Bread baking business. Bread business: how to open a bread kiosk

Bakery and confectionery products are always in demand, these products are regularly bought by all segments of the population. If you draw up a competent business plan and properly organize the business, a bakery, even in a mini-format, can become a highly profitable business.

Mini-bakery at home

A bakery from scratch can be opened in several formats:

- full cycle workshop;

- specially equipped part of the kitchen.

The choice should depend on the expected production technology, scale and desired assortment. A mini-bakery at home can operate in full (includes all stages of bread production) or incomplete cycle (when products are baked from frozen semi-finished products). If the first option is chosen, then a minimum of 80-90 m² of area will be required. Bakeries of this format, as a rule, produce branded confectionery products, form a wide range of bakery products with a capacity of 120-150 kg / hour. The owners get the opportunity to control the production process, independently form the assortment.

If you open a bakery operating in a part-time format, you can easily create a wide range of products, they are characterized by waste-free, clean production. Even 35-40 m² will be enough for work. The capacity of such a small enterprise is enough to produce 0.2-5.0 tons of bread per day. The advantage of such an organization of work is that there is no need to purchase raw materials for making dough. Using the equipment is simple and convenient, additionally no complicated technical devices are required. The influence of the human factor is also significantly reduced, the amount of finished products is much easier to control.

Advice: there is no pronounced difference in taste between baking from semi-finished products and fresh dough, because blanks are prepared, as a rule, from natural ingredients, without flavor enhancers.

Mini-bakeries opened at home from scratch have many advantages:

- do not require huge investments;

- they can be opened even in the home kitchen;

- allow you to work without dependence on intermediaries, which allows you to form favorable prices for customers and achieve high business profitability;

- enter into direct contracts with suppliers of certain raw materials;

- the owner gets more opportunities to attract potential buyers (promotions, organize demonstrations of the baking process for advertising purposes);

- you can freely vary the range depending on the interests of the buyer and resources.

The owners, referring to experience, emphasize that in order to ensure high profitability of the business, it is important to choose the location of the outlet correctly in advance (the traffic must be high). Even if there is no start-up capital, you can organize, for example, dropshipping, writing texts to order, making gifts, decorative soaps, confectionery (cakes, muffins) to order.

How to open a mini-bakery from scratch?

Before opening mini-bakeries from scratch at home, it is important to solve the issue of marketing finished products and the prospects for countering competitors (and there will always be at least 2 of them - mass producers, for example, bakeries and retailers). It is also important to choose the right or LLC. The best option for choosing a taxation system is UTII, the alternative is STS 6% or 15%.

You will also need a quality certificate and a permit for production activities, a conclusion on the compliance of the premises and equipment with fire safety requirements, and permission from the environmental inspection. It will also be necessary to hand over samples of pastries for analysis to the laboratory. It is important to remember that every employee of a mini-bakery is required to have a medical book. will be held no more than once every 3 years. The inspection plan can be found on the website of the Prosecutor General's Office of the Russian Federation or on the website of the Office of Rospotrebnadzor.

An important issue is the formation of the assortment. It should be varied and interest buyers. To maintain their interest, it is necessary to focus not only on quality and price, but also on the formation of new taste qualities, fillings, and forms of baking. The mass product of ordinary stores will never be able to compete on equal terms with the quality branded products of mini-bakery.

Advice: according to bakers, it is possible to create new tastes using natural baking mixes. For example, a culinary additive made from rye flour, heat-treated malt gives baked goods a dark color, a special taste and aroma. Also, the mixtures extend the shelf life, improve the quality of products and allow you to optimize the production technology (dry sourdough helps bread rise not in 3, but in 1 hour). In addition, their consumption is very small.

How to open a personal mini-bakery? The algorithm of actions looks like this: registration of a mini-bakery, search and preparation of premises, selection and purchase of equipment, search for personnel, registration of permits, purchase of raw materials, start of work. For this, you will also need permits and careful preparation of all stages. One of the most important aspects is the choice of a place with good traffic, a comfortable position of the room.

What advantages should mini-bakery owners have in the competition:

- Quality and freshness of products.

- Range.

- More favorable price.

- Quality of service.

- Design decoration of the point of sale (this can be done with your own hands without large financial costs).

To open a profitable business, you should pay special attention to some typical mistakes:

- lack of a clear strategy for the development of the case, inconsistency in actions;

- insufficient funding;

- the sales market is not prepared at the initial stage;

- lack of competitive offers for the buyer.

What equipment do you need for a bakery?

You can open a successful full-cycle bakery only if you have high-quality equipment: pastry tables, trolleys, flour sifter, dough mixer, dough divider, croissant and baguette molding machine, proofer and oven (hearth, rotary), trays, stainless steel trays steel, culinary tools (knives, brushes, scrapers, special utensils). Also, various units will be additionally needed, for example, a lift with a bowl tipper, a seamer.

For part-time bakeries, less equipment will suffice. The main thing is to have a proofing cabinet for defrosting semi-finished products, an oven, a refrigerator for storing blanks.

Equipment for a mini-bakery - ready-made kits

Before you open a bakery, it is important to choose quality mini-bakery equipment from scratch. It is not necessary to buy it individually, there are ready-made kits for sale. The average price is 2800000-5666768 rubles. Turnkey mini-bakeries are produced on the basis of a gas, electric or diesel oven. They include the following equipment:

- oven (rotary gas, electric or diesel);

- proofing cabinet;

- shelving trolley;

- sifter of loose products;

- dough mixing machine;

- rolling bowl;

- additional (hearth sheet, cassette of bread forms) and auxiliary - a production table with a table top, desktop, floor scales, a tray trolley, a bread tray.

An indicative table of utility costs for bakeries operating on the basis of ready-made sets of equipment:

Costs directly depend on the configuration of the equipment and its capacity.

How much does it cost to open a bakery?

On average, to open a full cycle mini-bakery from scratch, you will need 1,500,000 rubles. with a production volume of 45,000 kg per month. To increase sales, assistants may be needed (key workers 4, specialists 2, clerks 2, support workers 4), making the costs high. It is also important to navigate the prices of equipment, the average price:

- oven (900 thousand rubles);

- dough mixing machine (380 thousand rubles);

- proofing cabinet (60 thousand rubles);

- dough sheeter (30 thousand rubles);

- cart for baking (15-19 thousand rubles);

- table for cutting dough (60 thousand rubles);

- flour sifter (14-15 thousand rubles).

Electricity costs average 75 thousand rubles. (18,000 kW) per month. Also, monthly expenses include the rental of premises - in the region of 10-15 thousand and the purchase of raw materials (with a volume of 1500 kg of products, about 500 thousand rubles will be needed). It is important to take into account the cost of auxiliary materials (packaging film, labels) - about 40 thousand. The net profit under such a project will be about 125 thousand rubles. And it pays off in an average of 12 months. The higher the throughput of the outlet, the greater the profit.

If you open a bakery in the home kitchen, the costs, of course, will be lower, the purchases of raw materials are made in lower volumes, but the productivity will also be lower, the payback period will increase.

The bakery business is considered one of the most highly profitable. Experts say that with any forecast of the market development, its profitability cannot fall below 25%. The largest segment of this market is occupied by mass products (bread, bagels, crackers, confectionery), non-traditional offers (lavash) are in second place, followed by dietary baked goods and 5% of the market belongs to elite products. It is in the last segment that a mini-bakery can make itself known best by offering a unique product to the buyer, and reasonably form a high margin. On average, investments can be recouped within a period of several months to 1.5-2 years, depending on the scale of production and its resources. Home bakeries with minimal capital investment will take a little longer to pay off.

Bakery as a business - reviews

Denis:

The bakery has been operating for the seventh year. And, despite the difficulties, I am satisfied. During the work, we had to transfer production 3 times and change the location of the outlet. Most positions in the assortment are occupied by baked pastry pies with various fillings, puff pastry products. I easily sell about 2,500 units through dozens of stores.

Igor:

A few years ago, I managed to open a mini-bakery at home, but it didn’t work out. Disappointed and already counting the losses. But on the advice of a friend, he closed for a while, together with specialists he drew up a business plan, corrected the mistakes and restarted production. I have been working for myself for a year now and I consider opening a mini-bakery a profitable business (if you approach it competently and form a sales market in advance).

Natalia:

Its own mini-bakery at home has been operating for the second year, but the sales problem remains relevant. It seems that everything was thought through and calculated, but this moment is still not fully resolved. Probably, it was worth giving it more attention at the start and working according to a business plan, and not blindly. But I'm still satisfied with the earnings, there are many regular customers who even come to the house.

Bread has been around since the Neolithic era, making it one of the oldest foods. The first bread was a kind of baked gruel made from water and cereals. It is believed that thermal cooking may have been the result of accidental cooking or deliberate experimentation.

Today, the baking industry is considered one of the main branches of the food industry. The main direction in the development of bread production can be attributed to the improvement of the structure of the assortment of bakery products in order to achieve full satisfaction of the population's need for additional raw materials. As well as the development of technological progressive processes for the preparation of dough and the use of installations and units, with the help of which it is possible to automate and mechanize dough management in a complex.

The production of bread should be given special attention in the baking industry, namely the quality of products, the rational use of raw materials, the reduction of losses at all stages of the technological process, and the development of bakery products.

Equipment for the production of bread

Main:

- flour sifter(from $400). It is used for loosening, aeration and additional cleaning of flour. The prepared flour is free from unwanted impurities, has a uniform moisture content and density, and is enriched with oxygen to improve the subsequent fermentation of the dough. Flour sifters come with magnetic traps, thanks to which you can catch metal particles.

- Industrial mixer(from $800). Needed for quick kneading of different types of dough. The dough mixer ensures accurate consumption of products and strict adherence to the recipe, helps to minimize the need for manual labor and eliminate human error.

- proofing cabinet(from $900). Helps in preparing the dough for baking, allowing it to rest, rise and bring to the desired condition and for fermentation. The temperature and humidity set in it ensure a neat and even increase in bread collections, avoiding cracks and dry edges.

- convection oven(price from $1500). It bakes bakery products. There are highly specialized or suitable for different types of dough.

Optional:

- Production tables, flat trays, perforated wavy trays, production tables and racks, bread molds, washing baths, hairpin trolley, scales.

How much money is needed? For an opening with a size of 20 m² for a complex of equipment with a capacity of 400 kg of products for a 12-hour shift, you can meet the amount of $5,000. For 1000 kg of production, a room of approximately 45 m² and an investment of $19,000 will be required.

Bread production technology

Raw materials used in the bakery production process

Reception, storage and preparation of raw materials

The main raw materials of bakery production are water, yeast, salt. Additional raw materials include all other products used in baking, namely animal, margarine, malt, molasses, etc. Currently, new types of additional raw materials for production and improvers are widely used in the baking industry (surfactants, enzyme preparations, modified starch, whey, whey concentrates, etc.

Any bakery enterprise must have a raw material warehouse, where a certain stock of basic and additional raw materials for production is stored. The bulk method of delivery and storage of many types of raw materials (flour, sugar, yeast milk, liquid fats, salt, whey, molasses, vegetable oil) has become widespread. With the bulk delivery and storage of raw materials for bread, the number of employees in the warehouse is sharply reduced, the sanitary condition of warehouses is improved, the culture of production is increased, the loss of raw materials is reduced, and a significant economic effect is achieved compared to the container storage of raw materials

Raw materials for the production of bread, which are stored in a warehouse, must undergo certain preparation before kneading semi-finished products, as a result of which their sanitary condition and technological properties are improved. At the same time, the raw materials are cleaned of impurities, fats are melted, yeast, salt and sugar are dissolved in water. The resulting solutions are filtered and pumped into collection containers, from where they enter the dispensers.

Reception and storage of flour in production

Flour delivered to the bakery from a mill or a base is stored in a separate warehouse, which should accommodate its seven-day supply, which will make it possible to prepare it for production in a timely manner.

Flour for production enters the bakery in separate batches (a batch is a certain amount of flour of the same type and variety, produced simultaneously and received according to one invoice and with one quality certificate).

Analyzing the received flour for production, laboratory workers compare the analysis data with the data of the certificate. In case of significant discrepancies, a representative of the organization supplying flour is called, and the analysis is repeated.

Flour is delivered to production by container (in bags) and bulk (in tanks) methods. The net weight (weight of the product without packaging) of varietal flour in a bag is 70 kg, wallpaper - 65 kg (the weight is set when flour is bagged). Each bag of flour has a label indicating the milling plant, type and grade of flour, net weight, production date.

If substandard grain was added during grinding, a corresponding mark is made on the label.

Flour in the bulk method is stored in silos. To store each type of flour, at least two silos are provided, one of which is used to receive flour, the second - to supply it to the production of bread. The total number of silos in the warehouse depends on the productivity of the plant and its need for different types of flour. Loading of bunkers with flour is carried out from above. The flour transporting air is removed through a filter installed above the hoppers, flour dust is retained and poured into the hopper.

Transportation of flour for the production of bread from storage tanks for sifting, weighing and production bins can be carried out mechanically by means of bucket elevators and augers or by pneumatic and aerosol transport. The latter method has significant advantages due to the saturation of the flour with air, which raises the temperature of the flour and promotes its maturation. Each production warehouse must have at least two lines for cleaning, weighing and transporting flour to production bins.

Storage and preparation of additional raw materials for production

Yeast for bread. In the baking industry, pressed yeast is used, as well as dried, liquid yeast, and yeast milk.

Pressed yeast for baking bread is a collection of yeast cells isolated from the culture medium, washed and compressed. A culture medium is a liquid nutrient medium in which microorganisms are grown.

When preparing pressed yeast for mixing semi-finished products, they are diluted with water at a temperature of 29-32 ° C in tanks with mixers in a ratio of 1: (2-4).

Frozen yeast for bread is stored at a temperature of 0-4°C, they should be thawed slowly at a temperature not exceeding 8°C.

Dried yeast is obtained by drying crushed pressed yeast with warm air to a residual moisture content of 8-9%. Dried yeast is packaged and stored in cans, paper bags or boxes lined with parchment at temperatures above 15°C. Guaranteed shelf life of premium yeast is 12, and I grade - 6 months. Yeast of the highest grade for the production of bread is hermetically packed. When packed in non-hermetic containers, their shelf life is halved. During storage, a monthly deterioration of the lifting force by 5% is allowed. Dried yeast before use should be soaked in warm water until a homogeneous mixture is formed. Many bakeries carry out the activation of pressed and dried yeast. The essence of activation is that yeast for the production of bread is diluted in a liquid nutrient medium consisting of flour, water, malt or sugar, and sometimes other additives, and left for 30-90 minutes. During the short activation process, the yeast cells do not proliferate, but become more active. As a result of activation, the lifting power of yeast is improved, which makes it possible to slightly reduce their consumption for dough preparation (by 10-20%) or, without reducing consumption, to reduce the duration of fermentation of semi-finished products. The use of activated yeast improves the quality of the bread. The acidity of products prepared with activated yeast is 1° higher than usual. Yeast activation options are different.

Yeast milk is a liquid suspension of yeast in water, obtained by separating the culture medium after the yeast has been propagated in it.

Yeast milk enters production chilled to a temperature of 3-10°C in tank trucks with thermal insulation, from where it is pumped into steel containers with a water jacket and an electric mixer, which is turned on every 15 minutes for 30 seconds to ensure a uniform concentration of yeast throughout the mass of the product.

The duration of storage of yeast milk for future bread at a temperature of 3-10°C is 2 days, at a temperature of 0-4°C - up to 3 days.

Salt and sugar. Salt is supplied to low-power bakeries in bags and stored in a separate room in bulk or in chests. Salt, due to its hygroscopicity, cannot be stored together with other products for production. Salt is added to the bread dough in the form of a solution with a concentration of 23-26% by weight. A saturated solution is prepared in salt solvents, which is then filtered and fed into production collections.

Most bakeries use the storage of salt in solution in production. Salt delivered to the bakery by a dump truck is poured into a reinforced concrete bin, which, for the convenience of unloading salt, is deepened by 2.8 m from the floor mark. The bunker has a receiving compartment and 2-3 settling compartments. Pipelines with cold and hot water are held in the receiving compartment. The salt solution by gravity through the holes in the partitions fills all the compartments of the sump and is filtered.

To control the concentration of the solution, which should be constant, periodically check its density with a hydrometer.

The higher the concentration of salt in the solution, the higher the value of the density of the solution. Having determined the density, find the concentration.

Typically, a solution of 25% concentration (solution density 1.1879) or 26% concentration (solution density 1.1963) is prepared. If the density of the solution in the last solvent compartment is insufficient, then the solution is pumped into the receiving compartment. Changing the set density of the salt solution violates the dosage of salt.

Sugar for the production of bread, delivered in bags, is stored in a clean, dry room with a relative humidity of 70%. Sugar is hygroscopic, so it hydrates in a damp environment. Bags of sugar are stacked (on racks) in stacks of 8 rows in height.

If granulated sugar is intended for the manufacture of low-moisture pastry, it is used in dry form and is sifted through a sieve with 3 mm cells and passed through magnetic traps. As a rule, sugar is added to bread dough in the form of a solution of 51-62% concentration with a density of 1.23-1.3. The solution is prepared in tanks equipped with a stirrer and a filter. The syrup from the tanks is pumped into collection containers. The temperature of the solution is about 32-35°C. The solubility of sugar is highly dependent on the temperature of the solution. If you prepare a solution for the production of bread of a higher concentration, then when it is cooled in pipelines, crystallization of sucrose may occur.

In recent years, many bakeries store sugar in the form of a sugar-salt solution. The storage plant consists of a sugar bag unloader, two metal containers, water and salt solution dispensers, filters and pumps. Containers for preparing sugar solution are equipped with steam jackets and agitators. The addition of table salt to a solution (2-2.5% by weight of dry sugar) for bread production delays the crystallization of sucrose and allows the preparation of 65-70% solutions that require less capacity.

Dairy. In the production of bakery products, the following dairy products are used: milk, cream, sour cream, cottage cheese and whey. Natural dairy products are perishable raw materials, so they are stored at a low temperature. The lower the temperature, the longer the shelf life can be.

Milk, cream and sour cream for the production of bread cannot be frozen, as this violates the consistency and changes the taste. These products are stored in metal cans at a temperature of 0-8°C. Sour cream can be stored at this temperature for up to 3 days. Milk at a temperature of 8-10°C is stored for 6-12 hours, and at a temperature of 6-8°C - 12-18 hours. The shelf life of cottage cheese at a temperature of 0°C is 7 days, in a frozen state - 4-6 months.

Condensed milk in an unsealed container is stored at a temperature of 8 ° C for up to 8 months. You cannot freeze it.

In unsealed containers, they are stored at the factory for up to 3 months.

Powdered milk is gradually diluted in water at a temperature of 28-30 ° C to the moisture content of natural milk (700-800 ml of water per 100 g of powdered milk) with constant stirring of the mass, after which it is left to swell for 1 hour. Good results are obtained when prepared for production of an emulsion from powdered milk, water and fat in a special installation or churning machine. In an emulsion, milk swells well, and fat is crushed. In addition, the emulsion has a positive effect on the quality of products during production. The emulsion should be passed through a sieve with cells with a diameter of not more than 2 mm.

All liquid dairy products for the production of bread and bakery products, when preparing for use, are poured from a can into a production container and filtered through a sieve with cells up to 2 mm in diameter.

Whey is a by-product of the production of cottage cheese or cheese. It is a homogeneous liquid of a greenish color, with a specific smell and taste.

Milk natural whey is delivered to bakeries in tank trucks, from where it is then pumped into special containers with a cooling jacket.

Fats. In the baking industry, cow butter, margarine, special baking fats and vegetable oil are most widely used in the production.

Cow butter is divided into butter and ghee. Butter is prepared in the churning or in-line process from pasteurized sweet cream or from cream that has been fermented beforehand. Humidity butter 16-20%, fat content 72.5-82.5 (including the moisture content of unsalted butter - 16, peasant - 20%). Humidity of ghee 1%; fat content 98%. Ghee is obtained by melting combined butter at a temperature of 75-80°C.

Butter in production should be stored in a cold, dark room. Under the action of light, atmospheric oxygen and elevated temperature, the oil goes rancid. Butter is stored at a temperature not exceeding 8 ° C for up to 3 months, frozen butter - up to 12 months.

Margarine is a specially prepared fat that resembles butter in chemical composition, energy value and digestibility. For the production of margarine, a fat base (a set of fats), fermented milk, emulsifiers, dyes, flavors and other auxiliary materials are used.

The fat base of margarine consists of lard (65-75%) and natural fats (and animals).

For the storage of hard margarine, the following terms are established:

- Liquid margarine for production is stored in oval-shaped stainless steel tanks with a water jacket at a temperature of 35-48°C for no more than 2 days. Propeller agitators are provided in each tank, the periodic rotation of which prevents the separation of the margarine emulsion.

- Confectionery, baking, and cooking fats are anhydrous fats primarily composed of tallow, with or without the addition of small amounts of natural fats and emulsifiers. In the baking industry, fat with phosphatides (solid consistency) and liquid fat, which has a mobile consistency, are used at a temperature of 15-20°C.

- Confectionery and baking fats are stored for 1-9 months, depending on the temperature (from -10 to +15°C) and the presence of antioxidants (antioxidant) in the production recipe.

During preparation, solid fats are freed from containers, inspected, and the surface is cleaned of contaminants. Then the fats are cut into pieces and the internal state of the fat is checked.

For the production of vegetable oils, oilseeds are used by pressing and extraction, and more often by a combined production method.

Vegetable oils are stored in a dark, cool room, in closed containers (barrels or tanks) at a temperature of 4-6°C. Under the influence of atmospheric oxygen, light and elevated temperature, vegetable oils deteriorate.

The main technological stages of bakery production

The technological process of making bread consists of the following stages: kneading dough and other semi-finished products, fermentation of semi-finished products, dividing the dough into pieces of a certain mass, forming and proofing dough pieces, baking, cooling and storing bread products.

Kneading and dough formation

Bread dough kneading is the most important technological operation of production, on which the further course of the technological process and product quality largely depend. When kneading dough from flour, water, yeast, salt and other components, a homogeneous mass with a certain structure and physical properties is obtained.

Loosening and fermentation of dough

In order for the baked product to be porous and easily digestible, the dough must be loosened before baking bread. This is a prerequisite for a good baked dough.

The dough begins to ferment under the action of carbon dioxide, which makes it possible to obtain bread with a well-loose porous crumb. The purpose of dough and dough fermentation is to bring the dough to a state in which it will be best prepared for cutting and baking in terms of gas-forming ability and structural and mechanical properties. At the same time, the accumulation in the dough of substances that determine the taste and aroma characteristic of bread from well-fermented dough is no less important.

Preparing wheat dough

Dough preparation is the most important and longest operation in the production of bread, taking up about 70% of the time of the production cycle. When choosing a specific method of dough preparation, first of all, the produced assortment of products, as well as other production data, are taken into account.

It is customary to distinguish between traditional methods of making dough for bread, new progressive ones. Traditional technology provides for a long fermentation of semi-finished products, a total of 4.5-7 hours. Progressive (accelerated) technology is characterized by a reduction in the dough preparation cycle. At present, about 70% of the total mass of products is prepared using advanced technology, simpler and more economical.

The list and ratio of certain types of raw materials used in the production of a certain type of bread is called a recipe.

The recipe for the production of bread, which indicates the type of flour and the amount of additional raw materials, except for water, is approved by higher organizations (department, ministry). In the recipes, the amount of basic and additional raw materials is usually expressed in kg per 100 kg of flour.

Together with the recipe, a technological instruction is approved, which indicates the method of preparing dough for bread and the technological regime (fermentation duration, acidity of semi-finished products, baking conditions for the product, etc.) However, this documentation does not reflect the specific production conditions of each enterprise: the capacity of the baking oven, the quality of flour, others

Taking into account these and other production conditions, the laboratory of the enterprise creates specific recipes for the production of bread. The production recipe indicates the mass of flour, water, salt solution and the mass of other components necessary for kneading each semi-finished product (dough, dough, etc.). The consumption of raw materials for kneading dough according to the production recipe must strictly comply with the recipe data on

The recipes for the production of a number of varieties of bread and bakery products also provide for other types of additional raw materials (eggs, raisins, milk, whey, skimmed milk powder, poppy seeds, etc.). It follows from this that the list and ratio of raw materials in the dough for different types and varieties of bread products may be different.

With continuous kneading of dough for bread, the production recipe is based on the minute operation of the dough mixer, with periodic kneading, based on one portion of the dough (bowl).

The calculation of the recipe for the production of bread in both cases is fundamentally the same. First, the total amount of flour for kneading the dough is calculated, and then the amount of flour required for the preparation of other semi-finished products (dough for bread, sourdough, etc.). After that, a dough or sourdough recipe is made, and then a dough recipe.

When compiling a recipe for the production of bread, it must be remembered that the amount of each type of raw material (yeast, salt, etc.) is calculated for the total flour content in the dough, regardless of which semi-finished product (dough, sourdough) this raw material will be added to. The flour used to make liquid yeast, tea leaves and other semi-finished products is included in the total mass of flour.

Currently, there are two main ways to prepare wheat dough for bread production. This is a paired (two-phase) and non-paired (single-phase) method.

Preparing dough for dough

The most common method of preparing dough for the production of bread is the sponge method, in which the first phase of dough preparation is sponge. Opara is a semi-finished product obtained from flour, water and yeast by kneading and fermentation. Ready dough is completely consumed for the preparation of the dough.

To prepare bread dough, take part of the total mass of flour (30-70%), most of the water and the entire amount of yeast. After 3-5 hours of fermentation on the dough, the dough is kneaded, which ferments for 30-120 minutes.

The technology for preparing dough for bread production depends on the type of flour, its baking properties, product recipes and many other factors.

In the production of wheat bread, the moisture content of dough should be 41-47%, bakery products - 44-46%, which is explained by the different norms of dough moisture for these products. When processing weak flour, the moisture content of the dough is reduced to delay the relaxation of the gluten. If the gluten of the flour is short-tearing, the moisture content of the dough for bread production is increased by 2-3%.

The amount of pressed yeast for making sourdough (according to the recipe) is 0.5-4%. The highest dose of yeast in dough for rich dough is 2-4%, for bread dough - 0.5-0.7%.

The temperature of the dough for the production of bread, as a rule, is somewhat lower than the temperature of the dough (28-29°C). This temperature is most favorable for the reproduction of yeast cells.

Salt and fats are not added to the dough for the production of bread, as these substances adversely affect the yeast. The moisture content of the dough is 1-3% higher than the moisture content of the dough, which improves the metabolism in the yeast cell, activates enzymes and accelerates the swelling of gluten. Prolonged fermentation of dough (3-5 hours) ensures sufficient reproduction of yeast and accumulation of maturation products.

The dough for the production of bread on a dough is prepared in the following ways: traditional on a dough containing 50% of flour from its total mass in the dough; a large dough containing 65-70% of the total amount of flour of its total mass in the dough; liquid dough containing 27-30% flour of its total mass in the dough.

The traditional method of preparing dough on dough is used in the production of various bread, bakery and fancy products.

Dough for the production of bread is prepared from 45-50% flour, most of the water and the entire amount of yeast required by the recipe. The technology for making sourdough depends on the baking properties of flour and other reasons. If the flour is weak, reduce the humidity and temperature of the dough compared to the norms, increase the flour content in the dough to 60%. The dosage of pressed yeast for bakery products is 0.5-1.5% by weight of flour, liquid - 20-25%.

When preparing dough for the production of bread, in machines with rolling bowls, the required amount of water is measured into an empty bowl, a yeast suspension is added, the dough mixer is turned on, and flour is added with continuous stirring. The kneading of the dough until a homogeneous mass is carried out on the "Standard" machine for 5-6 minutes. .

When kneading dough (and dough) for bread, the bowl should be covered with a lid. The kneaded dough is sprinkled on top (flashed) with flour to prevent airing, and left to ferment for 3-5 hours. The readiness of the dough in production is determined organoleptically and by acidity. The fermented dough has a sharp alcohol smell and a uniformly mesh structure, which indicates the formation of a normal gluten framework in it. The volume of dough for the production of bread at the end of fermentation increases by 2-2.5 times, with a slight pressure on the surface of the dough, it falls off. The fall of the dough coincides with the formation of the greatest amount of yeast in it and their greatest activity.

The dough for the production of bread on a dough is kneaded for 6-8 minutes. When kneading, water, a solution of salt, sugar, fat and other raw materials are added to the finished dough, and then flour is poured while stirring the mass. Flour should be added gradually, but in one go. Adding flour or water to the kneaded dough is not recommended. During the initial kneading, the gluten is already swollen, so it does not absorb a new portion of water well (the dough becomes sticky). Adding flour to the resulting dough can cause a mess at the bottom of the bowl. The quality of the flour for production and the temperature of the room affect the initial temperature of the dough, which can be 29-32°C. The dough on the dough ferments for 1-2 hours, depending on the type of product, the quality of the flour and other factors.

In the process of fermentation, it is recommended to knead the dough from flour I and premium (especially strong flour). Knockdown is repeated mixing of the dough for 1-2 minutes during the fermentation period in order to remove fermentation products and improve the structure. Warming up in production is done 50-60 minutes after kneading the dough.

Cooking wheat dough in a steamless way

The single-phase method consists in the fact that the dough is kneaded in one step from the entire amount of raw materials and water put according to the recipe, without adding any fermented semi-finished products (dough, starter).

The dough is prepared with a high consumption of yeast (1.5-2.5% of the total mass of flour). The increase in yeast consumption is explained by the fact that worse conditions are created for their vital activity in the dough than in the dough (thick environment, the presence of salt, etc.).

An increase in the dose of yeast is also necessary to loosen the dough of the future bread in a relatively short time (2-3 hours).

In production, in order to reduce the consumption of yeast and improve the taste properties of the product, yeast is usually activated before kneading the doughless dough. The initial temperature of the dough is 29-31°C, the duration of fermentation is 2.5-3 hours. It is recommended to punch the dough 50-60 minutes after kneading. The kneading during the preparation of a doughless dough is of greater technological importance than for a dough prepared on a dough. It should be noted that the dough for the production of bread, prepared by the non-dough method, contains less acids, aroma-forming and flavoring substances than the dough prepared with the dough. Fermentation, colloidal and biochemical processes proceed less intensively in a non-dough dough due to the thick consistency of the dough and the reduced fermentation cycle.

The steamless method is often used in the production of bread, bakery and fancy products from wheat flour of I and premium grades. The dough is prepared in a bezopare way in dough mixing machines with rolling bowls (machine "Standard", T1-KhT2-A) or using a RZ-KhTI machine.

Cutting the finished dough

In the production of wheat bread and bakery products, dough cutting includes the following operations: dividing the dough into pieces, rounding, preliminary proofing, shaping and final proofing of dough pieces.

The division of the dough into pieces is carried out in dough dividing machines. The mass of a piece of dough is set based on the given mass of a piece of bread or bakery products, taking into account the loss in mass of a piece of dough during its baking (upek) and a piece of bread during cooling and storage (shrinkage).

After the dough dividing machine, the dough enters the rounding machines, where they are given a round shape. After that, the dough piece should rest for 3-8 minutes to restore the gluten carcass, after which it goes to the molding machine, where it is given a certain shape (loaves, baton, rolls, etc.).

bread baking

Baking is the final stage in the production of bakery products, which finally forms the quality of bread. During the baking process, microbiological, biochemical, physical and colloidal processes simultaneously occur inside the dough piece.

All changes and processes that turn the dough into finished bread occur as a result of heating the dough piece.

Bread products are baked in the baking chamber of baking ovens at a steam-air temperature of 200-280°C. Baking 1 kg of bread requires about 293-544 kJ. This heat is spent mainly on the evaporation of moisture from the dough piece and on its heating to a temperature (96-97 ° C in the center), at which the dough turns into bread. A large proportion of heat (80-85%) is transferred to the dough by radiation from the hot walls and vaults of the baking chamber.

Dough blanks for production are heated gradually, starting from the surface, so all the processes characteristic of baking bread do not occur simultaneously in its entire mass, but in layers, first in the outer, and then in the inner layers. The speed of heating the dough, bread in general, and, consequently, the duration of baking depends on a number of factors. With an increase in temperature in the baking chamber (within certain limits), the heating of the workpieces is accelerated and the baking time is reduced.

The formation of a hard bread crust during the production process occurs as a result of dehydration of the outer layers of the dough piece. A hard crust stops the increase in the volume of dough and bread, so the crust should not form immediately, but 6-8 minutes after the start of baking, when the maximum volume of the workpiece has already been reached.

Biochemical processes take place in the surface layer of the workpiece and in the crust: starch gelatinization and dextrinization, protein denaturation, the formation of aromatic and dark-colored substances, and the removal of moisture. In the first minutes of production (baking) of bread, as a result of steam condensation, starch on the surface of the workpiece gelatinizes, partially turning into soluble starch and dextrins. The liquid mass of soluble starch and dextrins fills the pores on the surface of the workpiece, smooths out small irregularities and, after dehydration, gives the crust a shine and gloss.

Denaturation (coagulation) of protein substances on the surface of the product occurs at a temperature of 70-90°C. The coagulation of proteins, along with the dehydration of the top layer, contributes to the formation of a dense, inelastic bread crust.

The coloring of the crust of bread during production in light brown or brown is due to the following processes:

- caramelization of dough sugars, in which brown products (caramel) are formed;

- a reaction between amino acids and sugars, in which aromatic and dark-colored substances (melanoidins) accumulate.

The color of the crust of bread and products during production depends on the sugar and amino acid content of the dough, on the duration of baking and on the temperature in the baking chamber. For normal coloring of the crust in the dough (by the time of baking) there must be at least 2-3% sugar to the mass of flour. Aromatic substances (mainly aldehydes) from the crust penetrate into the crumb, improving the taste properties of the product. If the above processes are carried out properly, then the baked bread crust is smooth, shiny, evenly colored light brown. The specific content of crusts (in % by weight of the product) is 20-40%. The smaller the mass of the product, the higher the percentage of crusts.

When baking inside the dough piece, the fermentation microflora is suppressed, the activity of enzymes changes, starch gelatinization and thermal denaturation of proteins occur, the humidity and temperature of the inner layers of dough-bread change.

The vital activity of the fermentative microflora of the dough (yeast cells and acid-forming bacteria) changes as the piece of dough-bread is heated during the baking process.

Yeast cells, when the dough is heated to about 35 ° C, accelerate the process of fermentation and gas formation to the maximum. Up to about 40°C, the vital activity of the yeast in the baked piece of dough is still very intense. When bread dough is heated above 45° C., the gas formation caused by yeast is drastically reduced.

At a dough temperature of about 50 ° C, the yeast dies off.

The vital activity of the acid-forming microflora of the dough, as the dough warms up, is first forced, after reaching a temperature above the optimum for their vital activity, it slows down, and then completely stops.

The moisture content of the hot bread crumb (in general) in production increases compared to the moisture content of the dough due to moisture transferred from the upper layer-blank. Due to the lack of moisture, starch gelatinization proceeds slowly and ends only when the central layer of dough-bread is heated to a temperature of 96-98°C. Above this value, the temperature in the central layers of the crumb does not rise, since the crumb contains a lot of moisture and the heat supplied to it will be spent on its evaporation, and not on heating the mass. When baking rye bread, not only gelatinization occurs, but also acid hydrolysis of a certain amount of starch, which increases the content of dextrins and sugars in dough-bread. Moderate hydrolysis of starch improves bread quality.

The change in the state of protein substances begins at a temperature of 50-75°C and ends at a temperature of about 90°C. Protein substances in the process of baking (production) of bread undergo thermal denaturation (coagulation). At the same time, they compact and release the moisture absorbed by them during the formation of the dough. Coagulated proteins fix (fix) the porous structure of the crumb and the shape of the product. In the product, a protein frame is formed, in which grains of swollen starch are interspersed. After thermal denaturation of proteins in the outer layers of the product, the increase in the volume of the workpiece stops.

The volume of the baked product is 10-30% more than the volume of the dough piece before placing it in the oven. The increase in volume during production occurs mainly in the first minutes of baking as a result of residual alcoholic fermentation, the transition of alcohol to a vapor state at a temperature of 79 ° C, as well as thermal expansion of vapors and gases in the dough piece. Increasing the volume of dough-bread improves the appearance, porosity and digestibility of the product.

Currently, dead-end cradle-hearth furnaces with duct heating (FTL-2, FTL-20, KhPP, etc.) are most widely used.

The temperature in the baking chamber for the production of bread is regulated by changing the intensity of combustion of the fuel. In gas-fired ovens, the gas and air supply to the burners is increased to raise the temperature. When coal is burned, the blast is increased and more often fuel is thrown onto the grate. In ovens with duct heating, gates are installed in gas ducts to control the temperature in certain sections of the baking chamber. With the help of a gate, the amount of hot fuel combustion products entering the corresponding channel is changed. The easiest way to control the temperature in electrically heated bread ovens is by turning on or off some of the electric heaters located above and below the hearth of the oven.

Determination of the readiness of bread

The correct determination of the readiness of bread in the production process (baking) is of great importance. Its quality depends on the correct determination of the readiness of bread: the thickness and color of the crust and the physical properties of the crumb - elasticity and dryness to the touch. Excessive baking time increases baking time, reduces productivity, and causes excessive fuel consumption. An objective indicator of the readiness of bread and bakery products is the temperature in the center of the crumb, which at the end of baking should be 96-97°C.

In production, the readiness of products is still determined organoleptically according to the following criteria:

- peel color (color should be light brown);

- the state of the crumb (the crumb of the finished bread should be relatively dry and elastic). Determining the state of the crumb, hot bread is broken (avoiding crushing) and lightly crushed with fingers on the crumb in the central part. The state of the crumb is the main sign of the readiness of bread;

- relative weight (the mass of the baked product is less than the mass of the unfinished product, due to the difference in packaging).

The readiness of bread can also be determined by the temperature in the center of the crumb at the moment the bread comes out of the oven using a thermometer.

In order to avoid damage to the thermometer when it is introduced into the bread, it is recommended to first make a puncture in the crust with some sharp object, the diameter of which would not exceed the diameter of the thermometer.

The length of the end of the thermometer inserted into the bread should be set in advance. Refinement of the point of introduction of the thermometer into the bread is carried out with each determination.

To measure the temperature of bread in production, the thermometer must be preheated to a temperature 5-7°C below the expected temperature of the bread (preheating can be done in another loaf of bread). This is done to prevent the crumb from cooling and to overcome the inertia of the meter. It is necessary that the rise of mercury in the thermometer occurs for no more than 1 min.

Before checking the baked bread according to its temperature, it is necessary to experimentally establish the temperature of the bread crumb corresponding to the baked bread at this enterprise.

Typically, the temperature of the center of the crumb, which characterizes the readiness of rye pan bread, should be about 96°C, wheat - about 97°C.

The experimentally established temperature of the bread, which characterizes its readiness, can be used to control the readiness of the bread and the size of the bread.

Storage and transportation of bread

Baked bread cools during storage and loses mass due to shrinkage and staleness. These two processes are independent, but they are somewhat dependent on each other, since the crumb of bread, which has lost a certain amount of moisture, partially loses its softness not only due to the staling process, but also due to a decrease in moisture.

The stacking of finished products after they leave the oven and the storage of products until they are released to the distribution network are the last stage of the bread production process and are carried out in the bakeries of enterprises. The capacity of grain storage facilities is usually calculated taking into account the storage of shift production, and when working in 2 shifts, taking into account one and a half shift work.

In the storage facility, accounting for finished products, their sorting and organoleptic evaluation according to a point system are carried out. Before the release of products to the distribution network, each batch of products is subject to mandatory inspection by a rejector or a person authorized by the administration.

Brakerage as a means of fighting for the sale of good quality products to the trade network is mandatory for all bakery enterprises that produce bread, bakery, lamb and crackers. According to the current regulation, the maximum number of points for quality indicators is 10.

The rules for laying, storing and transporting bread products are determined by GOST 8227-56.

In production, products after baking are placed in wooden trays, the dimensions of which are determined by GOST 11354-82 “Reusable plank and plywood boxes for food products”.

Shaped bread is placed on the side or bottom side, hearth bread, rolls, loaves - in 1 row on the bottom side or rib, fancy products - in 1 row flat. Trays with bread (14-28 pieces) are placed on mobile trolleys, which are taken to the loading area as necessary.

Ways to reduce costs and losses in production + Useful video

To ensure the economical consumption of raw materials for the production of bread at enterprises, it is necessary to exercise the strictest control over the quantitative indicators of the technological process - costs and losses.

High costs and losses in production indicate shortcomings in the organization and conduct of the production process, the elimination of which leads to more economical consumption of raw materials for bread.

The industry has a number of ready-made solutions and techniques that allow more economical use of raw materials in the production of bread and bakery products.

The introduction of bulk installations for the storage of flour and its transportation in flour trucks can not only eliminate heavy manual labor, eliminate the use of bags, but also significantly reduce losses. In this case, flour savings will be up to 0.1% of its total amount.

At enterprises with container storage of flour for the production of bread, its losses for spraying can be reduced by installing aspiration devices; it is advisable to install vacuum cleaners in flour warehouses.

In recent years, self-shaking filters with an electric drive have become widespread.

The cost of DM for fermentation in the traditional sponge method of bread production is on average 2.5-3.3% by weight of flour.

The introduction of progressive schemes for testing on liquid dough, thick large dough or the use of an accelerated method reduces these costs to 1%.

Hot bread does not have the same cooling conditions for all products. These conditions depend on the extent to which the expedition is loaded with bread, the operation of ventilation devices, the season, the temperature of the room, the location of bread in the trays of the trolleys, including the height from the floor, the capacity of the trolleys, the density of the bread stacking, and a number of other reasons. It follows from the foregoing that the mass of piece bread depends on the combination of the above conditions. Most often, piece bread entering the distribution network has a mass greater than that established by the state standard. Thus, enterprises, to some extent, protect themselves from making claims regarding the production (output) of products with a mass less than the prescribed standard. Along with this, the systematic excess of the mass of products leads to a decrease in the yield of bread.

To reduce deviations in the mass of piece bread, it is recommended to increase the accuracy of dough cutting machines, monitor the temperature of the ovens and use special cooling devices that ensure uniform drying of bread during storage.

The main difficulty in the mechanized production of bread is the sticking of dough to the working surfaces of dough cutting lines, conveyor belts, and proofer covers. To eliminate sticking of the dough to the equipment, the working bodies of rounders, dough rolling machines, as well as covers for proofing boards and conveyor belts are sprinkled with flour, for which up to 1% of the total mass of processed flour is consumed. The use of flour for this purpose worsens the sanitary condition of the workshop and reduces the yield of products.

The experience of the country's bakery enterprises has shown that the processing of dough cutting lines and proofing devices with water-repellent, polymeric materials helps to reduce the cost of flour in production when cutting dough.

When processing conveyor belts, the tester of the cutting line, with polymer coatings in combination with blowing with warm air, flour is not used when cutting dough.

When blown with air, a thin, relatively dry film is created on the surface of a piece of bread dough, which, in combination with release coatings, eliminates adhesion. Products prepared on a dough cutting line treated with anti-adhesive materials have a better appearance, a smoother surface with a bright color.

The introduction of polymeric materials into production improves the sanitary condition of workshops, reduces air pollution with flour dust, and also reduces the consumption of flour for filling. At the same time, the work of workers is facilitated, the culture of production is raised and the quality of products is improved.

Fluctuations in the moisture content of dough for bread production are usually caused by deviations in the mass of flour coming from the auto flourer, the amount of water, salt solution, yeast suspension and other additional raw materials dosed by the appropriate equipment when kneading the dough.

Reducing the moisture content of the dough against the established norm by 1% leads to a decrease in the yield of bread from wheat flour of I and II grades by 2-2.5%, and rye - by 2.5-3%. Therefore, it is recommended in production to systematically, at least 2 times per shift, control the operation of dosing devices, as well as the humidity of the dough.

The accuracy of dough cutting equipment has a significant impact on flour savings. Therefore, when producing piece bread, it is necessary to systematically check the operation of dough dividers and avoid deviations in the mass of pieces of dough from the established one.

A feature of the production of piece products is that their mass is determined by dividing the dough into pieces, which is carried out long before the end of the technological process of making bread. After dividing the dough, baking of bread blanks and cooling of bread follow, changing the mass of finished products.

The subsequent adjustment of the mass during the sale of bread to the trading network, according to the conditions of the technology, can no longer be made. Consequently, the mass of piece bread products is determined not only by the accuracy of the dough divider, but also depends to a greater extent on the conditions for performing subsequent operations of the production technology.

A large proportion of the cost is upek bakery products. In order to save grain resources, it is necessary not only to reduce the upek, but also to level it on the cradle or the hearth of the oven. One of the ways to equalize the baking of bread can be the shielding of heating surfaces in the oven by laying asbestos sheets in places with excessive heat transfer. To improve the heat supply to the upper gas pipeline, it is necessary to carefully and systematically clean it from ash and regulate the gas flow using gate valves provided for in the design of the production furnace.

To reduce the baking of bread, it is advisable to use water spraying of dough pieces or finished products when leaving the oven.

When baking bread and products, in addition to moistening the dough pieces, it is necessary to moisten the environment of the baking chamber. Steam consumption in this case should be approximately 200-250 kg per 1 ton of products.

Very helpful video:

These measures to reduce the baking time of bread products are widely used in the production of many bakery enterprises and give a positive economic effect.

- Capital investments: 1 123 100 rubles,

- Average monthly revenue: 535,000 rubles,

- Net profit: 57,318 rubles,

- Payback: 23 months.

A feasibility study for opening a business in the field of food production - a mini-bakery, which can be used as a model for writing a business plan, as well as an example for calculating the economic feasibility of starting a business.

Target: Justification of the feasibility and effectiveness of organizing a business for baking bakery products.

Project description

Project idea: mini-bakery

The idea is to open a mini-bakery specializing in baking bakery products in the city of "N" (population 270 thousand people).

Range.

Planned range:

- Butter buns (8 types)

- cupcakes

- Bagel products

- Bagels

- cottage cheese

Competition

Currently, in the city of "N" there are 2 bakeries and 3 mini-bakeries, all of which specialize in the production of bread products (bread).

In this regard, the mini-bakery to be opened will specialize in the production of bakery products (100% assortment). The main competitive advantage is the sale of only fresh baked goods.

Organizational form and system of taxation.

Organizational and legal form of doing business: "individual entrepreneur". Form of taxation: Simplified taxation system, income minus expenses, 15%. Accounting: At the initial stage, tax and accounting will be outsourced to a specialized accounting firm. After organizing all production processes, debugging sales, the owner of the business will keep records independently using the My Business online service.

Working mode:

The bakery will be open daily.

From 00:00 to 10:00 for employees (baker, assistant) directly involved in baking bakery products. This category of employees will work in shifts, two after two.

From 7:30 to 16:30 for employees (manager, sales representative) who are engaged in the sale and sale of finished products. This category of employees will work for a 5-day work week, and the weekends will come out alternately.

General staffing:

Required equipment.

To organize a business, the following set of equipment for a packer is required:

| Name | Qty. | Price | |

| Baking oven HPE-500 | 1 | 34794 rub. | |

| Proofer ShRE 2.1 | 1 | 19760 rub. | |

| Flour sifter PVG-600M | 1 | 21708 rub. | |

| Dough mixer MTM-65MNA | 1 | 51110 rub. | |

| Hearth LEAF for HPE 700x460 | 20 | 584 rub. | |

| Umbrella 10x8 | 1 | 7695 rub. | |

| Single-section washing bath | 1 | 2836 rub. | |

| Two-section washing bath VM 2/4 e | 1 | 5744 rub. | |

| Refrigerated CABINET R700M | 1 | 24420 rub. | |

| Confectionery table SP-311/2008 | 1 | 13790 rub. | |

| Wall food table SPP 15/6 | 1 | 3905 rub. | |

| Portion scales CAS SW-1-5 | 1 | 2466 rub. | |

| Portion scales CAS SW-1-20 | 1 | 2474 rub. | |

| Rack SK | 1 | 6706 rub. | |

| Cart hairpin to HPE TS-R-16 | 1 | 17195 rub. | |

| Total expenses for the purchase of bakery equipment: | 226283 rubles | ||

|---|---|---|---|

Sales channels

Main distribution channel: small retail stores located in the city of "N" and nearby communities. Sales through network (regional and federal) grocery stores in 2013 are not planned.

Project Implementation Plan

Calendar plan

According to the calendar business plan of the mini bakery, the company's launch period is 2 months. All stages associated with the opening of activities are in the area of responsibility of the business owner.

| Stage name | Mar.13 | ||||||

|---|---|---|---|---|---|---|---|

| 1 decade | 2nd decade | 3rd decade | 1 decade | 2nd decade | 3rd decade | 1 decade | |

| 1 Registration of activities in the Federal Tax Service, print order | |||||||

| 2 Opening a current account | |||||||

| 3 Conclusion of a lease agreement for the production workshop | |||||||

| 4 Payment for equipment (baking line, car, inventory) | |||||||

| 5 Repair of the premises in accordance with the requirements of the SES for food production, connection to the power grid, other expenses | |||||||

| 6 Coordination with SES shop premises | |||||||

| 7 Line installation, installation supervision, commissioning, trial baking | |||||||

| 8 Coordination with Rospotrebnadzor of recipes, specifications and instructions for manufactured products. | |||||||

| 9 Recruitment | |||||||

| 10 Conclusion of an agreement with suppliers and buyers | |||||||

| 11 Getting Started | |||||||

The total cost estimate for the implementation of the project:

| Item of expenses | Amount of expenses, rub. | Note |

|---|---|---|

| Registration of activities in the IFTS | 15 000 | State duty, printing order, opening a bank account, other |

| Cosmetic repairs of the premises, bringing the premises in accordance with the requirements of the SES | 100 000 | - |

| Acquisition of equipment for baking bakery products | 223 104 | - |

| Purchase of vehicles | 450 000 | Bread van for 128 trays on the base, car GAZ-3302, 2010 |

| Acquisition of tableware | 30 000 | - |

| Recruitment (advertising) | 5 000 | - |

| Create inventory | 50 000 | - |

| Working capital (financing activities before reaching payback) | 150 000 | - |

| other expenses | 100 000 | Connection to power grids, approval of technical specifications and technical specifications for products |

| Total | 1 123 104 |

According to the calculations, investments in the amount of 1.1 million rubles are required to open a business.

Planned financial performance indicators.

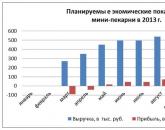

Planned revenue and profit for 2013-2014.

According to the organizational plan, the start of the company's activities is scheduled for March 2013, and self-sufficiency is expected in May 2013.

The company's activity is seasonal, the peak of sales falls on the period September-November and March-April, in the remaining months there is a seasonal decrease in revenue.

Expenditure part.

The cost part of the bakery activity includes the following expenses:

- The cost of manufacturing products. This line includes the cost of purchasing flour, yeast, margarine, sugar and other ingredients.

- Variable expenses. Wages of employees based on output (12% of revenue)

- General expenses: This group of expenses includes expenses for wages of employees (a fixed part), social contributions, rent for the workshop premises, fuel and lubricants, machine repairs, utility bills, administrative expenses, accounting expenses, as well as other expenses.

Planned distribution structure of funds received from buyers for 2013-2014

| Expenditure | ||||

| The cost of manufacturing products | ||||

| The salary of employees is a variable part (depends on output) | ||||

| fixed costs | ||||

| Profit before tax | ||||

Calculation of return on investment.

- Project start: January 2013

- Start of operation: March 2013

- Reaching operational break-even: May 2013

- Achievement of forecast revenue: June 2013

- Payback date of the project: November 2014

- Payback period of the project: 23 months.

Opening risk analysis

The process of implementation and further operation of the project may be complicated by a number of risks and negative factors, which are given in the analysis of risk factors and opportunities for the operation of a mini-bakery. To determine the degree of influence of these risks and their danger to business, we will conduct a qualitative and quantitative analysis.

Qualitative indicators are determined by an expert assessment of the likelihood of a threat. Quantitative analysis shows the degree of impact of risks in actual terms.

Qualitative project risk analysis

The entire risk zone is divided into external, where the impact of the general economic situation and events not related to the business management process is especially noticeable, and internal, which directly depends on the effectiveness of the organization of management and business implementation.

Table 1. The main external risks of the project

| Name of risk | Risk assessment | Risk Characterization and Responses |

|---|---|---|

| Raw material cost increase | The risk will lead to an increase in the cost of production and a decrease in the marginal part of the income. Risk compensation occurs by increasing the selling price of products or by revising the weight requirements. To level the risk, it is necessary to constantly monitor the supplier market and conclude long-term contracts. |

|

| Opening N direct competitors in the city | When direct competitors appear, the existing market capacity is proportionally divided into participants, which leads to a decrease in sales. To overcome the risk at the organizational stage, it is necessary to conduct a policy of detuning from competitors, maintain consumer loyalty. |

|

| Seasonal decline in sales | The risk entails a decrease in the average annual sales figures, increases the cost of maintaining staff, and leads to fluctuations in the intensity of the use of production equipment. The risk is leveled by a competent advertising and organizational policy. |

|

| Change at the state level of regulatory requirements for bakery products | The risk may lead to a revision of the production flow charts and assortment base. |

All external risks can be mitigated by developing a crisis management strategy at the organizational stage of the business, maintaining competent positioning and constant contact with the buyer.

Table 2. Main internal risks of the project

Quantitative risk analysis of the project

All external and internal risks have a single negative consequence - a decrease in profits. The reasons for the decrease in profits can be:

- an increase in the raw material cost of production due to an increase in prices for materials, raw materials, labor;

- opening direct competitors who will be able to win their own market share;

- decrease in consumer demand due to unsatisfactory quality and service, as well as seasonal.

A quantitative analysis of investment risks can be carried out using the sensitivity analysis method using the internal rate of return (NPV) as the main parameter. However, having experience data specific to a particular market (city N with a population of 270,000), we use the method of practical calculation.

The degree of impact of the increase in raw materials cost and increase in selling price

Calculated by calculating the elasticity of demand. With an average cost of products (buns (8 types), muffins, lamb products, bagels, cottage cheese) within the range of 19-23 rubles, an increase in the final price will have the following indicators:

Thus, we see that with a low average cost of products, a rise in price may lead to a slight increase in demand (due to consumer expectations), and a rise in price by 20-25% (a significant increase in commodity prices that do not fit into the framework of annual inflation) will lead to loss of an average of 4.5% of buyers. The risk has a low quantitative value.

The degree of influence of the competitive environment

To calculate the degree of influence of competition, it is necessary to conduct a detailed analysis of the competitive environment and calculate the market share of each operator. The emergence of a new player always entails a redistribution of shares, at the first stage this happens at the expense of the weakest representatives of the industry. In our case, the project involves the use of contractors (distribution channels - small retail stores located in the city of "N" and nearby settlements), which protects against direct exposure to a competitor under long-term and strict contractual conditions (exclusive partnership).

With a total market share of 6%, the degree of influence of a new competitor has a relative share of 1.2% - this is how much a mini-bakery can lose when opening a similar enterprise in the sales area.

Degree of influence of seasonality and level of service

Taking into account the average seasonal decline in the sale of bakery products in the summer within 10-15%, and the main requirements of buyers for products,

Project Risk Ranking

The most probable are the marketing and seasonal risks of a decrease in demand, which may be initiated by an increase in the cost of raw materials and the opening of direct competitors. These are the most critical threats, which should be anticipated at the stage of organizing and implementing a business idea.

The relevance of the mini-bakery business plan

General trends

To date, the bakery market in Russia has not yet been established due to the revaluation of values and the general trend of environmentally friendly and healthy food. Over the past ten years, traditional varieties of bread and bakery products have significantly given way to recipes borrowed from the West: croissants, baguettes, croutons, ciabatta, cereal bread and much more. Habitual tin bread, capital loaf, rye and Darnitsa, Moscow, bran and Borodinsky, as well as other varieties produced by municipal bakeries, have lost their top positions, and now the distribution of consumer attention falls in equal shares on traditional offers and borrowed ones (52% to 48%):

Dynamics of growth in consumption of bread varieties

Dynamics of growth in consumption of bread varieties

i.e., if back in 1970 Western trends had little influence on the choice of buyers who preferred Soviet-made products, then since the 1990s there has been an increase in the influence of Western technologies and the emerging commercial competition, which has significantly expanded the range of bakery products. By the 2000s, traditional breads had lost more than half of the market. This is largely due to the transition of post-Soviet industries into private hands, which picked up the trend and began to produce fashionable and sought-after products.

| 1970 | 1995 | 2000 | 2010 | 2013 | |

|---|---|---|---|---|---|

| Traditional varieties | |||||

| Borrowed |

By 2010, the growth dynamics had slowed down, the consumer began to lose interest in foreign formulations. In addition, the state policy to support national values also influenced the formation of a relative balance: now there is an equality in the assortment choice between tradition (familiar varieties) and borrowing. As for the bakery group, the trends here are similar.

The main trend of the market of bread and bakery products in the current period is healthy food, freshness, naturalness. Own bakeries at supermarkets have gained great popularity, where aroma marketing works perfectly: the smell of fresh baked goods ensures high sales. Traditional factory bakeries are popular with the older generation due to their habitual mode of operation and assortment.

According to the Information and Information Center Informkonditer, Russians most often buy bakery products at specialized outlets (branded bakery shops, bakeries) and as related products in supermarkets.

Since 2010, there has been a positive growth trend in the production of confectionery products in Russia, which are internal competition for bakeries, displacing them from store shelves.

The level of competition and foreign manufacturers

Domestic and foreign goods are represented on the Russian bakery market. The share of imports is no more than 22%. The main suppliers are Finland and Lithuania. In total, according to statistics, about 28 thousand enterprises are engaged in the production of bakery products on the territory of the state - for the most part these are representatives of medium and small businesses.

If we consider the structure of production, then the bulk of bakery products falls on factories:

The structure of the production of bakery products

The structure of the production of bakery products

About 75% of all traditional bread production is occupied by a “social” product. The regular segmentation of bakery products from large manufacturers is the ranking by category:

- Core of production (up to 80%) bread- the traditional assortment includes up to 25 positions;

- Minor production: baguettes and loaves - about 5 items;

- Additional production:

- non-traditional and borrowed varieties of bread, lavash, crispbread, etc. - up to 10 positions;

bakery products and pastries - about 25 items.

- non-traditional and borrowed varieties of bread, lavash, crispbread, etc. - up to 10 positions;

Despite the intense competition in the industry, the niche of bakery and fancy products remains unfilled, which appeared due to the redistribution of zones of influence between manufacturers:

- large factories are focused on the production of bread and do not pay due attention to the bakery assortment. They do not have a wide enough distribution network for rolls. This is due to high logistics costs and competition with supermarkets, which are more profitable to sell their own baked goods;

- bakeries in supermarkets, in turn, cannot compete in all consumer segments, and sell bakery products as secondary spontaneous purchases. Those. they do not allow the production of factories (in full), but also do not satisfy the demand with their volumes.

Due to this, the main competition in the production and sale of the bakery assortment takes place among private bakeries. The main tools for successful competition in such an environment are an understanding of the buyer's values and a competent sales system.

Consumer motives and values

According to the results of the analysis conducted by the Institute of Agricultural Marketing, the main selection criteria for the purchase of bakery products (in descending order):

- freshness;

- appearance;

- price;

- package;

- manufacturer.

The choice of the place of purchase of bakery products and muffins occurs according to the principle of one-time (all products in one place) or passing: proximity to the place of consumption - home, work, educational institution.

In cities with over 100 thousand people, there are already formats that have their own mini-bakeries. This has increased the influence of retailers on the market structure, since such private production of retailers withstands the basic requirements of freshness and low prices. But among the most successful formats for promoting bakery products, experts call regional grocery stores, discounters and supermarkets.