Car dent removal business. Removing dents without painting as a business at a car service Removing dents on a car as a business

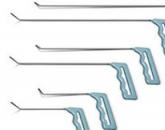

The main idea of the business is to remove dents without having to paint the car. This became possible with the advent of special devices - the DOL tool in the form of several variations of hooks.

Paintless dent removal technology was pioneered by the German company Karosseriebau Nuessle in 1972. As it turned out, you can eliminate almost any dent on the body if you use a special set of tools. However, only 20 years later the Nussle Spezialwerkzeuge brand appeared on the market. The company is actively engaged in the sale of not only equipment for car straightening, but also training courses that teach this technology.

Our business valuation:

Starting investment - 300,000 rubles.

Market saturation is average.

The complexity of starting a business is 3/10.

business concept

The do-it-yourself dent removal business is based on the idea of car body repair. The work is done with special hooks of several types. The master exerts the required pressure at certain points with these devices and returns the metal to its original shape. On the outside, adhesive equipment is used to straighten dents. At the same time, it is not special tools that are the main factor in the success of a business in this area, but the professionalism of the master doing the work. He must have the skills to work with metal, understand the difference in its thickness, be able to choose a tool for various situations.

Advantages of the idea

Using equipment to remove dents on cars without painting is very beneficial, since the paint surface of the body remains intact. Eliminating the need for painting significantly reduces repair costs by up to 50% when compared to the cost of repairing dents with traditional methods.

The advantages of using the technology include the following:

- Repair speed. Elimination of complex body defects takes several hours, minor dents are straightened within an hour. Traditional car straightening works take at least two days, even if the damage is light.

- The car after repair is immediately ready for full operation.

- The quality of the repair work. After the elimination of defects, the coating remains unchanged, and, therefore, the car will not go into the category of “painted” and its value will not decrease.

- The price of removing dents is several times cheaper than the standard straightening of a car with subsequent painting.

True, it is worth noting that only certain dents can be straightened using this technology. If the car is too damaged and the defect turned out to be “pointed”, then such repairs will not be effective.

Necessary equipment

The starter kit for removing small dents without painting includes special hooks of different sizes (about 13 pieces). In addition, you will need an adhesive system, a mini-lamp and additional accessories such as caps, a mini-lifter, glue remover, expander pad, mounting spatula, and more. In general, in order to buy tools for removing dents without painting, you will need about 100 thousand rubles. Professional equipment of the German brand Nussle Spezialwerkzeuge will cost more, since the price of hooks from this company is from 2 to 9 thousand rubles.

The starter kit for removing small dents without painting includes special hooks of different sizes (about 13 pieces). In addition, you will need an adhesive system, a mini-lamp and additional accessories such as caps, a mini-lifter, glue remover, expander pad, mounting spatula, and more. In general, in order to buy tools for removing dents without painting, you will need about 100 thousand rubles. Professional equipment of the German brand Nussle Spezialwerkzeuge will cost more, since the price of hooks from this company is from 2 to 9 thousand rubles.

But PDR repair specialists do not advise starting a business with large expenses, but recommend purchasing the usual common kit - a set of hooks, a reverse hammer, glued equipment and so on.

Technology Description

PDR technology is a special device for removing dents on the body. Its use eliminates the need for painting after straightening the defect. It is possible to eliminate dents of various depths and complexity on any part of the car. Due to the use of internal vacuum suction cups and special microlifts, even the deepest lesions are pulled out without much effort.

In general, repair work does not require the preliminary dismantling of parts. But sometimes it is necessary to disassemble parts of the car in order to gain access to the damaged area. The body is repaired with standard tools, but the main device for straightening defects are hooks and levers equipped with various tips and comfortable handles. It is extremely important to choose the right tool for the job, as the speed and quality of the repair depends on it. In almost all cases, the deformation is eliminated from the inside of the body.

For constant monitoring of the alignment process, special mini-lamps are used. An experienced craftsman gradually straightens the dent by alternately pressing and lifting certain sections of the body. It is simply impossible to perform this procedure without having the necessary knowledge and experience. Competent actions ensure the elimination of small defects in a couple of seconds. Priority tasks for obtaining a positive result are the correct selection of a tool and a scheme of actions.

Masters and training

To obtain the skills you need in repair, there are specialized centers where you can be trained to remove dents without painting. The course will cost about 20-70 thousand rubles. Such a run is explained by the difference in the duration of training. Some centers teach for just a couple of days, while others for up to several weeks. In addition, private specialists are engaged in teaching the technology of straightening a car without painting. Basically, these are masters working in this direction.

To obtain the skills you need in repair, there are specialized centers where you can be trained to remove dents without painting. The course will cost about 20-70 thousand rubles. Such a run is explained by the difference in the duration of training. Some centers teach for just a couple of days, while others for up to several weeks. In addition, private specialists are engaged in teaching the technology of straightening a car without painting. Basically, these are masters working in this direction.

The process of learning how to remove a dent on a car without painting takes place in an intensive mode and often with practical skills in eliminating defects. The main emphasis is on acquiring the ability to see the dent with the help of lamps and control the location of the tools. That is, the setting of the hand of the future master is performed.

room

You can use the dent remover at home using your own garage. If you don't have your own garage space, you can rent it. At the same time, it is important to take into account that it may be necessary to repair not only small cars, but large jeeps. So, it is better to foresee this fact in advance and choose a garage with an area of at least 30m2 with good lighting and heating.

Registration

To legally conduct business, you need to register an individual entrepreneur with the local tax service. Setting up a business will not take much time, the whole process will take about 7 days and will cost about one thousand rubles.

Costs and profits

In general, the opening of a workshop will require capital in the amount of 100-150 thousand rubles, based on the fact that the entrepreneur has his own premises at his disposal. If the garage needs to be rented or refurbished, then start-up costs increase.

If we talk about possible profits, then the cost of removing a dent on the hood largely depends on the complexity of the work, as well as on the size of the defect. The price range ranges from 1.5-5 thousand rubles. One master can handle the repair of 5-6 cars in an eight-hour shift. If we take the price of 2 thousand rubles for calculation, then the daily income will be 10-12 thousand rubles. In a month it will be from 300 thousand and above.

It is worth noting that almost all profits will be net if you work independently in your own premises. Renting a garage will cost about 15 thousand rubles, taxes 6% of total income. Or about 18 thousand rubles, if you work under a simplified taxation scheme.

Advertising

To promote your business and attract the attention of potential customers, you can use such an option as distributing business cards, advertising brochures and other things. You can also conclude an agreement with an auto parts store on mutually beneficial cooperation. They will advertise the services of the workshop, and the craftsmen will recommend them to their clients.

Cons business ideas

The most important disadvantage of business is dependence on employees. Of course, you can work independently, but this option is not always possible. At the same time, it is highly likely that a hired and trained employee will open his own business as soon as he acquires the necessary skills and a client base. Experienced auto repair specialists recommend concluding an agreement with employees, according to which they will have to work for a certain period of time for training or reimburse expenses.

PDR business preferences

We often talk about the PDR tool, its history, application features and paintless dent removal competitions. However, today, together with Sergey Chubukin, director of Av-Masters, the manufacturer of Av-Tool, we decided to delve into the issues of building such a business. We publish a recording of our conversation.

Sergey, I propose to start our conversation with a discussion of the key and standard question in these times: what is the current situation in the industry of paintless dent removal?

- If we talk about PDR as a service and repair, then in general the market behaves predictably, and the situation is stable. Many representatives of the classical school of body repair argue that due to a significant rise in the cost of consumables, the price of their work has increased, and, accordingly, car owners are looking for cheaper alternatives. However, we did not see a surge of interest.

The fact is that those customers who receive minor damage today prefer not to repair them at all. They save on aesthetics.

Here is a banal example. Cars with hail damage often come to us. Usually 10-20 dents are localized on the hood, roof, fenders and trunk. PDR-repair relieves the owner of the car from such a headache as repainting almost the entire body. Not only enormous funds are saved, but also the client's time, as well as nerves when reselling the car. After all, no one in the secondary housing needs a car with putty on the roof. Having learned the cost of repair, it usually varies within 10-20 thousand for the above-mentioned volume of dents, the client prefers to postpone the repair altogether.

And some even ask questions about pricing and demand discounts. They see a craftsman in clean jeans and a trendy T-shirt, and a set of shiny tools. At first glance, in comparison with the classic MCC, the work seems dusty and uncomplicated. And from skeptics follows a series of criticisms that for similar tools you can look at the part in color during analysis or repaint it in garages.

Imagine a person in a new car, riding through disassemblies or garages. I'm not talking about getting the part found in color, about independent reinforcing work during replacement, about the place of work. And what and how garage painters paint is generally unknown. But since we are talking about savings, it means that we should cut back on everything. An inexperienced person simply does not understand that in order to straighten dents, one must have skill and expensive equipment.

– And what about the PDR tool market itself? How is it segmented and arranged?

- At the moment, the Av-Tool tool occupies a leading position in the Russian market. This is due, firstly, to the lack of competitors among domestic manufacturers and, secondly, to high prices for American and German counterparts. The Chinese noname doesn't bother us at all, because they haven't figured out the PDR technology yet. They copy, but in reality it turns out to be completely illiquid and defective: steel for hooks is used in the wrong alloys, it is not so hardened, not calibrated. The components of adhesive systems, for example mini-lifters, are also very similar in appearance, but do not have the necessary stroke.

The PDR tool market is very limited and intended for a narrow circle of specialists. Classic bodywork is performed in any yard, but there are no masters for paintless dent removal in some Russian cities at all. Accordingly, the first category will always need supplies of consumables, and the second - from case to case. Volumes are incomparable.

- I assume that the crisis somehow shook your sales in the Russian market. Have any steps been taken to compensate for these losses?

- Yes, there was a small fall, which led us to the conclusion that a serious airbag might come in handy next time. In order to neutralize such unpleasant scenarios in the future, it was decided to reorient our marketing activities abroad. In Europe, there has long been a great interest in the Av-Tool brand. Through partners, we have represented our instrument at the leading trade fairs in the region. Most of our European colleagues are very interested in promoting the brand, since the Russian tool, which is not inferior in quality, allows them to significantly dilute their portfolio of German and American brands.

Recently, we have successfully opened our online store in England, enlisted the support of colleagues in the United States, and received distribution offers from the Netherlands and Portugal. We establish a clear pricing policy that is understandable to all interested parties and conduct a transparent business. This allows us, along with distributors in the region, to independently trade our own products. Partners sell certain volumes of the instrument, and we, in turn, also increase overall sales.

There are also proposals for an exclusive partnership, the so-called representation in some EU countries. But here lies the political problem. The representative must close the region for us in volumes, and this is production and logistics planning. If this is not the case, then by giving exclusive rights to one hand, we risk becoming hostages of this seller. And we, as I said, are trying to minimize the risks. Distribution is more relevant.

– What are your plans for participation in international exhibitions?

- We will not exhibit in Russia, the client base is limited and narrowly focused, the competition is not global. This year, our partners are exhibiting with two stands in Manchester, and next year we are going to go to the USA ourselves.

– Where and from what do you produce the Av-tool?

– We produce here in Aprelevka with a full cycle. Unfortunately, some parts have to be imported, such as knobs. In Russia, no one makes such "semi-finished products", but for us, with small volumes, it is unprofitable to organize a foundry. But the high-quality installation of rotary fittings and finishing is already our work. Sometimes we still limit ourselves to buying only the mechanisms themselves, and we finish the handles ourselves, but this only applies to some models of the instrument.

It is regrettable to say, but we use imported metal. The problem is not in quality, but in the structure of the economy. I won’t name the steel grade, but I’ll just say that the Russian industry does not sell calibrated steel of this quality at retail for business. If you directly contact the metallurgical plant, then it can be produced, but then you need to order tons and prepaid. Therefore, no matter how much we would like to reduce the final cost for Russian consumers, we are unable to do this due to the above reasons.

– Our readers are wondering where to start, how to plan your own PDR business? Are there any common grounds?

- First of all, it should be indicated that it will be: a private family business or additional services at an existing car repair enterprise. In the first case, you will need a clean, bright room for one or two cars. You should also enlist the support of a partner, because it is difficult to perform a lot of reinforcing work alone. This option is suitable for regions where people are used to working with clients on an individual basis.

The second option concerns megacities and regional centers with a guaranteed load of the service. There is a different audience here, so it is more logical to promote this service at the service station. If you are not the owner of the service, but just a person who wants to master this profession, then in a big city it is easier to work as part of an outsourced mobile team than in your own box. Owners of expensive cars over a million rubles will not go to remove dents in some garages.

In any case, the first step is to educate yourself or a specialist. The main questions I get asked over the phone are: “Where are the guarantees that you will teach me?” and “Will I successfully remove dents after 2 weeks of training?” I answer: “And where are the guarantees that you want to learn?” The questions are about motivation. After completing the training course, the newly minted specialist should spend as much of his time on consolidating the skills acquired during the training.

Thanks to videos on the Internet and good installation, people get the impression that PDR repair is 10 minutes of simple operations with shiny tools, and voila - the car is ready. A calculator immediately works in the viewer's head. If they earned, relatively speaking, 3,000 rubles in 30 minutes and did not even get dirty, then in a day they can earn the same amount, multiplied first by 2, and then by 8 working hours. The result is a fabulous figure, and 6 hours of real work remain outside the brackets. You need to soberly assess the situation, and prepare yourself for hard painstaking work.

– At the beginning of the conversation, you said that clients often misjudge the complexity of PDR work, demanding unreasonable discounts. How is the cost of services generally calculated, and how is pricing regulated? What should a business organizer take as a basis when forming a price list?

- Indeed, in this matter we educate our students, give the basics of the tariff scale. But still, it varies from region to region, depends on the level of SRT. In our case, it is impossible to establish the cost of a specific standard hour, since all dents are different. The dent can be large, but at the same time it is located in an open place, and there are also minor hail damage, for which you need to disassemble the entire roof. How to evaluate it? How to graduate repairs using hooks, glue systems, pumps?

Usually we base on the prices of classic repairs and partially, depending on the conditions, tie the cost to it. But some skeptics are still unhappy. The fact is that they do not see consumables, cameras, spray guns, etc. Accordingly, they conclude that under such circumstances, repairs should cost 5 times cheaper.

This is generally an indecent phenomenon - to count other people's money and evaluate someone else's work. When I go to a computer technician, I don't pay him because he came without wrenches. Try to evaluate the work of a doctor, teacher or engineer without the relevant knowledge. Just think, they sit on chairs all day, writing papers. Ridiculous, but so is our case. A person invests a lot of money in himself, in his business. He buys an expensive tool, along the way he must feed himself and his loved ones, pay rent, taxes. And the client is “amazed” by the raised price, absurd.

All this the master is obliged to convey to his clients. And only after that they will stop counting his money and think about themselves. I note that competent and transparent costing plays a huge role. You need to work closely with the machine and the client at the acceptance, draw up the correct documents, correctly assess the damage. This is conducive to trust.

In conclusion, I will note to skeptics and critics that PDR technology, as we have repeatedly told in the KUZOV magazine, came from car factories, including Soviet ones. Today, PDR masters, people I personally know, work at AMG, Porsche Macan, VAG factories. Their salaries are on average 40 euros per hour for a 10-hour working day. It happens that due to a malfunction on the conveyor, robots leave minor dents in certain places on the bodies of manufactured cars. It is unprofitable to stop and reconfigure the line, and dents are removed after the machine has left the belt by paintless dent removal specialists. To understand the scale of this industry, it should be mentioned that at the Porsche Macan plant, PDR specialists work in 3 shifts, each with 40 people. We recently sent quite a few tools to Bentley. The technology is in great demand.

Minor body damage resulting from impacts with small objects (hail, stones, etc.) can cause big problems for the car owner. But there is a way out. The use of Hotbox HTR-02 and Dent devices gives excellent results without the use of putty or painting, leaving no trace of past defects. What's more, it's a great business idea!

Induction hail dent remover Hotbox HTR-02

Hotbox HTR-02 is an induction body rectifier. It was invented in Switzerland. Now he has penetrated virtually all corners of the globe, becoming an indispensable assistant and a real boon for car repairmen! This do-it-yourself paintless dent removal tool allows you to quickly get rid of various types of dents. Moreover, without complex and expensive work with the body, which previously included straightening, grinding and painting. Now you can forget about all the costly inconveniences. Thanks to Hotbox HTR-02, your car body can be perfectly smooth in just a few seconds!

The main advantages of the Hotbox HTR-02 are as follows:

- Very quickly allows you to get rid of unwanted body defects.

- Now you do not need to remove individual parts of the car to fix damage from the inside. All necessary manipulations are carried out from the outside, while without the laborious dismantling of the damaged element.

- Allows you to work in places where it is simply impossible to correct deformations in other ways.

- Simplicity and clarity in operation. Even a beginner can work with the device.

- Compactness, light weight (about 3 kg for the whole set), convenient shape of the device, which makes it easy to manipulate it even in the most inconvenient places.

- The special design allows you to hold the device clearly above the dent, avoiding sliding along the body and unwanted displacement of the unit to the side.

- Absolutely does not damage the surface during the restoration work.

- Does not require additional costs and the purchase of auxiliary consumables.

- Fast self-sufficiency (the cost of the device is $ 1640) and profit already after 2 months of work!

A few words about the operation of Hotbox HTR-02

The main impact on the damage occurs due to the directed highly efficient heating of the metal, which, as a result of such a process, acquires a special plasticity, and under the influence of physical forces instantly straightens itself.

On this device, you can adjust the power and time of exposure, taking into account the area and the difficulty of the work being done to correct dents. By time, you can select a pulse duration from 0.5 to 2.5 seconds. Power is regulated in five modes in steps of 20%: from 20% to 100%. In turn, experienced craftsmen advise to be quite careful when working at high powers: with a long exposure to the surface, you can damage the paint layer on the car by simply spitting it out. So it is better to straighten the dent in two or three passes than to save a few seconds at the cost of damaging the surface.

Thanks to a convenient nozzle, the straightening process is carried out very conveniently and does not cause the slightest discomfort to the master. Naturally, the low weight of the device and its compactness adds additional advantages, positively affecting the maneuverability of work and mobility. In a word, if specialized specialists would undertake to improve this unit, they would puzzle over what exactly to do better for a very long time!

How to work with him?

The head of the inductor must be placed at the edge of the dent at an angle of 90 degrees to the surface. Then we turn on the device, hold it for about a second and observe the result, simultaneously checking the level of heating of the metal. To completely correct small and medium-sized defects, you need to make cross-shaped movements with the device from one edge of the dent to the other. As you already understood, the main danger is burning paint at the site of damage, which is an extremely undesirable side effect and entails additional financial costs. Repeat approaches only after the surface has completely cooled.

What types of damage can be repaired

These include:

- Hail dents.

- Defects caused by falling objects from a great height.

- Consequences of a minor accident.

- Damage due to bad parking.

- Negligence of passers-by, intentionally (an act of vandalism) or through negligence hooked your car with a trolley, bag or other hand luggage.

DENT - car dent removal tool

DENT technology is a whole package for paintless dent removal. Often referred to as PDR (Paintless Dent Repair), it also implies highly effective dent removal. As in the case of Hotbox HTR-02, there is no need to paint damage to the body after the defect is eliminated, which significantly saves the customer's money.

How does DENT work and what are its benefits?

The DENT kit includes paintless dent removal tools. It consists of levers of a special configuration, which, through the technological holes of the car, exert directed pressure on the dent. Along the way, it is affected from the outside thanks to a special pulling technology. The work takes a fairly short period of time (from 15 minutes to one hour) and leads to an excellent result: often the place of damage after applying DENT technology simply cannot be distinguished from neighboring parts of the body!

DENT is not afraid of dents of varying depth and complexity on any part of the car. Thanks to the use of internal adhesive-based suction cups and special micro-lifts, even the deepest lesions are pulled out without the use of special forces. The advantage of the technology over the Hotbox HTR-02 is that it can deal with much larger areas of increased complexity.

How much does paintless dent removal cost?

If you decide to start your own business of repairing various damage to car bodies, then you should know that this is a very profitable and profitable business!

Once spent on DENT or Hotbox HTR-02 devices, you simply forget about any further expenses. Given the durability of the devices, as well as the potential number of customers, the final profit can amaze any fantasy!

The average market price for dent removal varies depending on the complexity of the damage. Often the cost of repairs is from $10 to $1000. If you have your own premises (the most ordinary garage will do) and an average workload of 2-5 cars per day. This means that after the payback of the device, monthly earnings can easily exceed the cost of equipment in less than 2 months. The benefits of starting your own business are obvious here.

You should not even think about it: with a small investment and a few days spent on self-study, you will become the owner of a highly profitable business that will become the basis of your financial well-being for many years to come!

WHY(PDR)?

Today, there are a huge number of cars in the world and their number is steadily growing from year to year, 70% of cars have minor damage on the body: from careless parking, careless opening of doors, weather disasters (hail, falling icicles, branches, etc. .) - all these damages give car owners a lot of trouble and no less serious material costs! With the help of paintless dent repair (PDR) technology, you can successfully and very effectively cope with this task, and these are not "beautiful words", but a reality that has been used all over the world for many years! Therefore, today all over the world, and in our country in particular, there is a huge shortage of professional technicians for Paintless Dent Removal (PDR).WHAT IS THE ADVANTAGE OF PAINT FREE DENT REPAIR (PDR) TECHNOLOGY

- 1. Very short repair time (from 20 minutes to 4 hours).

- 2. Repair costs are approximately 40% lower than traditional repair methods.

- 3. The car does not go into the category of painted, which favorably affects its sale value.

- 4. Mobility (you can make repairs almost anywhere).

- 5. Environmental friendliness.

- 6. No consumables - high profitability.

- 7. Fast return on investment.

WHERE TO BEGIN?

Suppose you have collected initial information about the technology of paintless dent repair and seriously intend to get an interesting and highly paid profession, now you need to decide on the choice of a training organization, this is an extremely serious issue, since your further success in this field will depend on this or you will become a real a professional, or a low-level master, or you won’t be able to work at all! In order not to make a mistake with the choice, look at the real works of the master who will teach you, at the reviews of clients who turned to this master, as well as at the reviews of students who previously studied at the center of your choice - the benefit of the Internet allows you to do this ! And remember, it will not be a beautiful advertisement with links to Western companies that will train you, but a single specialist, and the final result will depend on what he knows himself, on his ability to convey information to the listener, to see and correct mistakes in time! Step number two is buying a tool! Fortunately, today there is a choice, you just have to monitor prices and choose the instrument you like, if you are not sure of your choice, seek help from professionals who can help you choose the right instrument! Step number three is to find a suitable room, usually a box, 4m by 6m in size. Step number four is a competent advertising campaign, the key to future success, everything is suitable here: outdoor advertising, business cards, booklets, flyers, and, of course, the Internet!HOW TO IMPLEMENT?

The main activity of our company is the repair of paintless dents (PDR), we are also engaged in the development, production and sale of the professional PDR tool "AV-TOOL". instrument of the year"Students who have been trained at AV-MASTERS work effectively in Russia, the CIS countries, Europe and America (see section). We maintain constant contact with all our students and provide comprehensive support! Turning to AV-MASTERS "You are guaranteed to master the technology of repairing dents without painting, receive an international specialist diploma and subsequent comprehensive support, our specialists will help you choose the kit you need for the operation of the equipment, and answer all your questions!Have you ever paid attention to the number of "crumpled" cars? According to statistics, about 80% of cars have ever been in an accident, albeit a small one. But a significant part of minor damage is not repaired by car owners, mainly due to the high cost of the service or the lack of a normal service in the city. Try, being in a traffic jam, to count the number of cars with obvious dents on the body. You will be pleasantly surprised. They are all future customers of the service for removing dents without painting the car body.

The technology for removing dents without painting the body was first used by the German company Karosseriebau Nuessle and its owner Erich Nüssle back in 1972. It turned out that almost any dent can be removed without problems if skillful hands and a special set of DOL tools are applied to the job. But the company did not immediately dare to distribute its brand. And only 20 years later, in 1996, the company decided to enter the market under the brand name Nussle Spezialwerkzeuge - Nussle special tools. The company also actively engaged in the sale of training courses on the technology of removing dents without painting the car body.

This technology has become widespread due to:

- Dent removal speed. Complex body defects can be repaired in hours, while simple dents can be removed in less than an hour. While normal repairs take at least 2 days, even with the slightest damage to the body;

- The repaired car is ready for full operation immediately after the removal of the dent;

- Repair quality. After removing the dent, the factory paintwork is preserved. In the end, it is possible to avoid getting the car into the category of “painted” or “broken”, which allows you to sell the car more profitably;

- Repair price. Removing a dent will cost two to three times cheaper than with conventional body straightening followed by painting.

The only clarification is that only a certain category of dents is subject to repair. If during an accident the car was seriously damaged, and the dent turned out to be “pointed”, then it will not work to repair the body using this technology.

What equipment to choose for removing dents without painting a car

The starter set of equipment for removing dents includes special hooks (about 13 sizes), an adhesive system, a mini-llama and accessories: a mini-lifter, caps, glue remover, a mounting spatula, an expander pad, etc. A complete set of new tools will cost about 75 thousand rubles.

How to Start a Paintless Dent Removal Business

The provision of dent repair services using this technology requires certain professional skills. It is very difficult to learn this on your own. Today, there are many organizations and individuals who are ready to teach a person the technology of paintless dent removal for a fee. The cost of a 7-day course costs about 40 thousand rubles. Most courses are held in Moscow. If you find another person, that is, organize a group, then training is provided at a discount. The cost usually includes accommodation for the entire period of study.

Training in the technology of paintless dent removal takes place in a fairly intensive mode with practical examples of how to remove defects. The most important thing in training is to learn how to correctly see the defect with the help of lamps and not lose sight of the tool. In another way, such a skill is called - setting the hand. If for the entire period of study the student has not acquired the necessary skills for various reasons, then he is offered to take additional courses.

How much money is needed to start a business

Ultimately, investments in opening a business can amount to 100 - 150 thousand rubles, given that you already have a ready-made premises. If the rented or own premises require repair, then the start-up costs will be slightly higher. To provide services for the removal of dents, it is enough to rent a room with an area of 30 m2 with good lighting and heating.

According to entrepreneurs, with the right promotion of the business, there will be no end to customers. This is especially true for small towns, where you are the only such service. A lot of requests from the fair sex, especially novice drivers.

How much can you earn by removing dents

As for income, the alignment is as follows. The cost of the service is in the range from 1500 to 5000 rubles, depending on the size of the dent and the complexity of the work. For an 8-hour working day, depending on the complexity of the damage, one master can service up to 5-6 cars. With an average service price of 2 thousand rubles, the income will be 10-12 thousand rubles per day. Monthly revenue will be 300 thousand rubles or more.

Moreover, this is practically a net income if you are engaged in this business on your own (without involving hired labor). Renting 30m2 will amount to a maximum of 15 thousand rubles. per month, taxes under the simplified system of 6% of gross income - 18 thousand rubles.

Do I need permission to open a dent removal business without painting a car?

To provide services legally, it is enough to register individual entrepreneurship at the local IFTS. Registration will take no more than 7 days and no more than 1 thousand rubles will be spent. Taxation system, as already described above, there may be a simplified taxation system (6 or 15%), or you can buy a patent.

A significant disadvantage of this business is a strong dependence on staff. It's one thing if you personally have been trained and provide these services yourself. But this is no longer a business, but a real “work for yourself”. You will plow every day from 8:00 to 20:00, and earn big money with your physical labor. Another option - you hired an employee, paid for his training, and after working for a couple of months and gaining experience, he successfully quit and opened his own service. As a way out of the situation - the conclusion of an agreement with the employee for working off after graduation. However, the legislation provides that an employee can quit earlier than the period established by the contract, simply by paying the employer the cost of the costs incurred for his training. Therefore, in this case, it is important, on the one hand, to find qualified and honest workers, and on the other hand, not to “spawn” competitors to your business with your own hands.

Which OKVED to indicate when registering a business for removing dents without painting a car

The all-Russian classifier of types of activity for a dent removal workshop does not provide a separate code. Therefore, when preparing an application for registration of an individual entrepreneur, indicate OKVED 50.20.3 (other types of vehicle maintenance services).

What documents are needed to open a car repair shop

To organize a business for the removal of dents without painting the car body and the subsequent activities of the company, the following documents are required:

- Certificates of registration of individual entrepreneurs and papers confirming that you are a taxpayer.

- Room lease agreement.

- Permits of the district administration, SES and fire inspection.

- Agreements for garbage collection, maintenance of ventilation systems, etc.

Particular attention should be paid to the labor contract with the workshop employee. If you were involved in his training (paying for courses, organizing practical classes, etc.), be sure to make a clause on compensation for these expenses when the employee (having received the necessary experience at your expense) decides to quit.

Which taxation system to choose for business registration

When preparing an application for choosing a taxation regime for this area of commercial activity, you can indicate: a patent and a simplified tax system. The first option is much more convenient, but is not used in all regions of the country (local authorities decide this issue). With a simplified system, you can pay 6% of the workshop's revenue or 15% of its profits.

Vehicle damage repair technology

Repair work to remove dents includes the following steps:

- Determination of the nature of damage (it is not always possible to carry out repairs without subsequent painting of the body).

- A method is chosen to eliminate the defect: the first option allows you to “pull out” the metal from the outside, in the second case, you need to use special tools and apply pressure on the inside of the damaged area.

A good master performs the above procedures at such a level that after repair it is almost impossible to determine where the dent was.

Popular

- Profitable business: how to open a marriage agency

- Paving slab production business plan from a to z How to open a paving slab manufacturing business

- Franchise cost and cost of ownership

- How to open a recruitment agency

- Typical mistakes when renting premises for a store

- How to get a license to trade in flowers

- Classification of business centers and shopping centers

- Potato growing business: sales features and profit

- New projects in Russia to be led by Dmitry Sokov New projects in Russia will make EuroChem a world leader

- Where Nordman tires are made