INTERSTATE STANDARD

SELF-TAPPING SCREWS FOR METAL AND PLASTIC

GENERAL SPECIFICATIONS

Official edition

Grushpa G32

INTERSTATE STANDARD

Introduction date 01.01.82

1. DIMENSIONS

Grushpa G32

INTERSTATE STANDARD

SELF-TAPPING SCREWS FOR METAL AND PLASTIC GOST General specifications 10618-80

Self-tapping screws for metals and specifications

Introduction date 01.01.82

This International Standard applies to self-tapping screws for metal and plastics, grade B, with blunt pointed ends.

The requirements of this standard are mandatory.

(Revised edition, Rev. No. 2).

1. DIMENSIONS

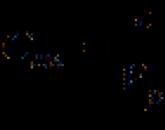

1.1. In terms of shape and dimensions, self-tapping screws must comply with the standards for the design and dimensions of specific types of screws. 1.2. The dimensions of the thread and the end of the screw must correspond to those indicated in Fig. 1, 2 iv

Coarse pitch thread Conn variant

Official publication Reprint prohibited *

S. 2 GOST 10618-80

Table 1

Thread pitch R 1.25 1.75 2.00 2.50 3.50 Platform width d, max | oto 0.15 0.20 Length of conical end /, > 2.9 4.3 5.7 6.1

Thread with fine pitch

S. 2 GOST 10618-80

Table 1

Diameter | VV thread nom 4 | Previous recoil. ov | 01s | ote=0.22

Internal thread diameter 4\. not 1.7 2.1 3.5 4.2 5.6 more

Thread pitch R 1.25 1.75 2.00 2.50 3.50 Platform width d, max | oto 0.15 0.20 Length of conical end /, > 2.9 4.3 5.7 6.1

Note. Depending on the method of thread formation, the edges of the platform A may have fillets,

Thread with fine pitch

Dnamer | Home | [in [in thread 4 | Previous off pov | ohm | 0.18 =0.22

Internal thread a,. 2.0 2.3 2.9 3.9 6.2 no more

Thread pitch A ooo 1 No. Platform width 5, no more | oo 0.15

Tapered end length with 5.0 angle | 60 | 7.0 41 =

Length of tapered end with angle 1.00 1.50 1.75 2.00 7° 30" i, =

(Changed edition, Rev. No. 1, 2). 1.3. The scheme for constructing a symbol for self-tapping screws is indicated in Appendix 1.

GOST 10618-80 S. 3

2. TECHNICAL REQUIREMENTS

Table 3

30X GSA according to GOST 4543 12

(Revised edition, Rev. No. 2).

(Revised edition, Rev. No. 2).

3. ACCEPTANCE RULES

GOST 10618-80 S. 3

2. TECHNICAL REQUIREMENTS

2.1. Limit deviations of dimensions and arrangement of surfaces, surface roughness of self-tapping screws must comply with the standards for the design and dimensions of specific screw forks.

2.2. Grades of materials and their symbols must correspond to those indicated in Table. 3.

Table 3

Symbol of the brand Name of the material Brand of the material material (group)

Carbon steels 08kp, 10. 10kp according to GOST 10702 ol 20, 20kp, 25 according to GOST 190702 04 Alloy steels 20X. 40X according to GOST 4543 10

30X GSA according to GOST 4543 12

(Revised edition, Rev. No. 2).

2.3. It is allowed to use for the manufacture of screws not listed in Table. 3 grades of materials, the mechanical properties of which are not lower than the properties of the grades of materials established in Table. 3.

In this case, in the designation of the screw, instead of the symbol of the materials, its brand is indicated.

2.4. Self-tapping screws must be subjected to thermal or chemical-thermal treatment.

The hardness of screws with a large thread pitch should be 57 ... 63 NKS. with small - 37 ... 47 ". The surface hardness of screws after chemical-thermal treatment must be at least 450 83NV15M. The depth of the chemical-thermal treatment layer should be: for diameters from 2 to 3 - 0.04-0.1 mm; ° » 4» 6 - 0.05-0.18 mm: » » » 7 - 0.1-0.23 mm.

(Changed reaction, Rev. No. 1, 2).

2.5. Steps angle of the thread profile, angles of the conical part of the rod must be ensured by the accuracy of the manufacture of tools or copiers, for which the allowable deviation from the nominal value should not exceed + 10%.

2.6. Reducing the outer diameter of the screw within the tolerance field can only be towards the end of the screw.

2.7. Self-tapping screws with a pointed end must have a cylindrical shank with a full-profile thread up to a cone.

2.8. For screws having less than four threads, the length of the conical end shall not exceed 30% of the total length of the screw.

(Revised edition, Rev. No. 2).

2.9. The thread must be clean and free of nicks and burrs. Partial undercuts, thickenings or tears of turns are not allowed.

2.19. Coating forks and their symbol - according to GOST 1759.0.

(Revised edition, Rev. No. 2).

2.11. Tolerances for dimensions, shape and location of screw surfaces - according to GOST 1759.1.

Permissible defects in the surface of screws - according to GOST 1759.2.

2.12. On screws with a pointed end, the blunting of the tip of the gimlet by more than 15% of the thread diameter is not allowed.

2.11, 2.12. (Introduced additionally, Amendment No. 2).

3. ACCEPTANCE RULES

3.1. Screw acceptance rules - according to GOST 17769.

S. 4 GOST 10618-80

4. CONTROL METHODS

5 for screws: coarse pitch

threads 2.5 3.0 4.0 5.0 8.0

S. 4 GOST 10618-80

4. CONTROL METHODS

4.1. Visual inspection of screws, checking dimensions, surface roughness, surface defects. hardness, coating thickness and measurement of the depth of the decarburized layer - according to GOST 1759.0, GOST 1759.2.

4.2. Screws are checked for screwing in at the request of the consumer by the following method:

the screws are screwed into the test steel plate:

the hardness of the steel test plate is 125 ... 165 HB, the carbon content in the steel of the plate should be no more than 0.23%:

plate thickness 5. as well as the diameters of the holes must correspond to those indicated in Fig. Zee in the table. 4.

The end of the screw must protrude from the plate by at least two turns of the full thread profile. Screws having less than four threads are driven into the plate with a gap between the head and the plate. no more than the allowable dissatisfaction of the thread.

After unscrewing, there should be no chipping, cracks, broken or crumpled threads on the turns, and no crushing of the bearing surfaces of the spline on the head.

Table 4 mm nominal diameter 3 5 x thread d

5 for screws: coarse pitch

threads 1.25 1.25 1.75 2.50 3.50 with fine pitch

threads 2.5 3.0 4.0 5.0 8.0

d; (H13) aaa coarse thread 2.0 3.8 4.8 6.0

fine pitch 2.1 2.5 3.5 4.5 5.5 7.5

4.1, 4.2. (Modified Reaction, Rev. No. 1) 5. PACKAGING AND LABELING

5.1. Package. marking, transportation and storage - in accordance with GOST 18160. (Changed edition, Amendment No. 2).

GOST 10618-80 S. 5

APPENDIX 1 Mandatory

liamster |,

designation

Coating thickness

cover fork

Rated fine thread pitch

Screw length

INFORMATION DATA

4. REPLACE GOST 190618-63

GOST 18160-72 5.

GOST 10618-80 S. 5

APPENDIX 1 Mandatory

SCREW FOR CONSTRUCTION OF SCREW SYMBOLS

liamster |,

designation

Name Version Material group Condition

Coating thickness

cover fork

Rated fine thread pitch

Screw length

Designation of the corresponding standard for dimensions

Note. Execution |. large thread pitch and lack of coating are not indicated in the symbol.

An example of a symbol for a screw in version 2. with a thread diameter & = $ mm, with a fine thread pitch, length / = 30 mm. carbon steel with 6 µm ink coating, passivated:

APPENDIX 1. (Changed edition. Amendment No. 1).

APPENDIX 2. (Deleted, Rev. No. |).

INFORMATION DATA

1. DEVELOPED AND INTRODUCED by the Ministry of Automobile and Agricultural Engineering of the USSR

2. APPROVED AND INTRODUCED BY Decree of the USSR State Committee for Standards No. 6109 dated December 30, 1980

3. The standard complies with international standards ISO 1478-83 in terms of thread diameter tolerances and ISO 2702-74 in terms of surface hardness and screw control methods.

4. REPLACE GOST 190618-63

5. REFERENCE REGULATIONS AND TECHNICAL DOCUMENTS

GOST 1759.0-87 2.10, 4.1 GOST 1759.1-82 2.11 GOST 1759.2-82 2.11. 4.1 GOST 45$43-71 2.2 GOST 10702-78 2.2 GOST 17769-83 3.1

GOST 18160-72 5.

6. EDITION with Amendments No. 1, 2, approved in April 1985, March 1991 (IUS 7-85, 6-91)

GOST 24297-2013

GOST 24297-2013

6.7 Products for verification are submitted with accompanying documentation certifying its quality (for example, a certificate, passport, quality certificate, etc.).

6.8 Methods and means of control and testing used in the verification of purchased products should be selected taking into account the requirements for the accuracy of measuring the parameters or properties of products established in the RD for a specific type, as well as in GOST 8.009.

If the measuring instruments and control methods differ from those specified in the RD, then the consumer must agree on the technical characteristics of the measuring instruments used and control methods with the supplier.

If during verification it is found that the measuring equipment does not meet the established requirements, then verification using this equipment should be stopped. Products, during the verification of which these nonconformities were found, should be re-verified using other operable and timely verified means, and based on the results of the re-verification, a decision is made on further actions.

6.9 For verification, the products accepted by the authorized person of the supplier are submitted, together with the accompanying documentation certifying its quality (certificate, passport, quality certificate, etc.), drawn up in the prescribed manner.

7 Procedure for verification of purchased products

7.1 Products received for verification must be stored separately from those previously accepted or recognized as non-conforming based on the results of verification and have an appropriate identification (label, label, etc.) indicating that the product has not yet been accepted or is under control or testing.

7.2 Verification of purchased products can be carried out at any time from the moment it arrives at the consumer's warehouse and before it is put into production. However, this should take into account the timing of claims, if it is subsequently found that the purchased products do not meet the established requirements.

7.3 When products are submitted for verification without accompanying documentation certifying their quality, in some cases verification can be carried out for compliance with the current RD for this type of product with the obligatory execution of an act on its actual quality and completeness, indicating the missing documents.

7.4 Before submitting products for verification, if these products are not subjected to verification prior to storage, they must be placed on special sites or in warehouses separately by receipts, batches, brands, names, sizes. When unloading products, the requirements and rules established in technological maps, methods, diagrams and instructions must be observed.

7.5 Verification of products according to parameters or properties that are not specified in the RD, contracts or supply contracts may be carried out without agreement with the supplier and without the right to make claims on them to the supplier (for example, to develop the production technology of products).

7.6 Unpacking of products, their sorting, delivery to the place of verification, stacking, marking after verification is carried out by the personnel responsible for its storage.

7.7 The personnel responsible for storage must timely submit the purchased products for verification along with the supplier's accompanying documentation certifying its quality and completeness.

7.8 Personnel responsible for product verification should verify:

Completeness and quality of the accompanying documentation certifying the quality of products (certificate, passport, certificate of quality, etc.), with registration in the verification log (Appendix A);

Appearance of products, surface condition, packaging, labeling, presence of mechanical and other damage.

Staff. the person responsible for verification must also carry out the necessary measurements of the parameters or properties of the product and draw up a sampling report (samples or samples) (Appendix B).

7.9 Selection of samples (samples or samples) of products received for verification is carried out by the personnel responsible for its storage, under the control of the personnel responsible for verification, from each incoming batch separately in the volumes specified in the list of products subject to verification, or RD for a specific product type.

7.10 The batch of product from which the samples (samples or samples) are taken and the samples themselves (samples or samples) must be identified.

GOST 24297-2013

GOST 24297-2013

8 Registration of results of verification of purchased products

GOST 24297-2013

Annex A (informative)

cat, etc.) verification

le le le le Je lr lee Je]wm

GOST 24297-2013

Annex A (informative)

Purchased Products Verification Log Form

Purchased Products Verification Log

Certificate "Conclusion on the Place Number of fiqat quality, Date NameMass, Date of selection of the wagon quality podli person, act" batch, | ready" | sample is responsible"

(automa» (nacnopr, 6 shimy) production of certifinemer singing

cat, etc.) verification

le le le le Je lr lee Je]wm

GOST 24297-2013

Annex B (informative)

product name

The supplier

Railway (or other) waybill account No. Wagon (car) No.

Date of receipt of products at the warehouse

Quantity (weight), kg Type of packaging

Numbers of places from which samples were taken (samples or samples)

10 Samples (samples or samples) are selected in accordance with

11 Sampling method (samples or samples), quantity

12 Samples (samples or samples) are selected for storage, sealed and provided with labels (labels)

13 Selected samples (samples or samples) are sent for control or testing in

Surnames and signatures of the commission members:

GOST 24297-2013

Annex B (informative)

Form of act of sampling (sampling or samples)

The act of sampling (sampling or sampling)

This act testifies that samples (samples or samples) were taken for inspection or testing and sealed.

Names and positions of members of the commission

product name

page 1

page 2

page 3

page 4

page 5

page 6

page 7

page 8

page 9

page 10

page 11

page 12

page 13

page 14

page 15

INTERSTATE COUNCIL FOR STANDARDIZATION, METROLOGY AND CERTIFICATION

INTERSTATE COUNCIL FOR STANDARDIZATION, METROLOGY AND CERTIFICATION

INTERSTATE

STANDARD

GOST 24297-2013

2013

Official edition

|

Standartinform |

Foreword

The goals, basic principles and basic procedure for carrying out work on interstate standardization are established by GOST 1.0-2015 “Interstate standardization system. Basic Provisions” and GOST 1.2-2015 “Interstate Standardization System. Interstate standards, rules and recommendations for interstate standardization. The order of development, adoption, updating and cancellation "

About the standard

1 DESIGNED BY OPEN joint stock company"All-Russian Research Institute of Certification" (JSC "VNIIS")

2 INTRODUCED by the Federal Agency for Technical Regulation and Metrology (Rosstan-

3 ADOPTED by the Interstate Council for Standardization, Metrology and Certification (Minutes of June 7, 2013 No. 43)

|

4 By order of the Federal Agency for Technical Regulation and Metrology dated August 26, 2013 No. 544-st, the interstate standard GOST 24297-2013 was put into effect in the Russian Federation for use as a national standard from January 1, 2014.

6 REVISION. September 2016

Information about changes to this standard is published in the annual information index "National Standards", and the text of changes and amendments - in the monthly information index "National Standards". In case of revision (replacement) or cancellation of this standard, a corresponding notice will be published in the monthly information index "National Standards". Relevant information, notification and texts are also posted in the public information system - on the official website of the Federal Agency for Technical Regulation and Metrology on the Internet (www.gost.ru)

©Standartinform, 2016

This standard cannot be fully or partially reproduced, replicated and distributed as an official publication on the territory of the Russian Federation without the permission of the Federal Agency for Technical Regulation and Metrology

Annex B (informative) Compliance label form

Compliance Label

1 Product name_

2 Batch number_

3 Quantity (pieces, kg, m)_

5 Products comply_

Annex D (informative) Form of non-compliance label

Non-compliance label

1 Product name_

2 Batch number_

3 Quantity (pieces, kg, m)_

4 Date of admission to the organization_

5 Number of the act of sampling (sample or sample)_

6 Product does not match_

indicate the document that establishes the requirements

Surname and signature of the person responsible for verification

Annex D (reference)

Products

Receipt Form Safety receipt

Does not comply with the act

name of company

certificate number for custody

Head warehouse

Annex E (informative)

Prohibition form Prohibition

in that it is forbidden to launch products into production_

Name

products

non-compliant

indicate the document that establishes the requirements

The supplier

receipt date

Accompanying documents

Surname and signature of the person responsible for verification

UDC 658.562.014:006.354 OKS 03.120.10 T51 OKSTU0025

Keywords: verification of purchased products; verification methods; list of products subject to verification; organization of verification; verification procedure; registration of verification results

Editor M.I. Maksimova Technical editor V.N. Prusakova Proofreader E.D. Dulneva Computer layout I.A. Naleykina

Signed for publication on September 18, 2016. Format 60x84/a. Ariap headset. Uel. oven l. 1.86. Uch.-ed. l. 1.30. Circulation 38 copies. Zach. 2225.

Published and printed by FSUE STANDARTINFORM, 123995 Moscow, Granatny per., 4. www.gostinfo.ru info@gostinfo.ru

GOST 24297-2013

1 area of use............................................... ....one

3 Terms and definitions .......................................................... ..one

4 Symbols and abbreviations.................................................... one

5 General provisions............................................... .....2

6 Organization of verification of purchased products...............................................3

7 Procedure for verification of purchased products ..............................................4

8 Registration of the results of verification of purchased products .............................. 5

Annex A (informative) Form of the log of verification of purchased products .............................. 6

Annex B (informative) Form of the act of sampling (sampling or sampling) .............................. 7

Appendix B (informative) Compliance label form .............................................. 8

Annex D (informative) Form of non-compliance label .............................................. 9

Annex E (informative) Form of safe receipt .............................. 10

Annex E (informative) Prohibition form ..................................................11

INTERSTATE STANDARD

VERIFICATION OF PURCHASED PRODUCTS Organization and control methods

Verification of purchased products. Organization and methods of control

Introduction date - 2014-01-01

1 area of use

This standard establishes the basic requirements for the organization, procedure for conducting and formalizing the results of verification of purchased products received from the supplier to the consumer.

2 Normative references

4 Symbols and abbreviations

GOST - interstate standard;

ND - normative documentation;

SI - measuring instruments.

Official edition

5 General provisions

5.1 Verification of the purchased products is carried out in order to verify the compliance of the product quality with the established requirements and to prevent the launch of non-conforming products into production or operation.

5.2 Verification of the purchased products is carried out by the personnel responsible for its implementation and having the appropriate authority.

If necessary, specialists from third-party organizations can be involved in product verification on a contractual basis with the definition of the conditions and obligations of the parties for product verification.

Subdivisions and organizations that receive products for inspection or testing must complete them on time and draw up a conclusion on the establishment of the fact of compliance or non-compliance of the quality of the purchased products with the established requirements.

5.3 Verification of purchased products is carried out in accordance with the list of products subject to verification approved by the consumer organization.

5.4 The range of purchased products subject to verification, controlled parameters and properties, type of control and its scope should be determined based on the stability of the quality of suppliers' products, the effectiveness of their quality management systems, and the importance of this parameter.

5.5 Lists of products subject to verification should contain:

Name, brand and type of purchased products;

Designation of ND, the requirements of which the products must comply with;

Controlled properties, parameters and points of their control;

Type of control, methods of control, volume of samples (samples or samples), control standards and decision rules.

NOTE Decision rules are those that allow a solution to be found without any consideration of different options. The peculiarity of decision rules is that the sequence of actions is determined by applying simple procedures on the initial data;

Means of measurement or testing or their technical characteristics;

Instructions on marking (branding) of products based on the results of verification;

Permissible resource consumption during verification.

If necessary, the lists may include requirements or instructions that reflect the features of a particular product.

5.6 Sections of the list of purchased products subject to verification are developed by:

Design services - for products intended for assembly;

Technological services - for raw materials, materials and semi-finished products intended for production, repair, operation and maintenance.

5.7 The lists of products subject to verification are agreed with the person responsible for product verification and metrology (if necessary, with the customer, if this is stipulated in contracts or supply contracts).

5.8 The lists of products subject to verification are approved by an authorized person of the consumer organization.

If necessary, verification of purchased products that are not included in the list can be carried out.

5.9 Verification of purchased products, depending on their volume, can be carried out by complete or selective control or testing. Each of these types of control (tests), depending on the means of obtaining information, its reliability and sufficiency, may include measuring, visual and organoleptic verification methods.

5.9.1 Measurement verification methods should be used in cases where increased reliability of the information received is required and when the means of monitoring and testing products are any measuring instruments and test equipment.

5.9.2 Organoleptic and visual verification methods should be used in cases where the means of control, testing or measurement of products, as a rule, are the sense organs, for example: organoleptic - smell, taste; visual - color, marking, packaging, completeness.

5.9.3 When carrying out complete verification, each item in the purchased lot should be subjected to control or testing in order to identify non-conforming items of product and decide on the suitability of the product for use.

End-to-end verification should be carried out in cases where it is technically possible and economically feasible.

5.9.4 During selective verification of purchased products from a batch of products, samples (samples or samples) are randomly selected, based on the results of control or testing of which a decision is made on the suitability of products for use.

Control or test plans, as well as acceptance rules, must comply with the requirements established in the RD for this type of product, and must be focused on the use of statistical methods.

Rules for selecting product units in the sample - according to GOST 18321.

5.10 When re-submitting a purchased batch of products for verification, it should be indicated that the batch previously recognized as non-conforming is submitted for verification again, so that the person responsible for verification pays special attention to the characteristics due to which it was recognized as non-conforming.

5.11 If necessary, the consumer may conduct additional product checks not provided for in the RD. The scope and methods of verification in this case must be agreed between the supplier and the consumer.

5.12 During verification, if necessary, it is allowed to test components in the conditions and modes provided for by the RD, while the list of products subject to verification should contain appropriate instructions.

5.13 The decision on the need to introduce, tighten, weaken or cancel the verification of purchased products is made by the consumer based on the features, nature and purpose of the product or the results of verification of this or similar products for the past period of time, or the results of using the finished product with the consumer.

6 Organization of verification of purchased products

6.1 The main tasks of the personnel performing product verification are:

Verification of purchased products, as well as execution of documents and records based on the results of verification;

Checking the availability of accompanying documentation for products, certifying its quality and completeness;

Timely issuance of permits for launching products into production based on the results of verification;

Periodic control over compliance by warehouse workers with the rules for storing and issuing products to production;

Informing departments about the quality of purchased products;

Notification of suppliers about the shortcomings and inconsistencies of products identified during verification, in the process of production and operation; calling, if necessary, representatives of suppliers to participate in the acceptance and preparation of acts on non-conformity of products;

Accumulation of statistical data on the level (dynamics) of the quality of products received from suppliers.

6.2 Verification of purchased products should be carried out in a specially designated place equipped with all necessary measuring, control and testing equipment, provided with measurement, control or testing methods for products, as well as the necessary RD for products.

6.3 The conditions under which verification should be performed should be specified.

Such conditions or requirements should include, for example, the requirements for unpacking and preservation of products, the time for the products to enter the operating mode, the elimination of solar radiation, and aggressive environments.

6.4 The sequence of verification should be such that the control or testing of some parameters or properties of the product does not lead to a change in others, as well as hidden defects, if possible, were discovered at the verification stage, and not during production or operation.

6.5 The products are subjected to verification according to the rules and to the extent established in the list or RD for a particular type of product.

6.6 If necessary, verification of products can be carried out in the presence of a representative of the supplier or a third party (if it is stipulated in contracts or supply contracts).

6.7 Products for verification are submitted with accompanying documentation certifying its quality (for example, a certificate, passport, quality certificate, etc.).

6.8 Methods and means of control and testing used in the verification of purchased products should be selected taking into account the requirements for the accuracy of measuring the parameters or properties of products established in the RD for a specific type, as well as in GOST 8.009.

If the measuring instruments and control methods differ from those specified in the RD, then the consumer must agree on the technical characteristics of the measuring instruments used and control methods with the supplier.

If during verification it is found that the measuring equipment does not meet the established requirements, then verification using this equipment should be stopped. Products, during the verification of which these nonconformities were found, should be re-verified using other operable and timely verified means, and based on the results of the re-verification, a decision is made on further actions.

6.9 For verification, the products accepted by the authorized person of the supplier are submitted, together with the accompanying documentation certifying its quality (certificate, passport, quality certificate, etc.), drawn up in the prescribed manner.

7 Procedure for verification of purchased products

7.1 Products received for verification must be stored separately from those previously accepted or recognized as non-conforming based on the results of verification and have an appropriate identification (label, tags, etc.) indicating that the product has not yet been accepted or is under control or testing.

7.2 Verification of purchased products can be carried out at any time from the moment it arrives at the consumer's warehouse and before it is put into production. However, this should take into account the timing of claims, if it is subsequently found that the purchased products do not meet the established requirements.

7.3 When products are submitted for verification without accompanying documentation certifying their quality, in some cases, verification can be carried out for compliance with the current RD for this type of product with the obligatory execution of an act on its actual quality and completeness, indicating the missing documents.

7.4 Before submitting products for verification, if these products are not subjected to verification prior to storage, they must be placed on special sites or in warehouses separately by receipts, batches, brands, names, sizes. When unloading products, the requirements and rules established in the technological maps, methods, diagrams and instructions must be observed.

7.5 Verification of products according to parameters or properties that are not specified in the RD, contracts or supply contracts may be carried out without agreement with the supplier and without the right to make claims on them to the supplier (for example, to develop the production technology of products).

7.6 Unpacking of products, their sorting, delivery to the place of verification, stacking, marking after verification is carried out by the personnel responsible for its storage.

7.7 The personnel responsible for storage must timely submit the purchased products for verification along with the supplier's accompanying documentation certifying its quality and completeness.

7.8 Personnel responsible for product verification should verify:

Completeness and quality of the accompanying documentation certifying the quality of products (certificate, passport, certificate of quality, etc.), with registration in the verification log (Appendix A);

Appearance of products, surface condition, packaging, labeling, presence of mechanical and other damage.

The personnel responsible for verification must also carry out the necessary measurements of the parameters or properties of the product and issue a sampling report (samples or samples) (Appendix B).

7.9 Selection of samples (samples or samples) of products received for verification is carried out by the personnel responsible for its storage, under the control of the personnel responsible for verification, from each incoming batch separately in the volumes specified in the list of products subject to verification, or RD for a specific product type.

7.10 The batch of product from which the samples (samples or samples) are taken and the samples themselves (samples or samples) must be identified.

GOST 24297-2013 8 Registration of results of verification of purchased products

8.1 The personnel responsible for verification, upon receipt of products and applications for verification, must register it in the verification log (see Appendix A) indicating the name, quantity, date of receipt, supplier, etc., followed by the results of the control, tests or measurements of controlled properties or parameters of products, as well as the execution of a sampling report (sample or sample) (see Appendix B).

8.2 If the product conforms to the established requirements, the personnel responsible for verification must decide whether to transfer it to production.

On accepted products, the warehouse staff should issue a conformity label (Appendix B), signed by the personnel responsible for verification, if possible and appropriate.

8.3 Nonconforming product shall be identified with a label of nonconformity (Appendix D) and placed in isolation to prevent inadvertent use or delivery of such product until the supplier decides on further action if the product is not immediately returned to the supplier.

A claim or complaint must be filed for non-conforming products, which are issued to the supplier along with a safe receipt (Appendix D) and an act of sampling (sampling or sampling) (see Appendix B).

8.4 For products found to be nonconforming, the personnel responsible for verification shall issue a prohibition (Annex E) from release into production.

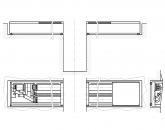

Annex A (informative)

Purchased Products Verification Log Form Purchased Products Verification Log

|

products |

Quality certificate (passport, certificate, etc.) |

packaging |

Place of sampling (sampling or sampling) |

Conclusion about quality, signature of the person responsible for verification |

||||||

GOST 24297-2013

Annex B (informative)

Form of act of sampling (sampling or samples)

The act of sampling (sampling or sampling)

This act testifies that samples were taken (samples or

samples) for inspection or testing and sealed.

1 Names and positions of members of the commission_

2 Product name_

3 Vendor_

4 Railway (or other) waybill_invoice No._

5 Car (car) No. __ g.

6 Date of receipt of products at the warehouse __ y.

7 Quantity (mass), kg_

8 Type of packaging_

9 Numbers of places from which samples were taken (samples or samples)_

10 Samples (samples or samples) are selected in accordance with_

11 Sampling method (samples or samples), number_

12 Samples (samples or samples) are selected for storage, sealed and provided with labels (labels)

13 Selected samples (samples or samples) are sent for control or testing in

Surnames and signatures of members of the commission.

1 area of use

This standard establishes the basic requirements for the organization, procedure for conducting and formalizing the results of verification of purchased products received from the supplier to the consumer.

5.10 When re-submitting a purchased batch of products for verification, it should be indicated that the batch previously recognized as non-conforming is submitted for verification again, so that the person responsible for verification pays special attention to the characteristics due to which it was recognized as non-conforming.

5.11 If necessary, the consumer may conduct additional product checks not provided for in the RD. The scope and methods of verification in this case must be agreed between the supplier and the consumer.

5.12 During verification, if necessary, it is allowed to test components in the conditions and modes provided for by the RD, while the list of products subject to verification should contain appropriate instructions.

5.13 The decision on the need to introduce, tighten, weaken or cancel the verification of purchased products is made by the consumer based on the features, nature and purpose of the product or the results of verification of this or similar products for the past period of time, or the results of using the finished product with the consumer.

6 Organization of verification of purchased products

6.2 Verification of purchased products should be carried out in a specially designated place equipped with all necessary measuring, control and testing equipment, provided with measurement, control or testing methods for products, as well as the necessary RD for products.

6.3 The conditions under which verification should be performed should be specified.

Such conditions or requirements should include, for example, the requirements for unpacking and preservation of products, the time for the products to enter the operating mode, the elimination of solar radiation, and aggressive environments.

6.4 The sequence of verification should be such that the control or testing of some parameters or properties of the product does not lead to a change in others, as well as hidden defects, if possible, were discovered at the verification stage, and not during production or operation.

6.5 The products are subjected to verification according to the rules and to the extent established in the list or RD for a particular type of product.

6.6 If necessary, verification of products can be carried out in the presence of a representative of the supplier or a third party (if it is stipulated in contracts or supply contracts).

6.7 Products for verification are submitted with accompanying documentation certifying its quality (for example, a certificate, passport, quality certificate, etc.).

6.8 Methods and means of control and testing used in the verification of purchased products should be selected taking into account the requirements for the accuracy of measuring the parameters or properties of products established in the RD for a specific type, as well as in GOST 8.009.

If the measuring instruments and control methods differ from those specified in the RD, then the consumer must agree on the technical characteristics of the measuring instruments used and control methods with the supplier.

If during verification it is found that the measuring equipment does not meet the established requirements, then verification using this equipment should be stopped. Products, during the verification of which these nonconformities were found, should be re-verified using other operable and timely verified means, and based on the results of the re-verification, a decision is made on further actions.

6.9 For verification, the products accepted by the authorized person of the supplier are submitted, together with the accompanying documentation certifying its quality (certificate, passport, quality certificate, etc.), drawn up in the prescribed manner.

7 Procedure for verification of purchased products

7.1 Products received for verification must be stored separately from those previously accepted or recognized as non-conforming based on the results of verification and have an appropriate identification (label, tag, etc.) indicating that the product has not yet been accepted or is under control or testing.

7.2 Verification of purchased products can be carried out at any time from the moment it arrives at the consumer's warehouse and before it is put into production. However, this should take into account the timing of claims, if it is subsequently found that the purchased products do not meet the established requirements.

7.3 When products are submitted for verification without accompanying documentation certifying their quality, in some cases, verification can be carried out for compliance with the current RD for this type of product with the obligatory execution of an act on its actual quality and completeness, indicating the missing documents.

7.4 Before submitting products for verification, if these products are not subjected to verification prior to storage, they must be placed on special sites or in warehouses separately by receipts, batches, brands, names, sizes. When unloading products, the requirements and rules established in the technological maps, methods, diagrams and instructions must be observed.

7.5 Verification of products according to parameters or properties that are not specified in the RD, contracts or supply contracts may be carried out without agreement with the supplier and without the right to make claims on them to the supplier (for example, to develop the production technology of products).

7.6 Unpacking of products, their sorting, delivery to the place of verification, stacking, marking after verification is carried out by the personnel responsible for its storage.

7.7 The personnel responsible for storage must timely submit the purchased products for verification along with the supplier's accompanying documentation certifying its quality and completeness.

7.8 Personnel responsible for product verification should verify:

Completeness and quality of the accompanying documentation certifying the quality of products (certificate, passport, certificate of quality, etc.), with registration in the verification log (Appendix A);

Appearance of products, surface condition, packaging, labeling, presence of mechanical and other damage.

The personnel responsible for verification must also carry out the necessary measurements of the parameters or properties of the product and issue a sampling report (samples or samples) (Appendix B).

7.9 Selection of samples (samples or samples) of products received for verification is carried out by the personnel responsible for its storage, under the control of the personnel responsible for verification, from each incoming batch separately in the volumes specified in the list of products subject to verification, or RD for a specific product type.

7.10 The batch of product from which the samples (samples or samples) are taken and the samples themselves (samples or samples) must be identified.

8 Registration of results of verification of purchased products

8.1 The personnel responsible for verification, upon receipt of products and applications for verification, must register it in the verification log (see Appendix A) indicating the name, quantity, date of receipt, supplier, etc., followed by the results of the control, tests or measurements of controlled properties or parameters of products, as well as the execution of a sampling report (sample or sample) (see Appendix B).

8.2 If the product conforms to the established requirements, the personnel responsible for verification must decide whether to transfer it to production.

If you are a user of the online version of the GARANT system, you can open this document right now or request hotline in system.

Popular

- Program for changing the angle of attack and pitch

- Actual output speed Calculation of closed gear train

- What is the procedure for the use of official transport by an employee

- aircraft fuel system

- Agreement for the evacuation of a vehicle Standard agreement for the evacuation of a vehicle

- Bulldozer performance and how to improve it Basic information about bulldozers

- Toyota Production System (TPS) and Lean Manufacturing

- Examination tickets by profession line pipe fitter

- What to do if you don't feel like doing anything

- Globus - shops for the whole family