How to grow a wooden pallet business. Overview of the necessary equipment for making pallets

The good thing about owning your own business is that every future entrepreneur can find something of his own, based on criteria known only to him. For example, choose a business based on interests, size of financial investments, proximity to sources of raw materials.

In cities where many enterprises are located, for example, it is good to open a pallet manufacturing business or. A company producing containers will never remain idle. Even if production in a country is in its infancy, there is still always something to be scattered, poured, or transported. But we will now try to find out how profitable it is to make wooden pallets.

Idea analysis

Analyzing the need for the chosen business is the first step to its successful opening.

The production of pallets can definitely be considered profitable because:

- Such production has a wide range of clients interested in the product;

- Our country is very rich in forests. The main raw material for the manufacture of pallets is wood, and therefore, you do not have to spend exorbitant capital on the material;

- The production process does not require highly skilled labor, so wages will not be very high;

- Businesses using this product prefer to buy it locally rather than import it. Pallets from abroad are more expensive, they are inconvenient to transport, and why?

- The product described often needs updating, and its relevance does not in any way correlate with the seasons or weather.

Every novice businessman should not only estimate the profitability of the business, but also make a review of prospective buyers, at least in his city.

The company's target audience will consist of:

- Large companies involved in production;

- Large and not so big markets;

- Warehouses;

- Farms;

- Shops and supermarkets;

- Companies operating in the field of cargo transportation.

When negotiating with them, remember: competitors are not asleep. Offer the best conditions - and the production of wooden pallets as a business will go like clockwork.

Production technology

Pallets can be both typical and non-standard, but they all have approximately the same structure:

- Bottom boards;

- Wooden cubes connecting the top and bottom;

- Cross boards and flooring on top of them - this is where the load is placed;

- The structure of the pallet is specially designed so that it is convenient for a special machine to grab it.

The production of things like pallets refers to certain standards. One of the main ones is GOST-9557-87.

Materials for production are usually purchased. They can be done on site if you master the technology. Such materials should be stored in dry rooms in ventilated packages. The basic requirements and production technologies are described in GOST, where you can also find the sizes of boards and nails.

Pallets are produced in several ways:

- The first is the use of waste from the timber processing industry. It is the most affordable and widely distributed in sawmills. The pallets are constructed by hand using hammers and manual labor. It's cheap, but the products are of very low quality.

- The second method involves using a pneumatic hammer. The process goes much faster, but the output product is still of the same poor quality.

- The third method is used in small companies and is a semi-automated line.

- The fourth method is a fully automatic system. It is much more expensive, but the products are produced in large quantities and of good quality.

Business plan

A business plan for the production of pallets usually begins with the search for premises. I’ll say right away: you need a large room. Ideally, a warehouse or hangar so that a production line, a materials warehouse and a finished products department can be freely located there. There are special requirements for the building: it must be dry, well ventilated, there must be convenient access routes, and all communications must be connected. Sun, wind, dampness - all these factors can damage the appearance of the product or affect the strength, and therefore reduce the price of the product.Repair and equipment

Did you manage to find and rent a small warehouse? Great, now we need to get it in order. No repairs are required as such, but the walls need to be insulated and a ventilation system installed.

This production is a fully automated process and you need to buy equipment.

Equipment for the production of pallets

- A hydraulic nailer (there is an option to use one or two) is the main equipment.

The remaining vehicles are considered additional:

- Apparatus for cutting corners;

- Milling machine;

- Hydraulic conveyor.

Also don’t forget about shelves, a table and chairs, an equipped bathroom and a rest room for employees.

If you also make the material (boards) on site, you will need to purchase a sawmill, an edging machine (for cutting the edges of the boards) and an end-cutting machine for cutting the cubes connecting the two halves of the pallet.

The main thing you should pay attention to is do not buy new equipment. Sure, you can shell out for a production line that has never been used, but why spend several million more? If you buy machines manufactured in the 90s of the last century, they will function no worse than devices produced 5–10 years later.

The materials you will need to purchase are boards, cut according to GOST, or sawdust, nails. Regular nails will not work. Nails for pallets are called ruffs and are a cross between a nail and a self-tapping screw. They are thick and have special notches to ensure the nail fits firmly into the wood.

Equipment for the production of wooden pallets

Staff

To work, you will need to hire people to service the production line, an accountant, a manager whose responsibilities will include communicating with clients, a security guard and a cleaner.

You will need from 2 to 4 employees per line. There are no special requirements for their work experience or professionalism, so you can limit yourself to a salary of 150–200 dollars. You don’t have to hire an accountant on a permanent basis and limit yourself to his services in preparing reports. The manager will keep records of clients, work with Internet resources, answer questions and calls.

Advertising

Advertising for the production of pallets is, first of all, an offer of your services to the target audience that you identified in the “Analysis” paragraph. The person responsible for advertising should contact representatives of these companies and offer them mutually beneficial cooperation. TV, Internet and leaflets are almost useless in this case. The only thing that will work is an advertisement in a specialized press.

Pallet manufacturing as a business is not very suitable for a novice businessman. It is undesirable to open small, semi-handicraft enterprises here; expensive equipment is required. The production line alone will cost a business owner approximately $80,000. In the same time

In this material:

The profitability of pallet manufacturing as a business today is very high. You should start such a business activity with wooden pallets.

Business project concept

The entrepreneur organizes the search for raw materials, the production of pallets, and the sale of finished wooden containers. Pallets are flat-shaped trolleys with side sides and a hard bottom, made from various materials. Cargoes are placed on pallets. During loading and unloading operations, they are fastened together. For this purpose, heat-shrinkable materials, stretch films, belts, and fastening tapes are used. When moving goods, using a pallet can significantly save labor costs and time.

Often human muscle power is sufficient for the job, but it is impossible to achieve such speed and efficiency when manually placing individual loads. Such pallets of the same dimensions and shape can be easily moved by warehouse floor transport. For this purpose, hydraulic warehouse carts and forklifts are used. Such euro containers are used in sales areas, warehouses, and industrial workshops when moving goods by road, sea or rail. For warehouse storage, pallets with cargo are placed on pallet racks.

Advantages of this business:

- the organization of such a technological process does not require significant start-up capital;

- highly qualified labor is not required;

- the technology for producing pallets is extremely simple;

- no problems with sales;

- Euro packaging is in great demand among consumers.

First steps in the cargo pallet business

The main condition for the successful opening of pallet production is an analysis of the need for this product by consumers and the activities of competitors in this market segment. For a successful business, drawing up a competent business plan will be required before starting production activities. This document reflects an analysis of profitability and prospects for the development of the entrepreneur’s activities. Official status is necessary for your company to enter into long-term contracts.

The main condition for the successful opening of pallet production is an analysis of the need for this product by consumers and the activities of competitors in this market segment. For a successful business, drawing up a competent business plan will be required before starting production activities. This document reflects an analysis of profitability and prospects for the development of the entrepreneur’s activities. Official status is necessary for your company to enter into long-term contracts.

Using waste materials, it is possible to create cargo pallets manually in sawmills. This gives the entrepreneur the opportunity to start a business virtually without serious start-up capital. In your own garage, you can start small-scale production of flat stands if you have the required amount of cheap raw materials. To begin with, you can purchase inexpensive boards and edged material at any sawmill.

With the development of the business of creating and selling wooden packaging, production volumes are significantly increasing. This makes it possible to move to the next level. Purchasing equipment is an important issue. You can buy used lines, machines in good condition or new ones. GOST 9557-87 contains all the requirements for lumber.

For the manufacture of pallets, it is necessary to purchase raw materials brought to the required state. These are unedged boards, semi-edged boards of the 2nd and 3rd grades or solid bars. It is enough to purchase pneumatic hammers and 2 sawmills to open a full-fledged production.

Potential pallet consumers:

- companies involved in cargo transportation;

- a set of trading enterprises;

- agro-industrial complexes;

- transport and logistics companies;

- manufacturing enterprises.

All suppliers need to be carefully studied to find out what customers are happy with and what they are not happy with.

Calculation of business profitability

The average price of lumber is 1.5 thousand rubles. for 1 m³. Sawing a trunk into boards is most often done using a multi-saw machine RM-50, which costs from 500 thousand rubles. Taking into account the price of building materials, employee wages, taxes, rent of premises and other expenses, the cost of 1 pallet is 125 rubles. The income from each transport container will be about 75 rubles, since its price is approximately 200 rubles.

Features of pallet production

The production technology does not require special knowledge. Using a pneumatic hammer, a full-fledged wooden pallet can be made in a few minutes. To assemble wooden pallets from prepared parts, the PalletsLine machine is used. The cost of this professional conductor is from 260 thousand rubles. Its productivity per shift is 550 pcs.

Automated lines should be preferred to produce high-quality pallets. Products must be manufactured in accordance with GOST requirements. All pallets must be the same size to make optimal use of transport space. In the modern world, different pallet standards are used. Compliance with European transport packaging standards is carefully monitored by specialists, taking into account the relevant regulatory documents.

Automated lines should be preferred to produce high-quality pallets. Products must be manufactured in accordance with GOST requirements. All pallets must be the same size to make optimal use of transport space. In the modern world, different pallet standards are used. Compliance with European transport packaging standards is carefully monitored by specialists, taking into account the relevant regulatory documents.

Euro pallets with a size of 1200x800 mm are fully suitable for any type of freight warehouse transport. It is optimal for international cargo transportation. The use of such euro containers makes it possible to group boxes of goods using mechanical means, ship a lot of goods, and transport them.

Company personnel

At least 500 units per day are required to be produced to maintain good turnover, so sufficient labor is required. It is impossible to make several hundred pallets per day with 1 or 2 workers. Your company must have at least 5 auxiliary workers and 3-4 foremen on staff. If production is located close to wood sources, transportation costs will be significantly reduced.

The production of pallets, if properly organized, is a very promising business option.

The client will find you himself, subject to reasonable prices and high quality.

Order a business plan

| Investments: Investments 50,000 - 500,000 ₽ The history of the company begins in 2016, in the city of Penza. Initially, the main direction of the company was the development of commercial projects with augmented reality. After a number of successfully completed large projects, the decision was made to develop and produce our own augmented reality products. Initially, New Year's products with augmented reality were developed for wholesale sale, and as a result, at the end of the year there were excellent... |

| Investments: Investments 450,000 - 1,000,000 ₽ Samogonka.NET company is a network of retail stores selling folk goods: moonshine stills, goods for winemaking, brewing, cooperage products, samovars, and related thematic products. We are a dynamically developing trading and manufacturing company. We have been on the market since 2014. Currently, the company has a group of federal online stores: Samogonka.NET / SeverKedr, including a wholesale and franchising department. In our stores... |

| Investments: Investments 370,000 - 1,000,000 ₽ Pyrolysis boilers Tundra - An alternative to gas! You will be a manufacturer and not a middleman. Our pyrolysis boilers replace gas. This is the most profitable way to heat a room after mains gas. 1st place in cheapness is occupied by main gas (0.5 kopecks per kW) 2nd place pyrolysis boilers (0.8 kopecks per kW) 3rd place waste oil (1.83 kopecks per kW) 4... |

| Investments: Investments 1,400,000 - 1,800,000 ₽ The Crown® brand was founded in 1986 in Canada. At the moment, more than 1000 integrated corrosion protection stations are successfully operating in the world. The unique product T40, which was specially developed by the company's engineers, allows comprehensive protection of vehicles from the harmful effects of the environment. The composition of the inhibitor is protected by a patent, production is organized only at the Krown® company plant in Canada. Every year more than 1,000,000 transport... |

| Investments: Investments 550,000 - 2,000,000 ₽ Open your own chemical production with NPK AtomHim! You will be able to produce products in your region: auto chemicals and auto cosmetics, antifreeze, antifreeze and antifreeze, household chemicals, professional liquid soap. chemistry for enterprises. You can sell it, offer the best price than dealers for similar products. The research and production company "AtomHim" has been working in the field of chemical production for more than 6 years.… |

| Investments: Investments 1,500,000 - 4,000,000 ₽ The company "KULT STROY" is No. 1 in the design and construction of "Inverted Houses" in Russia, having a slope in two planes of 10 and 13 degrees. At the moment, we have developed and implemented projects in the following cities: Rostov-on-Don, Krasnodar, Stavropol, Yaroslavl, Penza, Gelendzhik, Perm, Ulyanovsk, Voronezh, Blagoveshchensk, Evpatoria. Our long-term plan is for every city on Earth with a population... |

| Investments: Investments 4,000,000 - 8,000,000 ₽ INGLOT is a wide network of branded salons of European professional decorative cosmetics and skin care products. Our brand independently creates cosmetic products, accessories and equipment, currently uniting more than 700 retail outlets around the world. The mission of our company is to produce high quality cosmetics at an affordable price for everyone. These are products you can trust... |

| Investments: Investments 400,000 - 2,000,000 ₽ NIKI FILINI has been working since 2013, we specialize in selling youth clothing. We focus on selling sweatshirts, t-shirts, hats, accessories and many other products. We already have 31 franchisee partners working with us. Franchisee partners grow and help each other. Our goal this year is to open more than 69 stores through the franchise system. We… |

| Investments: Investments 1,000,000 - 2,000,000 ₽ In 2016, the company carried out a full launch of automated production of the First Furniture Factory-ALNO joint venture, rebranding of the factory, a new model range for various segments and the premium kitchen brand Bruno Piatti. A joint venture with the Piatti Factory made it possible to produce kitchens according to Swiss quality standards. Today, the First Furniture-ALNO is: -52,000 m2 of production and warehouse space. -Capacity – 50,000 sets of furniture... |

| Investment: Investment 75,000 ₽ We have been producing unique "Norwegian houses" for 5 years. We invite you to open the production of “Norwegian Houses” in your region and earn 2.5 million rubles. in year! The uniqueness of "Norwegian Houses": A residential 2-storey house for permanent residence, with an area of 33 sq.m., is installed in 1 day and costs only 590,000 rubles! The house is manufactured in a factory, ready to be transported and installed... |

| Investments: Investments 10,000,000 - 15,000,000 ₽ The history of the company began in 1948 and goes back 70 years. Currently, ROBERTO BRAVO is an international company with offices in Vicenza, Istanbul and Moscow, and modern production facilities in Italy, Turkey and Korea. ROBERTO BRAVO is a regular participant in authoritative industry exhibitions that are trendsetters in world jewelry fashion: VICENZAORO Italy, JEWELRY SHOW Turkey, International Jewelery Show… |

| Investments: Investments 1,800,000 - 4,320,000 ₽ The COZY HOME retail chain of stores is a corner of comfort in a modern dynamic city. The store's assortment includes exclusive collections of bed linen, fashionable home clothes, original decor, high-quality terry products, pillows, blankets and various cute things for your home. The emphasis is primarily on textiles, because the Company has long been a leading expert in this field and has… |

The growth in construction volumes causes demand not only for building materials, wood products, etc., but the need for packaging and containers is also growing. One of the most common types of “packaging” used when transporting various objects, as well as in construction, are wooden pallets. Therefore, in this article we will look at some issues related to compilation.

The production of packaging products is sometimes more profitable than the production of the goods directly for which this packaging is produced. But as in any business, a number of questions may arise when organizing a pallet production enterprise. It is important to provide for them at the planning stage.

Key features of a pallet production business plan

Pallet production planning

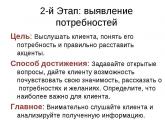

When deciding to launch a new business, you should carefully analyze all aspects of the matter. Analysis of the market situation, identification of the “pain” (problem that requires solution) of the consumer, development of your own strategy - all these are necessary steps when drawing up business plan For pallet manufacturing companies.

Moreover, project planning will show the prospects for creating an enterprise, and will also help develop a business development strategy. It is important to support all conclusions drawn with reliable calculations.

Description

Files

Activities of a pallet manufacturing company

The main goal of organizing such an enterprise is the production of wooden pallets (pallets), which have a wide range of applications. Wooden pallets are actively used as “packaging” when transporting equipment and other goods. Recently, the trend has become the production of furniture and various interior elements from pallets.

Simplified, the activities of the enterprise look like this:

- Purchase of raw materials (boards or untreated wood);

- Receipt of finished pallets and their further sale.

The attractiveness of such production lies in the fact that the products are manufactured from only one type of raw material, which does not require complex processing.

IN business plan for pallet production It is also necessary to highlight issues related to the sale of products. It is better to sell products directly from the enterprise - that is, through retail sales. Although it is also possible to conclude supply contracts with construction markets and supermarkets. It all depends on the specifics of the sales markets and the characteristics of the products produced.

1 – Summary

1.1. The essence of the project

1.2. Amount of investment to launch pallet production

1.3. Results of work

2 – Concept

2.1. Project concept

2.2. Description/Properties/Characteristics

2.3. Goals for 5 years

3 – Market

3.1. Market size

3.2. Market dynamics

4 – Staff

4.1. Staffing table

4.2. Processes

4.3. Wage

5 – Financial plan

5.1. Investment plan

5.2. Financing plan

5.3. Pallet production sales plan

5.4. Spending Plan

5.5. Tax payment plan

5.6. Reports

5.7. Investor income

6 – Analysis

6.1. Investment analysis

6.2. Finance Analysis

6.3. Risks of pallet production

7 – Conclusions

The business plan for the production of pallets is provided in MS Word format - it already contains all the tables, graphs, diagrams and descriptions. You can use them "as is" because it is already ready to use. Or you can adjust any section to suit you.

For example: if you need to change the name of the project or the region where the business is located, this can be easily done in the “Project Concept” section

Financial calculations are provided in MS Excel format - the parameters are highlighted in the financial model - this means that you can change any parameter, and the model will automatically calculate everything: it will build all the tables, graphs and diagrams.

For example: if you need to increase your sales plan, then just change the sales volume for a given product (service) - the model will recalculate everything automatically, and immediately all the tables and diagrams will be ready: monthly sales plan, sales structure, sales dynamics - all this will be ready .

A special feature of the financial model is that all formulas, parameters and variables are available for change, which means that any specialist who knows how to work in MS Excel can adjust the model to suit themselves.

Rates

Reviews from our clients

Feedback on the business plan for the production of paving slabs

The purpose of planning was, on the one hand, to attract funding, and on the other hand, we also wanted to have a clear picture of how we would develop. In the end, I liked the plan. In the business plan for a workshop for the production of paving slabs, I liked the financial model, I liked that it was easy to use, easy to adjust to your needs, and there were no questions about it in the bank either. At the moment, a loan of 19 million has been received. rubles Thank you! This result was obtained, including with your help. Good luck!

Maksimov K.O., Nizhny Novgorod,

Feedback on the business plan for developing a sand quarry for sand extraction

To expand production, we needed to attract investors. More precisely, we had “our own” investor, but in order to work with him we needed a business plan. Representatives of the company site provided us with invaluable assistance in drawing up this document, as a result of which the investor was satisfied with the quality of the business plan. We received investments worth 40 million rubles for the purchase of new equipment.

Egor Valerievich, Kostroma, General Director

Feedback on a business plan for a concrete plant

We were satisfied with the business plan for the concrete plant. All formulas are easy to use and very simple, all explanations are clear, and any changes can be made to the finished model. In fact, this is the first business plan that has proven to be easy to use and clear to understand.

M. L. Ivanova, Financial Director, World of Construction JSC

Drawing up a business plan for the production of pallets

Paving slab market analysis

In general, the situation in recent years has been favorable enough to open a business producing wooden pallets. In addition, consumers of such products can be a variety of organizations and trading companies.

Until recently, the main competitors were foreign pallet manufacturers. However, domestic enterprises can compete with foreign ones due to lower prices (saving on import duties and delivery). At the same time, the production technology does not require high-tech equipment, which allows us to produce products at the quality level of foreign analogues.

At the same time, one should not forget about the analysis of regional competitors and consumers. Although the market capacity is quite large and, most likely, the product will find its consumer, it is better to carefully evaluate everything at the planning stage.

You can expand production volumes and increase the sales market if you launch an additional related line for the production of sawdust pellets. will help you understand all the nuances of this matter.

Registration of production

When creating an enterprise for the production of pallets, it is necessary to register it. To do this, you can register as an individual entrepreneur or as a limited liability company. At the planning stage, keep in mind that you will have to spend time providing all the documents - to the tax office; to the Pension Fund and the Social Insurance Fund, open bank accounts, obtain other permits - conclusions from the labor protection inspection, fire safety, etc.

Production facilities and equipment

At one of the first stages, you need to decide on the location of the company, select the necessary equipment, and, in accordance with the dimensions of which, determine the size of the production and utility areas.

To save money, production premises can be located outside the city or in an industrial zone, where the rental cost is several times lower. Since raw materials and finished products are quite large, care will have to be taken to ensure sufficient space to accommodate:

- Manufacturing facility;

- Raw materials warehouse;

- Finished goods warehouse;

- Administrative premises;

- Utility rooms.

IN production business plan pallets You also need to specify the characteristics of the equipment used. The main equipment will be a production line with nailing machine. Additional equipment that may be useful:

- Hydraulic conveyor;

- Corner framing machine;

- Milling machine.

The final list of equipment, as well as the main categories of personnel, will depend on the production program and staffing schedule of a particular enterprise. At the initial stage, the following specialists will be sufficient:

- Manager;

- Production line operator;

- Handymen

- Loaders;

- Security guard;

- Other auxiliary workers.

Investment calculations in a business plan for the production of pallets

Basic calculations depend on technological solutions and the production program of a particular enterprise, so it is usually difficult to identify a unified structure and provide specific figures for the required investments. But you can download a sample on our website pallet production business plan, the financial model of which will allow you to automatically calculate all the necessary indicators depending on the characteristics of your project.

- Equipment - xxx r.

- Premises (rent) - xxx rub.

- Purchase of raw materials - xxx rub.

- Working capital - xxx rub.

- Marketing - xxx r.

- Unforeseen expenses (10%) - xxx rub.

ABOUT It is quite difficult to name the total amount of investment, since the final figures depend on many factors. But usually, launching a serious enterprise requires considerable funds - approximately50 - 150 million rubles.

Operating costs for pallet production

In addition to investment expenses in any business, there are also operating expenses associated, as a rule, with the purchase of raw materials and the payment of wages. Their approximate structure for a pallet manufacturing company is as follows:

- Rent – xxx rub.

- Salary – xxx rub.

- Raw materials – xxx r.

- Utility payments – xxx rub.

- Depreciation – xxx rub.

- Taxes – xxx r.

- Other expenses (10%) – xxx rub.

- Total operating expenses for the month - xxx rub.

Total expenses will consist of investment and operating expenses.

Project income

Income items will also depend on a number of factors. Among them are the elasticity of demand, competitors' strategies, market capacity, production scale, and assortment.

In the case of pallet production, income can be generated mainly through the sale of standard pallets in accordance with domestic GOSTs. Further, with the expansion of the production program, it is possible to generate income from the sale of the following types of products:

- Euro pallets;

- Euro pallets;

- Cargo pallets.

Sales of products are possible through various distribution channels - retail sales from a warehouse, concluding contracts with construction markets or companies.

The planned revenue from the production of pallets for the xxx period will be xxx thousand rubles. This value is calculated based on average prices in Russia per unit of product, which for the period xxx amounted to xxx rubles.

The average payback period for such production will be approximately 3 - 5 years.

The business plan has a clear structure, contains detailed financial calculations, and the financial model allows you to flexibly change any business parameter. This is the optimal solution for those who plan to attract investments, want to get a loan or have a ready-made template for developing their business plan.

Why do you need professional development of a business plan for a company that produces pallets?

Launching even a production that does not require special technology is always a risky and responsible undertaking. Before proceeding with the registration of an enterprise, it is necessary to plan and calculate everything. Correctly drawing up a business plan will save you time and money, as well as attract investment and credit resources. For example, on our website you can download a sample of the finished business plan for the production of pallets. This business plan presents a clear structure of all necessary sections and a financial model that allows you to automatically calculate all investment indicators. In addition, with the help of a professionally developed business plan, it is easier to convey the idea of the project to the investor and convince him of the advisability of investing in your business. You can also order the development of an individual turnkey business plan, taking into account the specifics of your business, by clicking on the link below.

Thus, the production of pallets is a profitable, relatively new endeavor that does not require complex technologies. But the success of the activity will depend on a reliable market analysis and a competent enterprise strategy.

Producing packaging is a very simple matter. In addition, organizing the entire technological process will not require serious investments from the entrepreneur. That is why a novice businessman should pay attention to the production of pallets, or pallets. This is a flat-shaped transport container made of metal, plastic or wood. It is intended for storage, as well as for moving cargo using mechanical means.

The production of pallets is very important. This is due to the demand for these products in the market, where, due to their high cost, there are no imported analogues. In addition, it attracts novice entrepreneurs and the relatively small capital that will be needed to purchase equipment for the production of pallets.

The target audience

The production of pallets as a business is a very promising option. This product will certainly be of interest to those organizations that use warehouse space in the course of their business activities. Among potential clients, several main groups can be distinguished:

- manufacturing enterprises;

- shopping centers and supermarkets;

- logistics companies;

- agro-industrial enterprises.

Planning

At the first stage of implementing your idea, you will need to draw up a business plan, which will detail the production of pallets from scratch. This document should take into account the main features of the production of these products. Domestic companies producing pallets, adhering to the recommendations of GOST 9557-87, produce “European pallets”. These products comply with all existing European standards and are very competitive in the market.

At the planning stage, you will need to determine how the technological process will be established. In order to produce high-quality pallets, it is worth giving preference to automated lines that will allow the production of products in accordance with GOST requirements.

When planning your future business, you will also need to find out the main distribution channels, while securing agreements with enterprises. An important step before starting your own business is to study potential competitors. Only after this will it be possible to make an offer to your clients that will be the most profitable for them.

Registration

To draw up and sign long-term contracts for the wholesale supply of products, your company must have official status. In this case, it is impossible to do without registering an individual entrepreneur, OJSC or LLC. This should also be taken into account when drawing up a business plan.

Purchase of equipment

Pallet production as a business must begin with the purchase of a machine or line. They can be either new or used. Moreover, you should not immediately abandon the second option. Used pallet making equipment can be in decent condition and provide good returns for a small investment.

Today there are many offers on the market for entrepreneurs starting their own business. The price of lines and machines on which wooden pallets will be produced differs depending on the year of their manufacture and terms of use. Some proposals even date back to 1980. However, if the machine has undergone all major repairs on time and is currently in good condition, then it is advisable to purchase it as equipment for the production of pallets. The price of equipment produced in subsequent decades is much higher, which is unprofitable in the early stages of business development.

An entrepreneur must also decide on the scope of his business. The prioritization will depend on this, which will allow you to select the type of equipment needed.

Technological process

The production of pallets is not particularly difficult. To produce this product you will need premises, tools, equipment and raw materials. The main stages of the technological process itself include:

- sawing blanks into boards and into bosses;

- cutting boards;

- trimming of bosses;

- direct assembly of the product.

These simple jobs can be done by any employee who has basic skills in using a circular saw, drill and screwdriver. The assembled pallets are not further processed - they are not primed or painted. it is simply stored awaiting sale.

Raw materials used

To produce pallets, you will need wood whose moisture content does not exceed 18-20%. Raw wood will be cheaper. It will also be possible to make blanks from it, and then assemble pallets. Just keep in mind that with this option, drying will be required for the finished product. And for this you will need a special room and additional funds for heating it.

That is why it is most profitable to purchase raw materials that have already been brought to the required state. In order to somewhat reduce the cost of wood, it makes sense to enter into contracts with the lumber manufacturers themselves, bypassing the services of intermediaries. This will ensure a profitable purchase of raw materials of good quality. Placing a pallet production facility in close proximity to wood sources will help reduce transportation costs.

The raw materials for the manufacture of pallets are considered to be boards of the second and third grades or bars. Checkers consisting of glued sawdust are also suitable. Boards can be used both semi-edged and unedged. The bars for pallets are taken in one piece, but their cost is twice that of the version made from glued sawdust. All currently existing requirements for lumber are contained in GOST 9557-87.

Nails are also necessary for the production of pallets. They hold all the prepared parts together.

If the production of pallets is established in small quantities, then the products can be produced manually without renting a special room, as well as purchasing equipment. However, with established sales in decent volumes, you will need to set up a workshop.

Manual assembly of pallets

Such a pallet will require the purchase of a special table. It is equipped with length and width limiters that allow you to set the required one. Before starting work, the table is installed horizontally. Cones are laid out in its special grooves, and on them are boards for the bottom and top. Then one or two workers fasten the workpiece with nails on both sides. To do this, use a regular or pneumatic hammer.

Often in sawmills, pallets are knocked down manually without tables, using production waste. Of course, this option requires low costs, but it is impossible to produce a competitive product. The pallets will be cheap, but of poor quality and in scanty quantities.

A special table allows you to significantly speed up the technological process. It will not take up much space, but at the same time it will allow you to control the parameters of the product and the correctness of its angles. In addition, the employee is exempt from operations such as measuring and checking squareness. This allows you to produce up to two hundred products in one shift.

Semi-automatic line

Using more productive equipment, you can significantly increase the number of products produced. For this purpose, a semi-automatic line for the production of pallets can be purchased.

It produces one and a half pallets within one minute and is serviced by two operators. One driver is also required for its operation. Such equipment will require a special room, since its length is 6 meters, width - 2 meters, and height - 3 meters. The minimum cost of a semi-automatic line is within five million rubles. Such equipment, manufactured in Europe, is capable of producing large volumes of finished products. In addition, it can survive for quite a long time without major repairs. However, the main obstacle to purchasing such a line may be its price, which starts at ten million rubles.

Automatic equipment

If you have an impressive amount of start-up capital (up to 10 million rubles), you can think about purchasing the most productive line. Automatic machines are capable of producing up to 650 pallets within one minute. The products produced in this way are of high quality. Automatic lines assembled in Europe will be able to operate without maintenance for ten years. To service them, five to six operators and two to three forklift drivers will be required.

Profitability of production

The profitability of a pallet manufacturing business will directly depend on the cost of raw materials and the volume of products produced. The more pallets produced during one shift, the faster the financial investment will pay off.

When properly organized, this business is one of the most profitable. Its payback period is on average two to three years, because pallets are in constant demand, and their production takes little time and labor.

Plastic pallets

Recently, the production of plastic pallets has been gaining momentum. This is due to the new conditions that dictate current interstate economic relations. Plastic pallets are especially popular among both manufacturers and carriers, as they increase the safety of transporting cargo over long distances.

It is, of course, impossible to produce such a product manually. A novice entrepreneur will have to purchase special equipment, having previously decided how this product will be produced.

Plastic pallets can be produced using the injection molding method. The product is obtained after pressing special raw materials into molds with high pressure.

Another method for producing plastic pallets is rotary. In this case, the plastic powder hardens in a mold rotating in an oven. There is another way - injection molding.

It is worth saying that the reliability of plastic pallets depends on the method of their manufacture. The equipment used also plays a significant role in this.

Recently they have become very popular (made in Russia). Made to order using special equipment, they can have various shapes.

That is why you can consider the production of shower trays as a business idea. Today, these products, made of acrylic, are very popular in the consumer market. Such pallets are optimal according to many criteria, which is why they have won favorable reviews from customers. Acrylic products are low cost, easy to install and convenient to use. The varied design of such products also attracts buyers. Given the high consumer demand, you can count on high profitability of the business, which will soon begin to generate significant income.

The pallet production business is a highly profitable endeavor. Since not a single large warehouse, wholesale center or retail trade can do without this type of product.

Market analysis

Today, the production of wooden pallets is considered one of the highly profitable types of business. After all, large manufacturers use them for transporting and storing goods, and small retail outlets place their products on wooden pallets.

However, production revenue, as with any other type of product, will directly depend on market demand. You can achieve the maximum percentage of sales only by establishing large-scale production.

Fortunately, the absence of foreign competitors and the low level of demand for plastic, metal and other types of products simplify the task.

Registration and organization of business

You can register a new type of business by contacting the branch of the Federal Tax Service at your place of residence. To do this you need:

- to write an application;

- provide the primary package of documents;

- pay the state fee.

The tax form must be indicated as personal income tax, the reporting period is once a quarter. Select code according to OKVED.

Premises and equipment

To launch a production line, a number of conditions will need to be met. This is necessary to obtain permits and optimize production. These include:

Some entrepreneurs choose to build a barn instead of renting a suitable space. The advantages of this solution include the ability to rent out empty space and receive money for it or rent out the premises completely if things don’t work out.

The disadvantages of this solution include the high cost of the object. That is, you first need to purchase a plot of land, then begin construction and renovation. This will cost at least 2,000,000 rubles. Which significantly increases the cost of the project.

The selection and installation of equipment in production depends on the type of work activity:

- Manual assembly. All you need is a hammer, nails, a saw and a measuring tape.

- Semi-automatic line. Implies the presence of at least one power tool and the average volume of deliveries under existing contracts.

- Automatic line. The most popular among entrepreneurs, it allows you to perform high-precision work while increasing production volumes.

Production technology

Theoretically, the production technology is the same for all manufacturing methods (manual, automatic, semi-automatic) and, nevertheless, in practice, each of them has its own characteristics.

Manual assembly. The basic manufacturing principle is to assemble wooden jigs (parts) without any involvement of machinery. All you need is:

- hammer;

- nails;

- hacksaw saw.

When busy up to 12 hours a day, you can produce 60 units of goods per day. This production method is “sham” and the demand for such products usually does not go beyond food markets and small repair shops.

Semi-automatic line. It is the same assembly of wooden conductors only using minimal electrical equipment:

- drills;

- screwdrivers;

- assembly machines.

In this case, the safety margin of the finished product will be increased, since harder types of wood can be processed using the equipment. The number of pellets produced by such a plant per day is about 150 pieces, provided that the working day is at least 12 hours.

Automated production. This option is the most suitable for many beginning entrepreneurs. The equipment for production is the simplest, inexpensive, and the operating speed is correspondingly higher.

Automatic, semi-automatic or manual assembly line?

The choice of a particular production line depends on the initial level of possible costs, the desired level of income and the personal efforts of the entrepreneur.

The choice of a particular production line depends on the initial level of possible costs, the desired level of income and the personal efforts of the entrepreneur.

Economists and financial analysts have long proven that tangible income from the production of any type of product can be obtained only by establishing full automation, while carrying out constant sales in large quantities. In any other case, you should only hope for an income level slightly above the average salary in the country. It is 30,000 rubles per month.

Raw materials and suppliers

You need to purchase raw materials for production (wood or finished conductors) only from Russian suppliers. The main sellers of such products are:

- woodworking enterprises;

- sawmills;

- forestry companies and other organizations trading in timber and timber.

In addition to the above method of obtaining raw materials, you can use an additional option - enter into an agreement with state environmental safety services and forest protection enterprises. In this case, the material will not cost a penny, and the level of income from the sale of pallets made of birch, pine, oak and larch will be noticeable.

It is worth noting that the second method of obtaining “conditionally free wood” is extremely complicated.

The Government of the Russian Federation issued a decree that trees that died due to natural causes cannot be used for personal purposes, much less exported, among them:

- fire;

- flooding;

- burnout.

However, every law has its own loophole and the ability to circumvent it. One of these methods is an agreement on forest cleansing, because not every felled tree can bring tangible benefits to the environment and its inhabitants.

Staff

All economic activities of the enterprise are based on a well-structured marketing plan and a team of employees whose personal contribution is simply invaluable. In order to get things going and become a successful businessman, you will need to include in your staffing schedule:

- Workers.

- Equipment adjuster (electromechanics).

- Accountant.

- Secretary.

- Delivery driver.

Sales market

The main buyers of wooden pallets are:

It is worth concluding mutually beneficial contracts with these enterprises. Most often, customers order large quantities of goods, which helps production develop and increase momentum.

However, in order for sales to bring not only “running” income, but also additional income, you need to purchase a car. Since initially there are few orders, a Gazelle, which can accommodate at least 100 units of goods, will be sufficient. Subsequently, it will be possible to buy another car or exchange the old one for a more serious type of transport.

Financial component of business

Absolutely any type of business is an independent or group project that requires full dedication and personal investment from the participants. In order to determine the liquidity of the entire process, it is necessary to calculate its economic component, which includes such items as:

- initial investment;

- income level;

- payback period.

Cost of opening and maintaining

Despite all the financial “ease” and relevance of this type of business, you still have to spend a substantial amount on registration and opening. Project cost items include:

The total amount payable depends on the chosen method of business activity and production line and can range from 20,000 rubles to 3,500,000 million rubles.

Profit per month

As mentioned earlier, economists and businessmen have long proven that the maximum level of income can be achieved by engaging in large-scale production. The profitability of such activities with medium or large monthly deliveries reaches 400,000 rubles, minus taxes and other payments.

However, this mark can only be achieved if the owner of the company is able to conclude several lucrative contracts in the first 2 months of work.

Payback period

The payback period for production directly depends on the demand for a product or service in the consumer market. The production of wooden pallets is currently a super popular type of business activity and pays off within 6-7 months from the start of work.

The problem of choosing a suitable business solution comes down to the same law: “you need to work for the future.” Unfortunately, when engaging in the most popular and even popular type of business, this is not always possible. Especially considering that the market segment has long been occupied by enterprising and forward-thinking manufacturers. Therefore, before registering an enterprise, you should think a few more times: “is this a business worth doing.”

Popular

- How to organize a business renting apartments?

- Washing machine repair business Without advertising is like without air

- Why sales growth can kill profits and the entire business

- Partnership to create an Internet business

- Where is the easiest place for an individual entrepreneur to open an account?

- Overview of the necessary equipment for making pallets

- Detailed review of the TextSale article exchange

- Earn money by viewing advertising Earn money by viewing commercial advertising

- All about the game Golden Mines

- Grouse breeding Grouse breeding at home as a business