Multicolor diode. The use of LEDs in electronic circuits

Your region:

Pickup from the office

Pickup from the office in Moscow

- The office is located a 5-minute walk from Taganskaya metro station, at 6, Bolshoy Drovyanoy lane.

- If placed before 15:00 on a weekday, the order can be picked up after 17:00 on the same day, otherwise - the next weekday after 17:00. We will call and confirm the readiness of the order.

- You can receive an order from 10:00 to 21:00 seven days a week after it is ready. The order will wait for you 3 working days. If you want to extend the storage period, just write or call.

- Write down your order number before visiting. It is required upon receipt.

- To get to us, present your passport to the entrance, say that you are in Amperka, and take the elevator to the 3rd floor.

- is free

Delivery by courier in Moscow

- We deliver the next day when ordering before 20:00, otherwise - the next day.

- Couriers work from Monday to Saturday, from 10:00 to 22:00.

- You can pay for the order in cash upon receipt or online when placing an order.

- 250 ₽

Delivery to PickPoint

- pickpoint.

- You can pay for the order in cash upon receipt or online when placing an order.

- 240 ₽

Delivery by courier in St. Petersburg

Delivery by courier in St. Petersburg

- We deliver every other day if ordered before 20:00, otherwise - in two days.

- Couriers work from Monday to Saturday, from 11:00 to 22:00.

- When agreeing on an order, you can choose a three-hour delivery interval (the earliest is from 12:00 to 15:00).

- You can pay for the order in cash upon receipt or online when placing an order.

- 350 ₽

Delivery to PickPoint

- Delivery to a pickup point is a modern, convenient and fast way to receive your order without calling and catching couriers.

- Pickup point is a kiosk with a person or an array of iron boxes. They are put in supermarkets, office centers and other popular places. Your order will be at the point you select.

- You can find the point closest to you on the PickPoint map.

- Delivery time - from 1 to 8 days depending on the city. For example, in Moscow it is 1-2 days; Petersburg - 2-3 days.

- When the order arrives at the pickup point, you will receive an SMS with a code to receive it.

- At any convenient time within three days, you can come to the point and use the code from SMS to receive an order.

- You can pay for the order in cash upon receipt or online when placing an order.

- Delivery cost - from 240 rubles, depending on the city and size of the order. It is calculated automatically during checkout.

- 240 ₽

Delivery to the pickup point

Delivery to PickPoint

- Delivery to a pickup point is a modern, convenient and fast way to receive your order without calling and catching couriers.

- Pickup point is a kiosk with a person or an array of iron boxes. They are placed in supermarkets, office centers and other popular places. Your order will be at the point you select.

- You can find the point closest to you on the PickPoint map.

- Delivery time - from 1 to 8 days depending on the city. For example, in Moscow it is 1-2 days; Petersburg - 2-3 days.

- When the order arrives at the pickup point, you will receive an SMS with a code to receive it.

- At any convenient time within three days, you can come to the point and use the code from SMS to receive an order.

- You can pay for the order in cash upon receipt or online when placing an order.

- Delivery cost - from 240 rubles, depending on the city and size of the order. It is calculated automatically during checkout.

Post office

- Delivery is carried out to the nearest post office. branches in any locality Russia.

- The tariff and delivery time are dictated by Russian Post. On average, the waiting time is 2 weeks.

- We transfer the order to the Russian Post within two business days.

- You can pay for the order in cash upon receipt (cash on delivery) or online when placing an order.

- The cost is calculated automatically during the order and should average about 400 rubles.

Everyone is familiar with LEDs. Without them it is simply unthinkable. modern technology. These are LED lights and lamps, indication of operating modes of various household appliances, backlighting of screens of computer monitors, TVs and many other things that you can’t immediately remember about. All of these devices contain LEDs in the visible range of radiation of various colors: red, green, blue (RGB), yellow, white. Modern technologies allow you to get almost any color.

In addition to visible light emitting diodes, there are infrared and ultraviolet light emitting diodes. The main area of application of such LEDs is automation and control devices. Enough to remember. If the first remote control models were used exclusively to control TVs, now they control wall-mounted heaters, air conditioners, fans and even kitchen appliances, such as multi-cooker pots and bread makers.

So what is an LED?

In fact, it is not much different from the usual one - all the same p-n junction, and all the same basic property of one-way conduction. As learning p-n transition, it turned out that in addition to unilateral conductivity, this very transition has several additional properties. In the course of the evolution of semiconductor technology, these properties have been studied, developed and improved.

A great contribution to the development of semiconductors was made by the Soviet radio physicist (1903 - 1942). In 1919, he entered the famous and still known Nizhny Novgorod radio laboratory, and from 1929 he worked at the Leningrad Institute of Physics and Technology. One of the activities of the scientist was the study of a weak, barely noticeable, glow of semiconductor crystals. It is on this effect that all modern LEDs work.

This weak glow occurs when current is passed through the p-n junction in the forward direction. But at present, this phenomenon has been studied and improved so much that the brightness of some LEDs is such that you can simply go blind.

The color gamut of LEDs is very wide, almost all colors of the rainbow. But the color is obtained not at all by changing the color of the LED housing. This is achieved by adding dopants to the p-n junction. For example, the introduction of a small amount of phosphorus or aluminum makes it possible to obtain colors of red and yellow shades, while gallium and indium emit light from green to blue. The housing of the LED can be transparent or matte, if the housing is colored, then this is just a light filter corresponding to the color of the glow of the p-n junction.

The color gamut of LEDs is very wide, almost all colors of the rainbow. But the color is obtained not at all by changing the color of the LED housing. This is achieved by adding dopants to the p-n junction. For example, the introduction of a small amount of phosphorus or aluminum makes it possible to obtain colors of red and yellow shades, while gallium and indium emit light from green to blue. The housing of the LED can be transparent or matte, if the housing is colored, then this is just a light filter corresponding to the color of the glow of the p-n junction.

Another way to obtain the desired color is the introduction of a phosphor. A phosphor is a substance that produces visible light when exposed to other radiation, even infrared. A classic example of this is fluorescent lamps. In the case of LEDs, a white color is obtained by adding a phosphor to a blue glow crystal.

To increase the radiation intensity, almost all LEDs have a focusing lens. Often, the end of a transparent body, which has a spherical shape, is used as a lens. In infrared LEDs, the lens sometimes looks opaque, smoky gray. Although in Lately infrared LEDs are produced simply in a transparent case, these are the ones used in various remote controls.

Bicolor LEDs

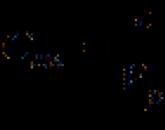

Also known to almost everyone. For example, a charger mobile phone: While charging, the indicator lights up red, and when charging is complete, it turns green. This indication is possible due to the existence of two-color LEDs, which can be different types. The first type is three-pin LEDs. One housing contains two LEDs, for example, green and red, as shown in Figure 1.

Figure 1. Wiring diagram for a two-color LED

The figure shows a fragment of a circuit with a two-color LED. In this case, a three-pin LED with a common cathode is shown (there are also common anodes) and its connection to. In this case, you can turn on either one or the other LED, or both at once. For example, it will be red or green, and when you turn on two LEDs at once, you get yellow. If at the same time using PWM modulation to adjust the brightness of each LED, you can get several intermediate shades.

In this circuit, you should pay attention to the fact that the limiting resistors are included separately for each LED, although it would seem that one can be dispensed with by including it in a common output. But with this inclusion, the brightness of the LEDs will change when one or two LEDs are turned on.

What voltage is needed for the LED This question can be heard quite often, it is asked by those who are not familiar with the specifics of the operation of the LED or simply by people who are very far from electricity. At the same time, it is necessary to explain that the LED is a device controlled by current, and not by voltage. You can turn on the LED at least 220V, but the current through it should not exceed the maximum allowable. This is achieved by connecting a ballast resistor in series with the LED.

But still, remembering the voltage, it should be noted that it also plays a big role, because the LEDs have a large forward voltage. If for a conventional silicon diode this voltage is of the order of 0.6 ... 0.7 V, then for an LED this threshold starts from two volts and above. Therefore, from a voltage of 1.5V, the LED cannot be lit.

But with this inclusion, meaning 220V, one should not forget that the reverse voltage of the LED is quite small, no more than a few tens of volts. Therefore, special measures are taken to protect the LED from high reverse voltage. The easiest way is the opposite - parallel connection of a protective diode, which may also not be very high-voltage, for example KD521. Under the influence of alternating voltage, the diodes open alternately, thereby protecting each other from high reverse voltage. The circuit for switching on the protective diode is shown in Figure 2.

Figure 2. Wiring diagram parallel to LED protective diode

Bicolor LEDs are also available in a package with two terminals. The change in the color of the glow in this case occurs when the direction of the current changes. A classic example is the indication of the direction of rotation of a DC motor. In this case, one should not forget that a limiting resistor is necessarily connected in series with the LED.

Recently, a limiting resistor is simply built into the LED, and then, for example, on the price tags in the store they simply write that this LED is 12V. Also, flashing LEDs are marked by voltage: 3V, 6V, 12V. There is a microcontroller inside such LEDs (it can even be seen through a transparent case), so any attempts to change the blinking frequency do not give results. With this marking, you can turn on the LED directly to the power supply for the specified voltage.

Developments of Japanese radio amateurs

It turns out that amateur radio is being practiced not only in the countries of the former USSR, but also in such an “electronic country” as Japan. Of course, even a Japanese ordinary radio amateur cannot create very complex devices, but individual circuit solutions deserve attention. Whether it is not enough in what scheme these decisions can be useful.

Here is an overview of relatively simple devices that use LEDs. In most cases, control is carried out from microcontrollers, and there is no getting around this. Even for a simple circuit, it is easier to write a short program and solder the controller in a DIP-8 package than to solder several microcircuits, capacitors and transistors. It is also attractive that some microcontrollers can work without attachments at all.

Dual color LED control circuit

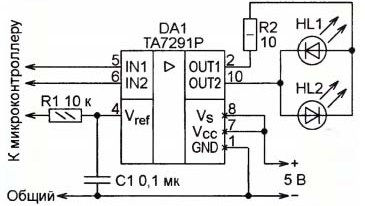

An interesting scheme for controlling a powerful two-color LED is offered by Japanese radio amateurs. More precisely, two powerful LEDs with a current of up to 1A are used here. But, it must be assumed that there are also powerful two-color LEDs. The circuit is shown in Figure 3.

Figure 3. Driving scheme for a powerful two-color LED

The TA7291P chip is designed to control small power DC motors. It provides several modes, namely: forward rotation, reverse rotation, stop and braking. The output stage of the microcircuit is assembled according to a bridge circuit, which allows you to perform all the above operations. But it was worth putting in some imagination, and here you are, the microcircuit has a new profession.

The logic of the microcircuit is quite simple. As you can see in Figure 3, the microcircuit has 2 inputs (IN1, IN2) and two outputs (OUT1, OUT2), to which two powerful LEDs are connected. When the logic levels at inputs 1 and 2 are the same (no matter 00 or 11), then the output potentials are equal, both LEDs are off.

At different logic levels at the inputs, the microcircuit works as follows. If one of the inputs, for example, IN1 has a low logic level, then the output OUT1 is connected to a common wire. The cathode of the LED HL2 through the resistor R2 is also connected to a common wire. The voltage at the output OUT2 (if there is a logical unit at the input IN2) in this case depends on the voltage at the input V_ref, which allows you to adjust the brightness of the HL2 LED.

In this case, the voltage V_ref is obtained from PWM pulses from the microcontroller using an integrating circuit R1C1, which adjusts the brightness of the LED connected to the output. The microcontroller also controls the inputs IN1 and IN2, which allows you to get a wide variety of shades of light and LED control algorithms. The resistance of the resistor R2 is calculated based on the maximum allowable current of the LEDs. How to do this will be described below.

Figure 4 shows the internal structure of the TA7291P chip, its block diagram. The circuit is taken directly from the datasheet, so it shows an electric motor as a load.

Figure 4

By block diagram it is easy to trace the current paths through the load and how the output transistors are controlled. Transistors are switched on in pairs, diagonally: (upper left + lower right) or (upper right + lower left), which allows you to change the direction and speed of the motor. In our case, light one of the LEDs and control its brightness.

The lower transistors are controlled by signals IN1, IN2 and are simply designed to turn the bridge diagonals on and off. The top transistors are controlled by the Vref signal, they regulate the output current. The control circuit, shown simply as a square, also contains a protection circuit against short circuits and other contingencies.

In these calculations, as always, Ohm's law will help. Let the initial data for the calculation be as follows: supply voltage (U) 12V, current through the LED (I_HL) 10mA, the LED is connected to a voltage source without any transistors and microcircuits as an on indicator. LED voltage drop (U_HL) 2V.

Then it is quite obvious that the limiting resistor will have a voltage (U-U_HL), - the LED itself “ate” two volts. Then the resistance of the limiting resistor will be

R_o = (U-U_HL) / I_HL = (12 - 2) / 0.010 = 1000(Ω) or 1KΩ.

Do not forget about the SI system: voltage in volts, current in amperes, result in ohms. If the LED is turned on by a transistor, then in the first bracket, the voltage of the collector-emitter section of the open transistor should be subtracted from the supply voltage. But, as a rule, no one ever does this, accuracy to hundredths of a percent is not needed here, and it will not work due to the spread of the parameters of the parts. All calculations in electronic circuits give approximate results, the rest has to be achieved by debugging and tuning.

Tricolor LEDs

In addition to two-color ones, they have recently become widespread. Their main purpose is decorative lighting on stages, at parties, at New Year's celebrations or at discos. Such LEDs have a package with four terminals, one of which is a common anode or cathode, depending on the specific model.

But one or two LEDs, even three-color ones, are of little use, so you have to combine them into garlands, and use all kinds of control devices, which are most often called controllers, to control the garlands.

Assembling garlands of individual LEDs is boring and uninteresting. Therefore, in last years the industry began to produce, as well as tapes based on tri-color (RGB) LEDs. If one-color tapes are produced for a voltage of 12V, then the operating voltage of three-color tapes is often 24V.

LED strips are marked by voltage, because they already contain limiting resistors, so they can be connected directly to a voltage source. Sources for are sold in the same place as the tapes.

Special controllers are used to control three-color LEDs and strips, to create various lighting effects. With their help, it is possible to simply switch LEDs, adjust brightness, create various dynamic effects, as well as draw patterns and even paintings. The creation of such controllers attracts many radio amateurs, naturally those who know how to write programs for microcontrollers.

With the help of a three-color LED, you can get almost any color, because the color on the TV screen is also obtained by mixing only three colors. Here it is appropriate to recall another development of Japanese radio amateurs. Its schematic diagram is shown in Figure 5.

Figure 5. Wiring diagram for a three-color LED

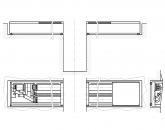

Powerful 1W tri-color LED contains three emitters. With the values of the resistors indicated in the diagram, the color of the glow is white. By selecting the values of the resistors, some change in shade is possible: from cold white to warm white. In the author's design, the lamp is designed to illuminate the car interior. Should they (Japanese) be in sorrow! In order not to worry about observing the polarity, a diode bridge is provided at the input of the device. The device is mounted on a breadboard and is shown in Figure 6.

Figure 6. Development board

The next development of Japanese radio amateurs is also of an automotive nature. This device for backlighting the number, of course, on white LEDs is shown in Figure 7.

Figure 7. Scheme of the device for backlighting the number plate on white LEDs

The design uses 6 powerful superbright LEDs with a maximum current of 35mA and a luminous flux of 4lm. To increase the reliability of the LEDs, the current through them is limited to 27mA using a voltage stabilizer microcircuit, included in the current stabilizer circuit.

LEDs EL1 ... EL3, resistor R1 together with the DA1 chip form a current stabilizer. A stable current through the resistor R1 maintains a voltage drop of 1.25V across it. The second group of LEDs is connected to the stabilizer through exactly the same resistor R2, so the current through the group of LEDs EL4 ... EL6 will also be stabilized at the same level.

Figure 8 shows a converter circuit for powering a white LED from one galvanic cell with a voltage of 1.5V, which is clearly not enough to ignite the LED. The converter circuit is very simple and is controlled by a microcontroller. In fact, the microcontroller is with a pulse frequency of about 40 kHz. To increase the load capacity, the microcontroller outputs are connected in pairs in parallel.

Figure 8

The scheme works as follows. When the outputs PB1, PB2 are low, the outputs PB0, PB4 are high. At this time, the capacitors C1, C2 through the diodes VD1, VD2 are charged up to about 1.4V. When the state of the controller outputs is reversed, the sum of the voltages of the two charged capacitors plus the battery voltage will be applied to the LED. Thus, almost 4.5V will be applied to the LED in the forward direction, which is quite enough to light the LED.

Such a converter can be assembled without a microcontroller, just on a logic chip. Such a scheme is shown in Figure 9.

Figure 9

On the element DD1.1, a rectangular oscillation generator is assembled, the frequency of which is determined by the ratings R1, C1. It is at this frequency that the LED will flash.

When the output of the element DD1.1 is high, the output of DD1.2 is naturally high. At this time, the capacitor C2 is charged through the diode VD1 from the power source. The charge path is as follows: plus the power source - DD1.1 - C2 - VD1 - DD1.2 - minus the power source. At this time, only battery voltage is applied to the white LED, which is not enough to light the LED.

When the level at the output of the element DD1.1 becomes low, a high level appears at the output of DD1.2, which leads to the blocking of the diode VD1. Therefore, the voltage across the capacitor C2 is added to the battery voltage and this amount is applied to the resistor R1 and the LED HL1. This sum of voltages is enough to turn on the HL1 LED. Then the cycle repeats.

How to test an LED

If the LED is new, then everything is simple: the terminal that is slightly longer is positive or anode. It is he who must be included to the plus of the power source, of course, not forgetting about the limiting resistor. But in some cases, for example, the LED was soldered from the old board and its leads are of the same length, a continuity is required.

Multimeters in such a situation behave somewhat incomprehensibly. For example, a DT838 multimeter in semiconductor test mode can simply slightly illuminate the LED being tested, but an open is shown on the indicator.

Therefore, in some cases it is better to check the LEDs by connecting them through a limiting resistor to the power source, as shown in Figure 10. The resistor value is 200 ... 500 Ohm.

Figure 10. LED test circuit

Figure 11. Sequential connection of LEDs

It is not difficult to calculate the resistance of a limiting resistor. To do this, add the forward voltage across all the LEDs, subtract it from the power supply voltage, and divide the resulting remainder by the given current.

R = (U - (U_HL_1 + U_HL_2 + U_HL_3)) / I

Let's assume that the power supply voltage is 12V, and the voltage drop across the LEDs is 2V, 2.5V and 1.8V. Even if the LEDs are taken from the same box, there can still be such a scatter!

According to the condition of the problem, the current is 20mA. It remains to substitute all the values \u200b\u200bin the formula and learn the answer.

R = (12- (2 + 2.5 + 1.8)) / 0.02 = 285Ω

Figure 12. Parallel connection of LEDs

On the left fragment, all three LEDs are connected through one current-limiting resistor. But why is this scheme crossed out, what are its shortcomings?

This is where the scatter of LED parameters comes into play. The largest current will go through the LED, which has a smaller voltage drop, that is, less and internal resistance. Therefore, with this inclusion, it will not be possible to achieve a uniform glow of the LEDs. Therefore, the correct circuit should be recognized as the circuit shown in Figure 12 on the right.

In the manufacture of various electronic structures, an LED is often used, for example, in units for indicating or signaling the operation of equipment. Everyone probably worked with conventional indicator LEDs, but not everyone uses a two-color LED with two leads, because few beginner electronics engineers know about it. Therefore, I will talk a little about it and, of course, we will connect a two-color LED to a 220 V AC network, since this topic, for reasons unknown to me, is of increased interest.

And so, we know that a "normal" LED passes current in only one direction: when a plus is applied to the anode, and a minus of the power source is applied to the cathode. If you reverse the polarity of the voltage source, no current will flow.

A bi-color LED with two leads consists of two back-to-back diodes connected in parallel, placed in a common housing. Moreover, the housing or, more precisely, the lens has standard dimensions and also only two outputs.

The peculiarity is that each lead of the LED serves as the anode of one LED and the cathode of the second.

If a plus is applied to one output, and the second is minus the power source, then one LED will be locked, and the second will light up, for example, green.

When the polarity of the power supply is reversed, the green LED will turn off, and the red one will light up.

Bicolor LEDs are available in the following color combinations:

- Red Green;

- blue yellow;

- green - amber;

- Red Yellow.

How to connect a two-color LED with two leads to a 220 V network

It is convenient to use such an LED on alternating current, since there is no need to use a reverse diode. Therefore, to connect a two-color LED to 220 V AC, it is enough to add only a current-limiting resistor.

It should be immediately corrected here that the nominal voltage in the network, it is also in the outlet, starting from October 2015, is no longer familiar to us 220 V, but 230 V. These and other data are reflected in GOST 29433-2014. The same standard provides permissible deviations from the nominal voltage value of 230 V:

- nominal value 230 V;

— maximum 253 V (+10%);

- minimum 207 V (-10%);

- minimum under load 198 V (-14%).

Based on these assumptions, it is necessary to calculate the resistance of the current-limiting resistor from such considerations that it does not overheat and sufficient current flows through the LED for its normal glow with the maximum allowable voltage fluctuations in the network.

Current Limiting Resistor Calculation

Therefore, although the nominal current value is 20 mA, we will take 7 mA \u003d 0.007 A for the calculated current value of the two-color LED. At this value, it normally shines, since the brightness of the LED is not directly proportional to the current flowing through it.

Let's determine the resistance of the current-limiting resistor at a nominal voltage in a 230 V socket:

R \u003d U / I \u003d 230 V / 0.007 A \u003d 32857 Ohms.

From the standard series of resistor values, we select 33 kOhm.

Now we calculate the power dissipation of the resistor:

P \u003d I 2 R \u003d 0.007 2 ∙ 33000 \u003d 1.62 W.

We accept a 2-watt resistor.

Let's recalculate for the case of the maximum allowable voltage at a given resistor resistance value:

I \u003d U / R \u003d 253 / 33000 \u003d 0.0077 A \u003d 7.7 mA.

P \u003d I 2 R \u003d 0.0077 2 ∙ 33000 \u003d 1.96 W.

As you can see, with an increase in voltage by an allowable 10%, the current will also increase by 10%, however, the power dissipation of the resistor will not exceed 2 W, so it will not overheat.

When the voltage drops by an acceptable value, the current will also decrease. In this case, the power dissipation of the resistor will also decrease.

Hence the conclusion: as an indicator of the presence of a mains voltage of 230 V, it is enough to use a two-color LED with two leads and a current-limiting resistor with a resistance of 33 kOhm with a dissipation power of 2 W.

Multi-color LEDs followed two-color "red-green" LEDs when advances in technology made it possible to place blue-colored emitters on their crystals. The invention of "blue" and "white" LEDs completely closed the RGB circle: now it has become a real indication of any color of the rainbow in the visible wavelength range of 450 ... 680 nm with any saturation.

There are several ways to obtain white "LED" light (namely, "light", since white "color" does not exist in nature).

The first way - a yellow phosphor is applied to the inner surface of the lens of the "blue" LED. "Blue" plus "yellow" add up to a tone close to white. This is how the world's first "white" LEDs were created.

The second way - on the surface of a light emitter operating in the ultraviolet range of 300 ... 400 nm (invisible radiation), three layers of a phosphor are applied, respectively, blue, green and red. There is a mixing of the spectral components, as in a fluorescent lamp.

The third way is the technology of television LCD screens. On one substrate, “red”, “blue” and “green” emitters are placed close to each other (like three guns in a kinescope). Color proportions are set by different currents through each emitter. The final mixing of colors until a white tint is obtained is done by a light-diffusing lens of the body.

The fourth method is implemented in the so-called "quantum" LEDs, in which red, green and blue "quantum" dots or, in other words, luminescent nanocrystals, are applied to a common semiconductor wafer. This is a promising energy-saving direction, but still exotic.

Today for amateur practice are of interest multicolor LEDs the third type, having taps from three emitters. They can be used to create full-color information display devices, for example, in the form of TV format LED screens. One pixel of such a screen can shine in blue (470 nm), green (526 nm) or red (630 nm) color. In sum, this allows you to get almost the same number of shades as in computer monitors.

Multi-color LEDs are four-, eight-pin pole. In the first case, there are three outputs for emitters of red (R), green (G) and blue (B) colors, supplemented by a fourth output of a common cathode or anode. In the six-pin version, three completely independent RGB LEDs or two two-color pairs: “red-blue”, “green-blue” are placed in one housing. Eight-pin LEDs additionally have a "white" emitter.

An interesting point. It has been proven that most men inaccurately perceive color in the red part of the spectrum. Mother nature herself is to blame for this because of the OPNlLW gene located on the X chromosome. In men, this gene is one, and in women there are two copies of it, which mutually compensate for each other's defects. Manifestation in everyday life - women, as a rule, distinguish crimson, burgundy and scarlet shades well, and for many men such tones seem equally red ... Therefore, when designing equipment, one should avoid “conflicting” colors and not force the user to look for differences in small details.

On Fig. 2.17, a ... and diagrams for connecting four-, six-pin multi-color LEDs to MK are shown.

Rice. 2.17. Connection schemes for multi-color LEDs to MK (beginning):

R3* so o a) the current through each of the three emitters of red (R), green (G) and blue (B) colors is determined by resistors R2 ... R4 - no more than 20 ... 25 mA per MK line. Resistor R1 organizes negative feedback by current. With its help, the overall brightness of the glow is reduced while simultaneously turning on three emitters at once;

b) similar to Fig. 2.17, a, but for the HL1 LED with a common anode and with an active LOW level at the MK outputs;

c) Three-channel PWM control provides full RGB color gamut. The resistances of resistors R1 ... R3 are selected over a wide range according to the subjective color sensation of white balance with three emitters turned on. For a uniform transition from one color to another, a nonlinear PWM control law is needed. The average current through one MK line for one PWM period should not exceed 20 ... 25 mA with a pulse current of not more than 40 mA;

d) similar to Fig. 2.17, c, but for the HL1 LED with a common anode and with an active LOW level of PWM signals;

e) the HL1 LED contains three completely autonomous emitters with separate leads from the housing, which gives a certain freedom of action. For example, you can make the connection of indicators according to the scheme with both a common anode and a common cathode; O

About Fig. 2.17. Schemes for connecting multi-color LEDs to MK (end):

f) multicolor LED simulator. Three conventional LEDs HL1..HL3 of red, green and blue colors are structurally placed in one common light-diffusing housing. For a better imitation of the original, small-sized SMD LEDs can be used;

g) powerful multi-color LEDs cannot be connected directly to the MC, due to the low load capacity of the ports. Transistor switches are required with a permissible current of at least 500 mA for "one-watt" LEDs (350 mA) and at least 1 A for "three-watt" LEDs (700 mA). It is recommended to power the MK and the HL1 LED from different sources through a voltage regulator so that interference from switching a powerful load does not interfere with the program. With a high supply voltage of the HL1 LED, the resistance of the resistors R4 ... R6 and their power should be increased. The LED itself must be installed on a radiator 5 ... 10 cm 2;

h) six-pin LED HL1 is controlled by four lines MK. By combining LOW/HIGH levels, different color tones can be achieved. Ideally, a mixture of blue and green produces cyan, and a mixture of red and green produces yellow;

i) the 8-pin LED HL1 allows not only mixing the colors red (R), green (G), blue (B), but also adjusting their saturation by adding a white component (W). Each of the emitters of the HL1 LED is designed for an operating current of 350 mA, so it is necessary to provide measures for efficient heat dissipation by a metal radiator.

Multi-color LEDs, or as they are also called RGB, are used to indicate and create a backlight that dynamically changes in color. In fact, there is nothing special about them, let's see how they work and what RGB LEDs are.

Internal organization

In fact, an RGB LED is three single-color crystals combined in one package. The name RGB stands for Red - red, Green - green, Blue - blue, according to the colors that each of the crystals emits.

These three colors are basic, and any color is formed by mixing them; this technology has long been used in television and photography. In the picture above, you can see the glow of each crystal separately.

In this picture you see the principle of mixing colors to get all shades.

Crystals in RGB LEDs can be connected as follows:

With common anode;

With a common cathode;

Not connected.

In the first two options, you will see that the LED has 4 pins:

Or 6 conclusions in the latter case:

You can see three crystals clearly visible under the lens in the photo.

For such LEDs, special mounting pads are sold, they even indicate the purpose of the conclusions.

One cannot ignore RGBW - LEDs, their difference lies in the fact that in their case there is another crystal that emits white light.

Naturally, it was not without tapes with such LEDs.

This picture shows a strip with RGB LEDs, assembled according to a common anode scheme, the glow intensity is adjusted by controlling the "-" (minus) of the power source.

To change the color of the RGB tape, special RGB controllers are used - devices for switching the voltage supplied to the tape.

Here is the RGB SMD5050 pinout:

And there are no ribbons, there are no special features for working with RGB ribbons, everything remains the same as with monochrome models.

For them, there are also connectors for connecting the LED strip without soldering.

Here is the pinout for a 5mm RGB LED:

How the color of the glow changes

Color adjustment is carried out by adjusting the brightness of the radiation of each of the crystals. We have already considered.

The RGB controller for the tape works on the same principle, it has a microprocessor that controls the negative output of the power supply - connects and disconnects it from the circuit of the corresponding color. The controller usually comes with a remote control. Controllers come in different capacities, their size depends on this, starting from such a miniature one.

Yes, such a powerful device in a case the size of a power supply.

They are connected to the tape according to the following scheme:

Since the section of the tracks on the tape does not allow connecting the next section of the tape in series with it, if the length of the first exceeds 5 m, you need to connect the second section with wires directly from the RGB controller.

But you can get out of the situation, and not pull an additional 4 wires 5 meters from the controller and use an RGB amplifier. For its operation, you need to stretch only 2 wires (plus and minus 12V) or power another power supply from the nearest 220V source, as well as 4 "information" wires from the previous segment (R, G and B) they are needed to receive commands from the controller, so that the whole structure glows the same way.

And the next segment is already connected to the amplifier, i.e. it uses the signal from the previous piece of tape. That is, you can power the tape from an amplifier that will be located directly next to it, thereby saving money and time on laying wires from the primary RGB controller.

We adjust RGB-led with our own hands

So, there are two options for controlling RGB LEDs:

Here is a variant of the circuit without the use of arduin and other microcontrollers, using three CAT4101 drivers capable of delivering current up to 1A.

However, now controllers are quite cheap, and if you need to adjust the LED strip, then it is better to purchase a ready-made version. Circuits with arduino are much simpler, especially since you can write a sketch with which you will either manually set the color, or the selection of colors will be automatic in accordance with the specified algorithm.

Conclusion

RGB-LEDs allow you to make interesting lighting effects are used in interior design, as a backlight for household appliances, for the effect of expanding the TV screen. There are no special differences when working with them from ordinary LEDs.

Popular

- Program for changing the angle of attack and pitch

- Actual output speed Calculation of closed gear train

- What is the procedure for the use of official transport by an employee

- aircraft fuel system

- Agreement for the evacuation of a vehicle Standard agreement for the evacuation of a vehicle

- Bulldozer performance and how to improve it Basic information about bulldozers

- Toyota Production System (TPS) and Lean Manufacturing

- Examination tickets by profession line pipe fitter

- What to do if you don't feel like doing anything

- Globus - shops for the whole family