Equipment for the production of pvc gloves. Production of cotton gloves

To develop a business for the production of gloves, a minimum technical equipment is sufficient. It is worth preparing the premises, purchasing raw materials and equipment, attracting working personnel, and training them, if necessary, in the production craft. Special attention should be paid to the purchase of machine tools in order to open your own business, quickly establish production and supply products to the stream.

Main types of equipment

Today, Russian manufacturers offer equipment and auxiliary tools for the production of gloves in a wide range and at attractive prices. But before buying machines, it is important to pay attention to such parameters as:

- operating conditions;

- specifications;

- manufacturer rating;

- price.

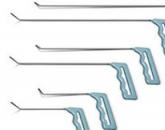

To establish the production of gloves, you will definitely have to purchase the following main types of technological equipment:

- knitting machine;

- overlock;

- machine for applying a layer of PVC on the inside of gloves;

- packing machine;

- storage basket for dumping semi-finished products.

knitting machine

Knitting machine as the most important in the production of work gloves. Models are different in classes: 5,7,8, 10, 13, 15, depending on the number of loops in an inch. The higher the class, the thinner the knitting for the production of cotton gloves. For the production of blanks, the machines are equipped with reels. The models are fully automated and operate on approximately the same principle. The main task is to set the required number of rows and loops, then display the indicators on a digital monitor.

Purpose of overlock

Overlock as a machine for the production of the final stage in the manufacture of work gloves. The glove overlock is equipped with a cuff overcasting function, i.e. it helps to improve the properties of protective products for gloves.

Glue spreader

Machine for applying a layer of PVC on the inside of gloves. Thanks to this unit, it is possible to apply screen printing using a standard matrix.

After applying the PVC layer, the gloves must be dried in a drying chamber. The machines are fully automated. Polyvinyl chloride is supplied from containers, and the composition is applied in a thin layer. Thanks to the device drawing any drawing and a logo is possible. For the accuracy of the sketch, the built-in sensor and the matrices supplied with the device for drawing a picture are responsible. Productivity can reach up to 1300 pairs per hour.

Packing machine

Packaging machine for packing gloves with a capacity of up to 200 pairs per hour. But already in boxes, bags or bags, products are packed manually. When purchasing a packing machine of the GD-T brand, it is possible to apply bank gum.

Matrices and sensors are included with the machines, which are responsible for the accuracy of drawing a pattern with location in certain places.

Chinese manufacturers offer equipment with the ability to apply a PVC layer of different thickness and pattern on gloves from the palm side. As a rule, screen printing is applied with a standard matrix, then the products are sent to the drying chamber.

Popular models, rating

Russian manufacturers of equipment for the production of cotton gloves are considered the best, but there are models from Europe and China on the market.

AURORA

AURORA specializes in the production of knitting machines models - 10C-12-1, 7C-12-1, 15C-12-1 with a capacity of up to 15 pairs per hour. They are fully automated, equipped with a computer and a speed controller with the possibility of working with different raw materials. The cost is low - 190-365 thousand rubles. R.

JOMDA

JOMDA classes - 7, 10, 13 with a capacity of up to 163 pairs per hour. Models are equipped with a computer with the possibility of using different yarns.

SALUT-02 is an energy-intensive overlock machine with a capacity of 1500 pairs per day with a cuff processing function to increase the value of products on the market. Price 40–45 thousand rubles.

PPM-1-M2

PPM-1-M2 as an inexpensive model with a raw material consumption of up to 9 g per 1 pair for applying PVC, thereby giving the gloves greater strength and durability. Cost - 180-200 thousand rubles.

GD-DA

GD-DA knitting glove device with knitting classes 10, 13, 150G and capacity up to 330 pairs per day. Power - 250 kW, weight - 250 kg, dimensions - 1250x650x1750 mm.

BX203

BX203 is a knitting machine with knitting classes 7.10G, capacity 360 pairs per day, power 250 kW and production of glove sizes S, M, L, 2L.

Overlocker from Russian manufacturers with a rotation speed of the working shaft - up to 4000 stitches per minute, weight - 45 kg, engine power - 0.2 kW, productivity - up to 1500 pairs in 8 hours.

PPM-1-M2

PPM-1-M2 - unit for applying spot PVC coating with a capacity of up to 250 pairs per hour, plastisol consumption - up to 9 g per 1 pair, weight - up to 160 kg. The average cost is 80 pairs per day.

GPM-09

GPM-09 is an easy-to-maintain and energy-intensive packaging machine, thanks to which the gloves acquire a marketable appearance and retain their shape. The production process is fully automated. The package contains 12 pairs of gloves. Productivity - 3000 pairs in 78 working days. The cost is 5000 rubles.

MG-C-7/10G

Glove machine from Korean manufacturers. All production cycles are included in the work. The unit has convenient navigation for the tasks of the desired knitting mode, automatic processing of edge loops and trimming material at your fingertips. Productivity - up to 360 pairs per hour. The cost is 200,000 rubles.

JACK BX203-10G

This is an inexpensive analogue from Chinese manufacturers. Fully automated, works on the principle of solid knitting with the ability to use any yarn for knitting (mittens, mittens, gloves). The unit is equipped with a high level of self-control, a smooth transition to manufactured products and a built-in device for the deposition of used parts. Price 200–210 thousand rubles

Product selection

It is from the purchase of the right high-tech equipment that the business and the quality of products in the future will depend. When choosing machines, pay attention to:

- quality, since cheap analogues will lead to poor quality, frequent breakdowns and slowdown in the production process;

- availability of certificates to avoid buying fakes;

- equipment power and customer reviews can be read on the Internet;

- technical equipment, because when producing gloves, it is necessary to take into account the technology for the production of gloves.

Many modern models are multifunctional, equipped with an electronic control unit for quickly setting up production and producing quality products. Given the rating of manufacturers, it is better to buy from reputable companies offering warranty and post-warranty service.

It is possible to purchase additional machines to give gloves more advantages:

- strength;

- environmental friendliness;

- air passage;

- low cost.

With a limited budget, you can start by purchasing Chinese equipment with pretty good performance, automatic computerized control.

According to experts, for a thorough opening of a business for the production of work gloves, it is enough to purchase 5 machines. But many other factors will affect the profitability of production:

- performance;

- power;

- degree of speed.

If desired, today it is possible to lease equipment, but it will be more expensive than buying used equipment. But you can expect to receive high-quality equipment.

Cost of equipment

Newcomers to the business in business are advised to purchase used glove making equipment first, as PVC knitting machines are expensive. In order to save money, you can purchase equipment for only 65–70 thousand rubles. The cost for fully computerized machines is 250–300 thousand rubles.

Computer-controlled machines cost from 300,000 rubles. When choosing, it is important to take into account the technical and operational characteristics of the units, since large losses can be incurred in the event of equipment malfunctions and breakdowns.

Approximate prices:

- knitting machine with a capacity of 16 pairs per hour - 250–270 thousand rubles;

- overlock glove with a capacity of 190 kg per hour - 110-11 thousand rubles;

- knitting machine with an electronic control unit - up to 400,000 rubles;

- device for applying PVC with a capacity of 800 kg / hour on average - 930,000 rubles;

- packaging machine with a capacity of 430 kg / hour - 45,000 rubles.

The cost is directly affected by productivity, the country of manufacture. In terms of price and quality, units from Japanese manufacturers are leading today. Price - 200,000 rubles.

The advantages remain with computerized units with a high level of self-control and a smooth transition to the production of other products. The cost of such units is over 200 thousand rubles. Although needle breakage or thread breakage may occur.

If the budget is too limited, you can buy Chinese counterparts with good performance, automatic tuning and combined control. Prices for used equipment are much lower.

Features of production equipment

Any technique in the production of gloves requires regular maintenance, maintaining high quality and competitiveness of products. It is important to carry out the modernization of existing equipment in a timely manner in order to regulate your business and, as a result, get a good profit.

Payback up to 1.5 years with the purchase of complete equipment - up to 300,000 rubles. The sale of cotton gloves is a fairly stable and stable business. But when opening your own workshop, it is important to competently approach the preparation of a business plan, study the demand of the population and offers, calculate preliminary costs and draw up a detailed scheme.

Given the small financial injections, and high profitability, own production of gloves is a tempting idea, against the backdrop of a crisis that does not cease to torment the population of Russia. Demand for them never falls, and given the constant injection of the state into the construction industry, it will only grow.

Due to the nature of the professions where they are used, these gloves are simply irreplaceable. In addition, the use of protective equipment is prescribed by Russian law, in the safety rules.

To establish a business in this area, you will need a minimum of technical equipment.

- Room for work.

- Equipment.

- Working staff.

To understand how the production process takes place, you need to delve a little into the technical equipment of the workshop.

The knitting process is carried out on one machine. Average output is approximately 360 pairs per shift. Parameters can be adjusted manually or set by a specialized program, in more expensive models.

For better profitability and production speed, it is recommended to purchase models with a large number of needles (at least 15). This affects the density of knitting, and, accordingly, the quality of the gloves as a whole. To increase the demand for the product, overlock equipment can be used, which allows finishing the edges to prevent the dissolution of the thread.

Types of machines for the manufacture of gloves

In the production of gloves, the main emphasis is on a good machine. The bar of leadership in this area is held by the Japanese manufacturers of Shima Seiki devices. Korean knitting machines breathe in their backs, and Chinese models should not be discounted. They do their job well, and the inexpensive cost will allow you to start a business on a small budget.

According to the principle of operation, knitting machines are of two types:

- Automatic. Here the program works in automatic mode, and the necessary knitting parameters, such as the number of rows or lines, are set on a special display.

- Manual. Here, the required set of loops is determined and set by a special plastic chain, by changing the number of links in it.

From additional equipment you will need the following:

- Overlock.

- Apparatus for applying protective layers.

- Packing line.

Manufacturers and cost of knitting machines

The cost of the machine depends on its performance and country of origin. As mentioned, the leadership bar is held by Japanese devices. But models of knitting machines from the Land of the Rising Sun are expensive, and not every novice businessman can purchase them. You can start with simpler machines.

Korean Computerized Glove Machines (MG-C-7/10G - Grades 7 and 10)

All production cycles are included in the work, due to which the need to purchase an overlock is excluded. Convenient navigation with a keypad allows you to quickly set the required knitting mode, and quickly change product sizes.

Automatic edging and fingertip trimming minimizes the presence of personnel. Full control is exercised by one person. Automatic lubrication system and breakage shutdown reduces the possibility of misuse of the thread to zero.

Performance.

- Grade 7 gloves - 360 pairs.

- Grade 10 gloves - 250 pairs.

The cost is from 96 thousand rubles to 200,000.

Chinese Knitting Machine Model - JACK BX203-10G

An automatic machine that works on the principle of one-piece knitting. Complete computerized control, perfect technology and two-block device, makes the knitting process of high quality.

It can work with any thread, knits both ordinary gloves and mittens, mittens, fingerless models.

Advantages of the device

- Computerized control.

- High level of self-control.

- Smooth transition to the release of other products.

- Built-in automatic device for the deposition of the spent part.

- Automatic stop when the thread breaks or the needle breaks.

- Served by one person.

Cost - 210.560 rubles.

Where to begin

The question of choosing a model depends on financial capabilities. If you have sufficient initial capital, then you can purchase an expensive model, Korean or Japanese manufacturers. The quality of these machines is time-tested, and you can quickly recoup their cost.

If the budget is very limited, then Chinese models also show themselves well. They have good performance, automatic adjustment and fully computerized control. It is possible to start a business for the production of gloves on such machines with minimal financial investment.

Definitely not worth buying a used model. No one will tell you how many cycles they have worked, and in fact this is a pig in a poke. Deciding to save on an inexpensive machine, you can then thoroughly invest in its repair.

Requirements for yarn and the number of personnel for production

For knitting gloves on automated machines, the following types of thread are used:

- 100% cotton or similar with synthetic added for durability.

- 100% wool with a little bit of synthetic.

- Artificial PVC thread.

To obtain a high density of the material, special parameters are set on the machine during manufacture. The palmar part can be coated with a rubber coating, solid or stencilled, in the form of small droplets.

Depending on the type of equipment used, the entire process requires a minimum number of operators. This is 2-3 people per line, depending on the volume of productivity.

Installation and adjustment of machines for the production of gloves

Having simple technical equipment, machines for glove production can be installed independently.

What is needed for this?

- Flat concreted area.

- Electricity supply.

- Grounding.

During installation, horizontal stability is adjusted by articulated legs, twisting in turn. Electricity must be carried out along the wall, and in front of the machine, make a hotel switch for emergency shutdown.

Setting up automatic devices is not required. All operating modes are set on the display. On machines with manual control, the number of threads for knitting is adjusted. To do this, the kit comes with specialized equipment.

Profitability of glove production

The amount of revenue and full payback depends on many factors. First of all, it is the cost of the equipment itself. You can purchase an inexpensive model, but accordingly it will have less performance, and the minimum speed.

The amount of revenue and full payback depends on many factors. First of all, it is the cost of the equipment itself. You can purchase an inexpensive model, but accordingly it will have less performance, and the minimum speed.

Expensive machines are able to work in an accelerated mode, but the payback, in fact, will be the same, in time. Taking into account the acquisition, the newest machine, Korean production, with overlock and automatic adjustment, the productivity of which averages 360 pairs per shift, the figures are as follows.

- Full cost including rent, technical equipment, purchase of raw materials, wages for a month, registration of an enterprise - this is about 300 thousand rubles.

- The minimum cost of one pair on the market- 12-15 rubles. Taking into account production costs: light, rent and raw materials, the final price will be about 6-8 rubles.

- Thus, the net profit from one machine per month is about 52 thousand.

Accordingly, if you invest more thoroughly and purchase five machines, you get about 3,000 thousand rubles a month. Thus, everything will pay off in 6-8 months.

But costs can be significantly reduced if you have your own free space, for example, a large garage. This is very convenient, to start work, you only need to level the site by concrete it.

Realization of gloves

It is better to think about the sales market before starting work. A single point of sale, production does not pay off for a long time. It would be nice to agree in advance with factory enterprises, workshops, construction companies on the supply of gloves. Having solved this issue, you can safely begin to implement an action plan for the promotion of production.

What we have - results

There is no tension in the market of equipment for knitting gloves. And yes, there is a lot of competition. Therefore, it is worth addressing this issue without breaking off into a long box. Entrepreneurial people are enough, and everyone is trying to make money by considering such a business plan.

The idea of making cotton gloves is not unique. But this business will always be profitable, since such gloves have a very wide application. The profitability of the business is 20-30%. The payback period is about two years. And investments go for the most part only for the purchase of an automated production line and raw materials.

It is best to organize a business as an individual entrepreneur on a simplified taxation system. But if you plan to sell products through wholesalers, to enterprises, especially large ones, you will have to work with VAT. In this case, a general taxation system will be required.

Production room

There are no special requirements for the premises for the production of cotton gloves. It must be at least 80 sq. m., be heated and have wiring with an industrial mains voltage of 380 watts. As a rule, up to 15 machines are installed on such an area.

The price for renting a room varies depending on the location. Significant savings on rent can be achieved by locating production facilities outside the city limits. But then the cost of logistics increases. An average of 20-30 thousand rubles should be allocated for rent.

Glove manufacturing technology

The production of cotton gloves takes place according to a certain technology in several stages:

- knitting blanks;

- overcasting the edges of workpieces;

- application of a dot coating of polyvinyl chloride on the palmar part;

- product packaging.

Glove Manufacturing Equipment

The business will require the purchase of special equipment not only for production, but also for packaging. These are all separate machines. In addition, the business plan must include the procurement of raw materials. All this can be chosen on the market according to your budget and scope of the enterprise.

For the manufacture of cotton products you will need:

- raw materials (for two months) - 37.5 thousand rubles;

- automated knitting machines - 115 thousand rubles;

- overlock - 33 thousand rubles;

- machine for applying PVC coating - 230 thousand rubles;

- packaging machine - 19 thousand rubles.

As for the consumables, for the manufacture you will need the following raw materials:

- cotton yarn, wool, mixed - 0.15 rubles / g .;

- latex gum - 0.39 rubles / g .;

- plastisol - 0.06 rubles / g .;

- thread for overcasting - 0.33 rubles / g .;

- latex thread - 0.40 rubles / g.

Please note that cotton blended yarn is in greatest demand in production. Rayon, wool, acrylic and other additives are usually added to cotton, depending on the type of gloves being produced. Always look who is the producer of cotton. The better the climatic conditions for the cultivation of cotton in the producing country, the better the yarn is offered. Let's say, choosing between India and China, it is better to give preference to India. Be that as it may, you should always ask the supplier for a quality certificate. The cost of the wholesale purchase of mixed yarn is about 90 rubles / kg.

Sales routes for finished products

Traditionally, the marketing plan should include the following areas:

- construction sites;

- workshops;

- housing sector;

- private farms;

- other.

Also, the business plan should include the possibility of retail sales. In almost every home, sometimes there is a need for such gloves. Accordingly, it is worth considering how to produce products for various requirements. For example, gloves can be produced in various weights, sizes, uncoated or coated. In accordance with the range, the price of finished products may vary.

You can conclude contracts for the purchase of goods with:

- retailers;

- wholesalers large and small;

- enterprises;

- Housing and communal services, city organizations, communal services.

Staff

The business has its advantages - the machines are fully automated, so there is no need for highly qualified personnel. The seamstress's work plan includes only the timely replacement of yarn and the collection of finished products. 4 people are enough to service 15 machines.

The plan for the formation of service personnel should include:

- seamstress on knitting machines;

- seamstress for overlock;

- PVC machine operator;

- packer.

In addition to them, the business plan must provide for the work of a driver, one or more sales managers, and an accountant. Workers are usually paid piece-rate bonuses. In total, 150 thousand rubles must be left for wages. per month.

Investments and their return

If we summarize the costs of raw materials, equipment, rent and wages, investments will amount to at least 2.2 million rubles. The cost of one pair of gloves with a density of 42 g, including the cost of raw materials and electricity, is about 6 rubles. With wholesale sales, the price will rise to 11-14, and at retail - up to 16-18. For a month, you can receive about 370 thousand rubles, and taking into account all the deductions, the profit will be 84 thousand rubles. In total, the business will pay off in a little more than two years.

The most profitable, but at the same time more costly type of business, is the business of producing something. In this article, we will be looking at the Polyvinyl Chloride (PVC) Coated Cotton Gloves business.

Technological process of production

The production of cotton gloves is not particularly difficult, but, nevertheless, it has a number of features and nuances that you should know. The technology itself consists of the following steps:

- tying the workpiece;

- processing the edge of the cuff of the workpiece;

- PVC coating;

- finished product packaging.

Equipment and machines for production

The simplest set of equipment that is needed for the production of PVC coated gloves consists of:

- machine for knitting workpieces;

- overlock for cuff processing;

- PVC coating machine;

- packaging machine.

Equipment can be purchased new directly from the manufacturers of this equipment, but if the budget is very limited, then you can buy used machines. Used equipment will cost much less than new and it may make sense to buy it, but more expensive brands.

A new device for knitting future gloves (glove knitting machine) costs from 75 to 100 thousand rubles (in the middle price segment). As you can see, the price of the machine for the production of gloves is quite acceptable. Overlock, for processing the cuff of the workpiece, with a capacity that is capable of producing up to 200 pairs of gloves per hour, costs about 35 thousand rubles. The most expensive in terms of cost will be a machine for applying PVC coating. The cost of such a unit is at least 250 thousand rubles. The packaging unit costs about 20 thousand rubles.

Production business plan

To understand how much money you need to start a business that will be associated with the production of PVC coated gloves, you need to draw up a detailed business plan, taking into account all upcoming costs. To do this, we will calculate a business plan.

First, let's look at current expenses. The following items of expenditure should be noted here:

- staff salary from 40 thousand rubles per month;

- rent of premises for production from 30 thousand rubles per month;

- utility costs from 20 thousand rubles per month;

- raw materials for the production of 30 thousand pairs per month from 70 thousand rubles per month.

Total expenses per month will be at least 160 thousand rubles.

To start production, it is necessary to purchase equipment. Consider the cost of acquiring new equipment. In the previous chapter, the necessary equipment for the production line was described, the price of the machine for knitting cotton gloves. The cost of the production line will be at least 380 thousand rubles.

Thus, to ensure the smooth operation of your enterprise for six months, you need at least 1,430 thousand rubles. At the same time, you should provide for more funds for paying taxes, in the amount corresponding to your taxation system. And some money for unexpected expenses.

Considering monthly expenses and production capacity, it is not difficult to calculate that the cost of one pair of gloves will be 5 rubles 33 kopecks. Wholesale gloves are bought at a price of 11 rubles. The cost of retail sales is from 16 rubles for one pair of gloves. When selling gloves in bulk, you will receive at least 5 rubles 67 kopecks per pair. Thus, the profit per month will be 170 thousand rubles.

Read also: sawdust production

The time for which the equipment for the production of cotton gloves with PVC will pay off will be at least 12 months, taking into account all current and capital expenses, taxes and unforeseen expenses. Thus, the enterprise can be considered as a very interesting form of business with a quick payback.

Documents for starting a business

In order not to have a lot of problems with the law, it is best to start registering a business even before it starts working. That is, it is better to buy a machine for making gloves at the same time as paperwork. To formalize the form of ownership of such a small enterprise, you need to choose between registering yourself as an individual entrepreneur (IP) or making a limited liability company (LLC). At the same time, it should be taken into account that if you plan to cooperate with enterprises, then you will need a tax regime that will allow you to work with VAT. If you plan to sell your products to wholesalers, and not to enterprises, then you can choose a simplified taxation system (STS), which provides for two options for calculating tax - 6% of total revenue or 15% of profit.

When choosing between an individual entrepreneur and an LLC, it should be taken into account that the entrepreneur, in case of any violations, is liable with all his property, and the LLC - only in the amount of the authorized capital. But the penalties for sole proprietorships are much lower than for LLCs. It's up to you to decide.

Room selection

When looking for premises for opening a production workshop, pay attention to premises with an area of 50 square meters located in the industrial zone of the city or at a small distance from the city. This location of the workshop will allow you to significantly save on the cost of rent and will help to avoid problems with disgruntled neighbors who can be disturbed by noise and bad smell.

Since there will be more than one machine for the production of gloves, the area of \u200b\u200bthe room must be appropriate. The area will depend on the amount of equipment to be installed.

When examining the premises, you should pay attention to the presence of voltage in the network of 380 volts, the presence of water and sewerage. Also, the room must comply with sanitary and fire safety standards.

Do not forget that the room must be heated. Otherwise, taking into account the weather conditions in most of our country, your workshop will not be able to work in the winter, and this is no less than 4-5 months a year.

Sales market analysis

PVC coated gloves are a fairly popular product. They are required not only in production and construction, but also in everyday life. Therefore, the demand for such products is quite high.

The cost of gloves for bulk purchases is from 11 to 13 rubles. In a retail network, they can be sold at a price of 16 to 20 rubles for a pair of gloves. You can set up sales of products through:

- building stores;

- stores selling garden tools;

- wholesale firms that supply consumables to enterprises.

Popular

- Profitable business: how to open a marriage agency

- Paving slab production business plan from a to z How to open a paving slab manufacturing business

- Franchise cost and cost of ownership

- How to open a recruitment agency

- Typical mistakes when renting premises for a store

- How to get a license to trade in flowers

- Classification of business centers and shopping centers

- Potato growing business: sales features and profit

- New projects in Russia to be led by Dmitry Sokov New projects in Russia will make EuroChem a world leader

- Where Nordman tires are made