Barrel manufacturing technology. Manufacture and sale of wooden barrels as a business

Wooden barrels are a rather specific commodity. But there is a certain rather high and, most importantly, stable demand for it. There is very little competition in this segment. Therefore, the production of cooperage products can be a great idea for your own promising business, which does not require large investments.

Of course, 100-200 years ago, wooden barrels were used more widely than they are now. Nowadays, they are used mainly for storing wines and other alcoholic beverages (for example, whiskey or cognac) and for various pickles (for example, for sauerkraut, pickling tomatoes and cucumbers, soaking meat before drying, etc.). One of the latest trends is the use of classic wooden barrels for interior decor. Previously, such barrels were used for bathing. Now they are ordered as a bath or shower with some modifications for country houses, baths, hunting lodges, etc.

The range of such specific products, oddly enough, is very wide, but the most widespread are oak barrels used in wine cellars, and barrels of various capacities for salting products. To open your own production of cooperage products, it is enough to have a suitable area for a workshop, as well as the necessary raw materials. Neither one nor the other difficulties, most likely, will not arise.

The main thing is that you know all the intricacies of the production process and have quite a lot of experience in the manufacture of wooden barrels yourself. The craft of cooperage is taught, as a rule, by masters who, for a fee, agree to take on apprentices. There are also a few enterprises where such products are manufactured and where new workers are trained. Experts believe that it is possible to take on the production of barrels for sale only after several dozen self-assembled products under the supervision of an experienced craftsman. Having gained some experience and knowledge, you can open your own workshop. Of the necessary materials, you will need wood, metal hoops, special machines. Most likely, finding experienced coopers to work in your workshop will not be easy, and you will have to hire newcomers and teach them the tricks of this craft yourself.

Oak barrels are made from boards that are purchased from logging companies. The barrel production process itself begins with planing the boards, giving them the necessary shape and form, as a result of which the so-called staves are obtained. Staves are called small rectangular planks with a pronounced texture.

They are harvested from a certain type of wood (which one depends on the purpose of the future product). It is from staves in the literal sense of the word that a wooden barrel, tub or any other wooden product of this type is assembled. These wooden planks are tightly joined to each other with metal hoops. For the highest quality barrels, which have the longest service life, the staves are carefully dried under a canopy in an open area for several months. The entire process of making cooperage products is carried out, as it was several centuries ago, entirely by hand.

Dried staves are sent to a special steam room, where they are heated and moistened with steam, as a result of which the wood becomes more flexible and can be given various shapes without the risk of breaking. As mentioned above, a wooden barrel is created by fastening the staves with hoops, and at first the hoops are attached only on one side, slightly tightening the product. Such a blank, fastened on one side, is called a "rose". The planks are carefully joined together, the product is given the desired shape (there are several dozen different types of shapes in total). The bottom is inserted and, if necessary, a cover.

After finishing the preparatory work, oak barrels are fired on an open fire for 30-50 minutes. To do this, special fires are lit in the cooperage, on which the body of the barrel without a top and bottom is put on top. This stage is of great importance for the quality of the finished product. Experts know that the degree of roasting of a barrel for, for example, cognac or wine greatly affects the taste of the drink.

A good wooden barrel should be perfectly sealed. To give the seams of an oak barrel tightness at the junction with the bottom, as well as several centuries ago, modern masters use ... ordinary dough. Flour and water are diluted in a certain proportion, which ensures complete tightness of finished products.

Dry reed leaves are used to seal holes in the bottom. After processing the seams, oak barrels go through the final stage of production. On a special machine, the inner surface of the barrel is turned. The cooper removes the temporary hoops, fixes the permanent hoops and installs the lids.

The finished wooden barrel is ground, polished and processed with special compounds, and then it undergoes a mandatory leak test procedure. To do this, liquid is poured into the barrel. Then the product is tested on a special apparatus that shakes it with all its might. If after the test the wooden barrel did not leak, then it is ready for sale.

Some manufacturers offer additional services for branding their products using a special laser that inscribes and images (for example, logos) on wood.

A do-it-yourself wooden barrel made will allow not only to save money, but also to get a high-quality elegant product. Barrels made of wood were used by our ancestors for pickles, making alcoholic beverages and storing water, which proved their versatility. Therefore, they are still successfully used today. How to make a wooden barrel so that it is durable and does not leak? What tools and skills are required to make a barrel at home?

If you are determined to achieve your goal and are not afraid that you will have to refine the product to the desired state, then you can make your dream come true and make a wooden barrel yourself. Cooper is a difficult profession that came to us from past centuries. Today, there are few masters of this craft, and there are even fewer high-class specialists in the manufacture of barrels, so free-selling barrels are a rarity, and not everyone can afford the cost of the product.

Tools

To make your first barrel or small barrel, you need to prepare a place in which it will be convenient to work, tools and suitable material. In addition to the carpentry kit necessary for making a barrel with your own hands, you need to purchase cooperage devices:

- carpenter's workbench, fitted for the manufacture of barrels;

- long jointer and circular humpback planer;

- a device for planing edges on the boards, a barrel will be assembled from them;

- equipment for tightening rivets (pillar gate, chain coupler and frame gate machine);

- skobelya, plow, bracket;

- templates and patterns of own production;

- clamps made of wood, metal (for assembling the skeleton of the barrel);

- morning time - a device that allows you to cut the morning groove, where the bottom part is inserted.

You need to understand that it is quite difficult to purchase these tools, wood and fixtures on the market, since almost all coopers make machines and layouts on their own, taking into account their height. This is done by trial, no instruction will help.

What you need to know

The main difference between cooperage products is the assembly from pre-prepared wooden boards (staves). The size and shape of the barrel is completely dependent on pre-prepared boards, the configuration of which is set by the cooper. And the initial quality of wooden barrels depends entirely on the chosen wood. For this reason, it is not enough for the master to have a thorough knowledge of the instrument. You need to know the subtleties of each type of wood from which wooden products will be made.

An experienced master will not make a barrel for honey from oak blanks, because he knows that in such a container, honey will quickly acquire a completely different flavor and darken. But it is impossible to find a replacement for oak barrels for aging wines and cognac.

The second element is a hoop that pulls together all the components of the barrel. It is thanks to the hoop that water does not seep through the joints between the boards. It can be made from metal or wood. As the experience of the craftsmen shows, metal hoops are much stronger, and less time is spent on manufacturing than wooden hoops. But some masters still prefer a wooden hoop, giving the barrel a more beautiful look.

Details and the principle of manufacturing products

Many people think that becoming an amateur cooper is very difficult, and dreams never come true. But if you are not used to backing down from your decisions, then you need to decide which option will be your first job.

In total there are 3 types of products: conical, cylindrical and parabolic. Each corresponds to a certain type of rivets:

- Products made in the form of a quadrangle, the long sides of which look like a parabola, are used for dishes with convex edges: barrels or barrels.

- The circuit in the form of a cylinder is simple. It is easy to make and connect it with hoops of the same diameter, but when the wood dries out in this design, the riveting ceases to perform its functions. This is the main reason why such containers are practically not manufactured.

- The shape of an elongated trapezoid makes it possible to obtain durable dishes when stuffing staves. Therefore, this type of product is often suitable for the manufacture of tubs, tubs and other utensils.

As an experimental sample, it is better to stay on a simple small barrel.

Many are interested in how an ordinary tub is made. The barrel is the simplest cooperage product, having achieved a result in its manufacture, you can switch to more complex types of dishes, for example, make a wooden barrel with your own hands.

The principle of creating a product consists of the following steps:

- production of blanks;

- assembly of dishes;

- Finishing work.

The reliability of the structure will depend on the quality of the riveting blank, therefore the most suitable are blanks from logs of sawn wood, gouged out with an ax. For barrels, the most common wood option is oak, as it splits easily in the radial direction. The process of harvesting staves from different tree species is practically the same; a single-row or double-row punching method is used. For large decks, a two-row method is used, and for thin chocks, only a single-row method is used.

The procedure for punching out rivets is as follows:

- The ridge must be carefully split in half so that the split line runs strictly along the center of the workpiece.

- Each chopping block must be split in two to get 4 equal parts.

- Next, you need to split the wood for harvesting in half again to get 8 equal parts. Usually for small logs this is quite enough. It is 1/8 of the part that will become the riveting blank.

- If the ridge is thick, a two-row knockout is used, i.e. each of the 8 parts splits into 2 equal parts along the growth rings.

- The resulting logs must be split in the radial direction. The result will be 1-2 smaller blanks and 2-5 for larger blanks.

- Next, you need to cut off the wedge-shaped protrusions and young wood from the side of the bark. Only after that it is possible to dry the workpiece in an open area or resort to artificial drying.

Making staves

In order to make rivets from the prepared material, you must first prepare the drawings and a template for a specific product in accordance with the desired shape. To get ready-made rivets, you will need:

- Run markup.

- Make a rough processing of each of the blanks. Namely, round the outer surface, bevel the edges with an ax.

- Perform finishing with a planer, constantly monitoring the result with a template.

- Plane the inside of the workpiece with a humpback staple.

- Trim narrow edges, then level their surface with a jointer.

In the process of making barrels, the cooper has to make tightening hoops on his own. The easiest way to get a hoop is from steel tape. To do this, you need to determine the diameter of the container and add double the strip width to the resulting figure. Next, using a hammer, you need to bend the tape into a ring, drill 2 holes and fix them with rivets. To make a small barrel, you will need 2 hoops that will correspond to the diameter of the upper and lower parts of the product.

Bottom assembly and installation

- Plane the edges of the boards, fix on a workbench and divide the radius into 6 parts.

- Within the circle, mark the places for installing the studs.

- Pull out the boards. Drill holes in the edges, drive wooden or metal studs into them.

- Dock all the elements tightly and secure with studs, after which you can cut the bottom.

- Cut out the bottom, leaving a small margin.

- Chamfer with a straight plow and knock down the hoop, loosening the fastening of the rivets.

- Insert the bottom into the chime and turn the tub upside down.

- Drop the hoop.

It remains to make a lid on the tub and, after checking the design for strength, proceed to use the container. If the work done was to your liking, it makes sense to continue working on the manufacture of barrels.

If you are engaged in the manufacture of your own wine, pickles, then you know that there is no better container than a wooden barrel. After all, made of wood, it becomes one of the main points in the recipe, it is an environmentally friendly raw material that preserves the taste and useful properties of products. In addition, the alcohol contained in wines or moonshine, when interacting with containers made of synthetic materials: plastic, nylon, can dissolve them and the interaction products are mixed with the drink.

Purchasing a barrel for your winemaking or brining is not difficult, but if you want to save money or like to do everything yourself, then it is worth learning the technique of making an oak barrel with your own hands. This is a process that takes a lot of time and effort, but with our advice, you will see that making a barrel with your own hands is not so difficult even for those who have never done it.

The manufacture of barrels from wood is called "cooperage", and the master who deals with this business is a cooper. This is a whole art that originated in ancient Greece and is still popular. The technology has not changed for thousands of years, is time-tested and not as difficult to implement as it seems at first glance. But how to make a barrel yourself in modern conditions?

Choosing wood

First of all, of course, choose the material from which you are going to make your future barrel. We will offer you the main types of wood that coopers prefer, tell you what their positive and negative sides are, and also help you choose the most suitable option for you.

Oak

Of course, first of all, we should talk about the manufacture of oak barrels. This wood rightfully deserves the title of a classic material used by master coopers. With high strength, flexibility, this tree contains "tannins" that act as an antiseptic. The moisture acting on the walls of such a barrel makes them stronger. Therefore, the service life of oak barrels is measured not even in tens, but in hundreds of years. With drinks stored in such a barrel, the processes of oxidation and interaction with wood take place, and they acquire a pleasant aroma with a hint of vanilla.

Fur tree, pine tree

These types of wood are also used as material for the manufacture of barrels. They are soft, easier to process and cut, but inferior in strength to oak and many other species. Their disadvantage is the smell of resin, which is why this type of wood is rarely used as a material for barrels.

Cedar

Of the representatives of coniferous varieties, coopers prefer it, especially in those places where its natural habitat is located. By properties, it is similar to pine or spruce, but such barrels have no smell. They are well suited for storing products, especially for dairy products.

Linden

This type of wood is fibrous, perfectly cut and processed. Strong material, does not give in to drying out, does not smell. Linden barrels are recognized as the best for storing and transporting honey, caviar, and pickles.

Aspen

This is a cheap, but long-lasting material, it is strong, resistant to moisture, and has antiseptic properties. Aspen was recognized as ideal for pickling and storing vegetables. The peculiarity of this variety is that it swells a lot, but for a cooper it is rather a plus, because thanks to this, the rivets close tightly.

We make rivets

So, you have decided on the type of wood, let's say it will be oak. Now we make the details of the barrel, starting with the rivets. These are tapering at the edges, or rectangular boards (sawn or chipped). The latter win in terms of strength due to the structure of the fibers, which does not undergo destruction during splitting.

The shape of the stave depending on the type of barrel

To determine the exact number of such rivets, do the following:

- Determine the required barrel parameters

- Make drawings of your design

- Create sketches of riveting and bottoms in natural sizes

After these procedures, perform simple calculations that allow you not to miscalculate how many rivets you need. It is calculated by the formula: 2*Pi*R/Sh, where:

- Pi is a constant value of 3.14

- P - radius of the bottom (if the sides are equal) or the middle (if the sides are convex)

- W - size of the width of the riveting

Barrel sizes depending on volume

It will take a lot of time and labor to make stab rivets; certain skills are needed here. The main thing to do is to split the workpiece so that fragments with a smooth surface are obtained.

Scheme of the split of the fire on rivets

There are two main ways to split:

- Radially (the split goes through the core of the deck, which requires less effort)

- Tangentially (does not affect the core, not recommended for use on hardwood, it makes the process slower and more difficult)

It is easiest to process raw material, freshly cut is best. If you use ready-made boards, make sure that the annual rings go along their plane, without sawing.

After harvesting, you need to dry it, in the summer, in the air, under a canopy, this period will be from 3 months. For artificial drying, the following method is used:

- Glue paper on the ends of the rivets

- Place in oven

- Leave it there for a day

Ready for barrel staves

The blanks are now ready for further work.

We make a hoop

Another detail is the hoop. It helps to connect all the rivets, creating a single whole; stainless steel is used to make the hoop.

Modern barrels have three hoops:

- Farts (closer to the center)

- Morning (closer to the edge)

- Neck (if the barrel has a large volume, they are additionally placed between the first two)

The size of the hoop depends on the volume of the container (thickness*width):

- Up to 25 l - 1.6mm * 3cm

- 25 - 50 l - 1.6mm * 3.6cm

- Up to 100 l - 1.6mm * 4-4.5cm

- 120 liters and more - 1.8 * 5cm

Stainless steel barrel hoops

You will need temporary metal hoops, which are made according to the following algorithm:

- Cut the desired size strips from a sheet of steel

- Make holes at the ends of the strips, which are fastened with rivets

Collecting the barrel

Now we have approached the main stage - the assembly of a barrel, consisting of staves, which are connected first by temporary, and then by permanent hoops.

Process with a tool - grinding, cut off uneven ends, drill a filler hole.

Watch a video on how an oak barrel is made.

Oak barrel repair

Do you have an old barrel that you do not use because it is dry, leaking, or for some other reason it is not suitable, watch the video on how the repair is done.

The second part of the video if the barrel is flowing

One of the most interesting ideas that can be put in the basis of a successfully developing business is the production of barrels. They have found their application since ancient times, when they played the role of a vessel for storing wine and water. In addition, they were also used as bathtubs.

Currently, wooden barrels are not as popular in use as they used to be. The explanation for this is quite simple - the fact is that the production process of these products has become much simpler after the advent of cheap modern technologies and materials.

As a result, barrels are now made even from metal and various types of plastics. Be that as it may, the production of barrels has not completely disappeared. Moreover, modern masters are able to create exact copies of copies that were produced by our ancestors. As practice shows, you can also make good money on this.

Barrels for liquor

One of the most common applications of wooden barrels in our time is the storage of alcoholic beverages. Most often they are wine, cognac and whiskey. In this case, oak is considered the most successful material for them, since this tree allows you to preserve the aroma and taste of the drink. It is in such containers that elite and expensive wines are stored. In this regard, the production of oak barrels as a type of entrepreneurial activity looks very promising.

Barrels for pickles

Salting is the second most popular area of application for these vessels. They perfectly preserve sauerkraut, pickled tomatoes and cucumbers. Moreover, in such containers it is very convenient to soak the meat before smoking or curing it.

In this case, you can use both small kegs and more impressive vessels in which a large number of products are placed. In any case, their unforgettable taste is achieved precisely through the use of wooden barrels, and not glass jars.

Barrels in design

The production of barrels for interior decoration is a relatively new idea. Many modern designers who think creatively install such containers even instead of the well-known familiar bath.

Such an idea seems to take a person into the past, because it was the barrels that many years ago were used in the form of a bathing container. Especially such containers are in demand in cottages located outside the city. Be that as it may, an oak barrel placed on a personal plot, in a living room, kitchen or other room, looks unusual and original.

Basic knowledge in cooperage

In order for the process to really bring good profit, first of all, this activity must be liked. And it needs to be understood. For which, in turn, it is recommended to acquire certain skills in cooperage. Do not be sorry for this time, because the lack of understanding of the subtleties involved in the manufacture of oak barrels will not lead to the desired result.

You can get them by learning from a professional cooper or by getting a job for a while at an enterprise that specializes in this field of activity. As practice shows, in order to thoroughly study this process, it is necessary to independently assemble at least a few dozen wooden barrels.

Workshop opening

In order to be engaged in the manufacture of wooden barrels as a business, you first need to register your company. In this case, you can get the status of a legal entity or a private entrepreneur. In addition, it is necessary to become registered with the tax authorities.

To open your own enterprise, which specializes in the production of barrels, you need a room, the size of which depends on the planned production volumes, a warehouse for storing finished products, as well as material. The role of the latter is wood and metal hoops, which are necessary for fastening the barrels. Among other things, you will need staff.

When organizing this type of entrepreneurial activity, the most difficult thing is to find qualified specialists who will fulfill orders at the enterprise. As practice shows, in some cities there are often cases when it is either impossible to find them at all, or craftsmen from neighboring settlements simply do not agree to move. There is only one way out of this situation - to train your employees yourself.

Where does production start?

The manufacturing technology of oak barrels is quite simple. At the initial stage, a riveting is made, which is a small plank that has a rectangular shape and a particularly pronounced texture. Oak is most often used as a raw material for them.

Along with this, it should be noted that, depending on the scope, other types of wood are often used. Based on the technology, each of the staves must be dried under an open canopy for at least two years. Thanks to this, the barrel will be durable and of high quality.

Barrel assembly

At the second stage, the container is directly assembled. Some special equipment for the production of wooden barrels is not used - just like two hundred years ago, they are assembled by hand. Based on the technology, it is first necessary to send the riveting for a while to a steam room specially designed for this. After the wood is moistened and warmed up in it, it will become more flexible. Due to this, the risk of its breakage during assembly is leveled.

The final stage of production

The last stage in the manufacture of wooden barrels is the assembly of the skeleton. In this case, the boards are joined, as a result of which the product receives its shape (dozens of its variants are read). After the lid and bottom are exposed, the structure is fixed by using metal or wooden hoops. Next, the barrel is fired for about 30 minutes on fire, after which it is polished and opened with specially designed compositions.

conclusions

In words, the production process of wooden barrels looks a little easier than it actually is. It is not so difficult to learn this craft - for this you need only desire. Such products are currently in high demand on the market. At the same time, it is not so easy to find a professional master. In this regard, you should not delay opening a business, because, having taken a free niche in the market so far, you can make good money.

For a time when mankind did not have access to simple and reliable plastic packaging. Formed, a whole layer of culture associated with the manufacture of wooden mugs, barrels and other utensils.

There is a great variety of types of wooden barrels. Each wooden barrel serves its own purpose, so the craftsmen selected the most convenient sizes and shapes of products. The most successful, the work of artisans, took root among the people, and began an almost unchanging procession from century to century, from generation to generation.

The main types of barrels

The main types of wooden barrels are shown in the figures below.

Gang, was used for rinsing in baths and small household needs, in the midst of fun they drank mead from them.

Zaparnik, a very convenient invention. Used, of course, in the Russian bath. Boiling water was poured into it and brooms were placed, all this was covered with a lid on top and handles from brooms were in the slots.

conical barrel, used to store various supplies in the cellars, in the winter season.

classic barrel, has found its application all over the world, its design is extremely durable and successful. this barrel is suitable for any products of pickled wine, in general an extremely useful invention.

Fonts, were a favorite place for baptism in churches, and were also used for rinsing in cold water after a bath. The remains of huge fonts are found at the excavations. For example, in Greece, a font was discovered that could accommodate seven people.

Barrels for salting, and fermentation differed in a cone shape and a lid with grooves. A large stone was laid on the lid as oppression. And when the weight of the stone was not enough, wedges were driven into the slot, which created even more tension.

Perhaps the last of the barrels is used to this day - this .

Most of all, do-it-yourself spherical barrels were used before, as they resist well the action of external forces, shocks and blows; the hoops of these barrels firmly tighten the frame, successfully resist the pressure exerted by the contents of the barrel, and easily roll over.

Cylindrical barrels are easy to manufacture, but they are inferior in quality to convex barrels, since with a slight shrinkage the hoops cannot be tightened. They are used to store dry or thick and viscous products; they are no longer suitable for wine.

Tapered barrels are also easy to make with your own hands. The top and bottom bottoms are different sizes. These barrels were mainly used as open-type household utensils.

The barrel consists of a skeleton assembled from the klepchins of the sidebar; bottoms collected from klepchins of sweet clover; hoops (iron or wooden) fastening the skeleton. The design of a spherical barrel is considered strong if the following ratios are observed in the dimensions of height and diameter.

The height is greater than the diameter in the middle by 20-25%; the diameter in the middle is 15% larger than the end diameter.

The most durable is considered a barrel, the skeleton of which was assembled from klepchins of the same width and fastened with iron hoops.

Stages of making wooden barrels

The manufacturing technology of wooden barrels consists of the following operations: riveting processing, assembling the skeleton, manufacturing and inserting bottoms, stuffing permanent hoops.

The riveting harvested in the forest is rather roughly processed planks (klepchins) of a rectangular shape with allowances for thickness and width for processing and shrinkage.

To obtain klepchins, a sidewall of the required length, they are trimmed, and to give the appropriate shape they are cut off, making one side slightly concave, the other slightly convex, then planed clean. The processing of the sidewall riveting ends with jointing of the side edges at a certain angle to the inner surface of the riveting.

The skeleton of the barrel is assembled as follows. Klepchins have one end inside the temporary hoop. The other end of the klepchins is pulled together by means of a gate (Figure 3) and fixed with a second temporary hoop.

After that, the skeleton is closed up: the ends are cut off, chamfered from them, the skeleton is cleaned inside along the line of the chimes, and the chimes are cut.

Klepchins of sweet clover are pre-cut and planed clean, then sewn into square shields using rhombic iron plates as in the figure below (position 1). The shields are planed, then circles are marked on their surface with a compass in accordance with the diameters of the bottoms and the bottom is cut out. A chamfer is removed along the circumference of the bottom, with which it is inserted into the chime of the core (position 3). When inserting the bottom, a temporary hoop is removed from the end of the core, and the second is lifted. At the same time, the screed of the core weakens, the klepchins diverge somewhat, and the bottom chamfers into the chime of the core.

After inserting the bottom, temporary hoops are replaced with permanent ones. Iron hoops (position 2) are stuffed 6-9 each, wooden hoops 14-16 pieces per barrel, placing them in nests of 7-8 pieces. Often they make barrels with different hoops - iron and wooden. In this case, iron hoops are placed in chimes, wooden hoops in the neck and convex part.

Determining the capacity of a barrel

Manufacturing technology of wooden barrels.

The capacity of the barrel is calculated using the following formula:

- V - barrel capacity in m3;

- D - larger diameter in m;

- d is the smaller diameter in m;

- h is the internal height of the barrel in m;

- π - constant number 3.14

You can also determine the capacity of the barrel by filling it with water from a measuring vessel.

Popular

- Creation of the Procter & Gamble brand

- Business essence, functions and classification

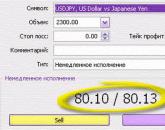

- Price action (Price action) - how to earn?

- Traders millionaires from Russia Top richest traders

- Your own small business idea

- Ideas for small business with minimal investment

- Small Business - Home Production Ideas

- Small Business - Home Production Ideas

- What can be produced at home for sale

- Sheep breeding business plan