Technology for the preparation of semi-smoked sausages. Equipment for the production of sausages Krakow sausage of the highest grade

The main raw materials for the manufacture of semi-smoked sausages are pork and beef obtained from adult animals. The pork content in most semi-smoked sausages is 40-100%. But some varieties of semi-smoked sausages are made from one beef meat (Minsk, beef, etc.). Semi-smoked sausages are also made from lamb meat, adding a small amount of beef and tail fat. Offal is added to some sausages (Semipalatinsk, special offal).

Semi-smoked sausages are made from cooled, chilled and frozen (defrosted) beef, pork and offal. Fresh meat is not used.

The best fat for semi-smoked sausages is pork belly or semi-hard bacon, which are less fusible and form a good pattern on the cut. Back fat and internal fat are not used for semi-smoked sausages.

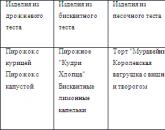

Table 5

Raw material preparation

Deboning and trimming

meat ambassador

Minced meat preparation

syringe

Draft loaves

Heat treatment

Storage

Implementation

Raw material preparation

When using frozen meat on the bones, it is pre-thawed in accordance with the technological instructions.

The incoming meat on the bones is inspected and, if necessary, cleaned and washed. Cleaning is done with a knife, removing dirt, bruises, veterinary inspection marks.

Washing is carried out for 30-40 minutes with water at a temperature of 35-40°C.

Deboning and trimming

Deboning and trimming is carried out on tables made of stainless steel or marble chips with removable wooden or plastic boards.

Chilled meat on the bones with a temperature in the thickness of the muscles (2 ± 2) ° C or defrosted with a temperature not lower than 0 C is sent to the boning.

Meat is deboned manually with a knife, leaving no cuts of pulp on the bones.

It is necessary to ensure that small bones do not get into the deboned meat, which impede the trimming of meat and its processing on machines. Deboning meat by hand is associated with the risk of cuts on the thumb and forefinger of the left hand, the abdomen and groin. To protect against them, protective chain mail nets such as an apron and gloves should be worn on two fingers of the left hand.

Table 6

The trimming of meat is produced in one grade, removing films, tendons, cartilage, lymph nodes, bruises, without disassembling into grades.

Complained single-grade beef should contain no more than 12% connective and adipose tissue. When trimming, fat or fatty beef is also separated in the amount of 22% with a fat content of not more than 35%. Single-grade veal contains 6% connective tissue.

There is relatively little connective tissue in pork, so the main separation of the veins should be carried out from the shank and thighs, separating the fat from the muscle tissue. Single-grade trimmed pork should contain adipose tissue from 30 to 55%. When trimming lamb, tendons and bruises are removed, if necessary, extracting raw fat and fat tail fat.

Single-grade mutton and goat meat should contain no more than 20% connective and adipose tissue.

In the process of trimming, the meat is cut into pieces weighing from 100 to 500 g, pork back fat and side fat are cut into strips about 15x30 cm in size.

Before grinding fatty meat, raw fat, bacon must be cooled to a temperature of 0 - 1C.

Frozen blocks of non-veined and non-sorted meat are subjected to defrosting. Meat blocks are released from packaging, weighed and placed on the racks of defrosting chambers. Blocks are defrosted at a temperature of 18-22°C until a temperature of at least 1-3°C is reached in the thickness of the block.

meat ambassador

When salting, trimmed meat is used, cut into pieces and chopped on a top with a lattice hole diameter of 2-5 mm.

To avoid the taste of salting, it is not recommended to grind trimmed pork for salting on a fine grate.

Veined pork for salting is crushed to 16-25 mm, adding 3 kg of salt and sodium nitrite 7.5 g for every 100 kg of raw materials in the form of a solution with a concentration of 2.5% and mixed in a meat mixer for 2-3 minutes. It is allowed to add sodium nitrite in the preparation of minced meat.

The salted raw materials are kept in various containers in the ripening chamber at a temperature of 0-4°C for 2 to 3 days.

Due to repeated contact with the surface of the hands of workers, tools and equipment during deboning, trimming and salting, microbial contamination of meat sharply increases. The sanitary and hygienic conditions under which these operations are carried out must be impeccable.

Sausage preparation

To prepare minced meat for semi-smoked sausages, raw materials, spices and other materials are weighed in accordance with the recipes of this technological instruction.

Minced semi-smoked sausages are prepared in a meat mixer or on a cutter mixer.

Figure 8 Figure 9

When using unsalted bacon or raw fat, salt is added at the rate of 3% to the weight of unsalted bacon.

Mixing of raw materials with spices and other components is carried out until a homogeneous minced meat and a uniform distribution of bacon or raw fat are obtained. The total mixing time for all types of sausages is 6-8 minutes. The mince temperature should not exceed 12°C.

The time from the end of the preparation of minced meat to the beginning of filling the shells should not exceed 6 hours.

Syringing minced meat

Vacuum syringes are used to inject minced meat into shells or molds. For these purposes, hydraulic or vacuum syringes are used. The technique of stuffing the casings with minced meat and the designation of product marks are similar to those for boiled-smoked sausages, however, the duration and temperature regime of the sediment are different and should be 2-4 hours at a temperature of 4-80C.

Figure 10

Draft loaves.

Draft is the process of keeping loaves, injected into the shell, in a suspended state.

In the process of precipitation, the minced meat is compacted and ripens, its color develops, and the shell is also dried. The draft of semi-smoked sausages is recommended to be carried out for 2-4 hours at a temperature of 8 0C.

Table 7. Heat treatment of sausages.

Smoking is understood as the effect on food products of volatile substances of smoke resulting from the incomplete combustion of wood.

In the process of salting, the structure of the muscle tissue changes, as a result of which it becomes more permeable to the substances contained in the smoke. Depending on the temperature at which the process is carried out, roasting, hot and cold smoking are distinguished.

Roasting is used in the production of semi-smoked sausages, which are smoked at 80 - 950 C for 6 - 12 hours (depending on the mass and thickness of the product) until 68 - 720 C is reached inside the product.

During the frying process, the components of the smoke can only penetrate into the shell and surface layers of minced meat. After hot smoking at 30-50 0 C for 2-48 hours, the products are boiled or smoked.

Sausages intended for shipment over long distances are additionally dried for 2-4 days at a temperature of 12-15 ° C.

The finished sausage should have a uniformly fried surface without slips, influxes of minced meat, an elastic texture and an even distribution of pieces of brisket, bacon and bold pork on the cut.

The moisture content of semi-smoked sausages ranges from 35-50%, and the yield of finished products is 65-80%.

Cooling of semi-smoked sausages.

After the sausage has undergone heat treatment, it is cooled and packaged.

Packaging, marking, transportation and storage

Semi-smoked sausages are packed in wooden reusable boxes in accordance with GOST 11354-82, plank - in accordance with GOST 13361-84, polymer reusable, aluminum or in containers made of other materials permitted for use by the Ministry of Health, as well as in specialized containers or container equipment.

Containers for sausages must be clean, dry, without mold and foreign smell. Reusable containers must have a lid. For local sale, it is allowed to cover the container with wrapping paper in accordance with GOST 8273, parchment.

It is allowed to pack sausages in repaired and sanitary-treated reusable wooden containers, which ensure the safety and quality of products.

The gross weight must not exceed 30 kg.

Half-smoked sausage of the same name is packed in each box or container.

Incomplete loaves of semi-smoked sausages weighing at least 300 g are allowed for local sale. At the same time, the cut ends of the loaf must be wrapped in a napkin made of cellophane in accordance with GOST 7730-74, parchment in accordance with GOST 1341-84 or other materials permitted for use by the Ministry of Health, and tied with twine . The number of non-whole loaves should not exceed 5% of the batch.

Transport marking - according to GOST 14192-77 with the application of the handling sign "Perishable cargo" and the tare weight. It is allowed not to apply transport marking on reusable containers with products intended for local sale.

Marking characterizing the products is applied to one of the end sides of the shipping container with indelible odorless paint using a stamp, stencil or sticking a label indicating: the name of the manufacturer, his subordination and trademark; names and varieties of sausages; manufacturing dates; gross weight, containers; designations of this standard.

Packages with packaged semi-smoked sausages of the same name, grade and date of manufacture are placed in corrugated cardboard boxes according to GOST 13513-80, reusable containers, specialized containers or container equipment. Net weight of packed sausages in boxes should not exceed 20 kg. Packaged semi-smoked sausages are allowed to be packed in polymer reusable boxes with a gross weight of not more than 30 kg, as well as in specialized containers and equipment containers with a net weight of not more than 250 kg. For each unit of transport packaging with packaged semi-smoked sausages, a label is glued and put inside indicating: the name of the manufacturer, its subordination and trademark; names and varieties of sausages; implementation period; designations of this standard.

In addition, each box, container or container-equipment includes a summary check indicating: net weight of sausage; the number and total cost of servings; date of manufacture.

In the absence of a total check, the above designations are indicated on the label.

The sale of semi-smoked sausages by weight in a retail network should be carried out if there is information on the nutritional and energy value per 100 g of the product (protein, fat, calorie content).

Semi-smoked sausages are transported by all means of transport in covered vehicles in accordance with the rules for the carriage of goods in force for this type of transport. In packaged form, they are transported according to the normative document for methods and means of packaging. Means of securing cargo in transport packages in accordance with GOST 21650-76, with the main parameters and dimensions in accordance with GOST 24597-81.

Half-smoked sausages are stored for up to 10 days in a suspended state at a temperature not higher than 12ºC and relative humidity of 75--78%.

In refrigerated rooms at a temperature not exceeding 6ºC and a relative air humidity of 75--78%, half-smoked sausages packed in boxes can be stored for no more than 15 days, and at temperatures from minus 7 to minus 9ºC up to 3 months.

In uncooled rooms at a temperature not exceeding 20ºC, semi-smoked sausages can be stored for up to 3 days.

Semi-smoked sausages packed under vacuum in a polymer film are stored at a temperature of 5 to 8º C for serving cuts for no more than 10 days, for portion cuts - no more than 12 days; at a temperature of 12 to 15º C with serving cuts no more than 6 days, with portion cuts - no more than 8 days.

Having studied the standard for semi-smoked sausages, we believe that the packaging of meat and meat products is an urgent problem in modern production and promotion of products on the market. The development of the Russian packaging market over the past ten years has had its own peculiarities.

Currently, in the structure of the Russian packaging market, polymeric materials account for 30%, cardboard and paper - 40-45%, metal containers - 10-12%, others - 13-20%. At the same time, the rate of increase in the production of polymer packaging is maintained. They reach annually from 7-12% and are ahead of other materials.

When using vacuum packaging, the rate of oxidative changes in muscle tissue pigments decreases. The color of the packaged semi-smoked sausage is preserved for 28-35 days at a degree of vacuumization of 95-98% and a storage temperature of 1-3ºC.

Packing portioned semi-smoked sausage in a gas environment with a high oxygen content (70-80%) and a relatively high concentration of carbon dioxide (20-30%) at a temperature of 2ºC increases its shelf life up to 15 days.

The shelf life of sausages packed in multilayer polymeric materials using MAP (Modified Atmospheric Environment) increases from 15 to 45 days.

As can be seen from the above data, packaging half-smoked sausage in gas-tight materials under vacuum and in a modified environment allows increasing its storage capacity.

half-smoked sausage minced cold supply

MINISTRY OF AGRICULTURE OF THE RUSSIAN FEDERATION

Federal Budgetary State Educational Institution of Higher Professional Education

Russian State Agrarian University - MSHA

named after K.A. Timiryazev

(FBGOU VPO RGAU - Moscow Agricultural Academy named after K.A. Timiryazev)

Abstract on the topic:

"Half-smoked sausages"

Completed by: student of group 403

Faculty of Technology

Burdyko N.P.

Checked by: Tsvetkova N.N.

Moscow 2013

Introduction 3

1. Characteristics of semi-smoked sausages 4

2. Features of production technology 6

3. Defects in sausages 10

4. Organoleptic quality assessment 14

Conclusion 15

References 16

Introduction

Semi-smoked sausages are one of the most popular types of sausages among buyers. Meat processing enterprises in Russia produce them in large volumes and in a fairly wide range. Due to the sharp rise in prices for meat raw materials, which led to an increase in the cost of semi-smoked sausages, their sales decreased significantly. In this regard, meat processing enterprises are faced with the problem of reducing the cost of semi-smoked sausages in order to make them again accessible to all segments of the population.

One of the ways to solve this problem is to use cheaper meat raw materials in the production of semi-smoked sausages, as well as various types of vegetable and animal proteins, food and flavor additives. Which led to a deterioration in the quality of sausages produced by the domestic industry.

In this regard, it became necessary to develop new recipes and technologies that allow the production of semi-smoked sausages at a relatively low cost from inexpensive block meat raw materials, meat with a high content of connective and adipose tissue, with PSE and DFD defects, meat after mechanical deboning, including poultry, as well as soy proteins or other proteins of plant and animal origin.

1. Characteristics of semi-smoked sausages

Semi-smoked sausages are sausages that, during the manufacturing process, after roasting and boiling, are subjected to additional hot smoking and drying.

According to GOST R 53588 semi-smoked sausages are classified:

Limit norms of mass muscle tissue in semi-smoked sausages:

High quality sausages can be made only with the appropriate selection of meat obtained from animals of a certain type, fatness and age. Beef meat is a binding material for minced meat. Pork gives sausages a delicate texture and a pleasant taste. Various types of sausages are not equivalent in their chemical composition and nutritional value. However, they are all products that contain relatively large amounts of protein and are rich in minerals.

The nutritional value of sausages is higher than the value of raw materials, because during the production of sausages, the least nutritionally valuable tissues are removed from raw materials. High nutritional value is also due to the high content of proteins in them, low-melting pork fat. The calorie content of smoked sausages is high, about 400 kcal, which makes them indispensable food products, especially for people engaged in physical labor.

2. Features of production technology

The production of semi-smoked sausages is carried out in two ways. Next, the first method for the production of semi-smoked sausages will be considered.

Semi-smoked sausage "Krakowska" is produced in accordance with GOST R 53588 "Semi-smoked sausages". In terms of safety indicators, semi-smoked sausage must comply with the requirements of SanPiN 2.3.2.1078 - 01 "Hygienic requirements for the safety and nutritional value of food products."

1 Acceptance and storage of raw materials. For the production of semi-smoked sausage, they take chilled, trimmed beef of the highest grade, trimmed semi-fat pork, with a mass fraction of muscle tissue of not more than 25%, spices and food additives, auxiliary raw materials.

The meat must be of good quality, from healthy animals and recognized by the veterinary and sanitary service as suitable for food purposes.

For salting, they use food table salt of the first grade, sugar - sand and sodium nitrite. To give a specific taste and smell, spices, garlic, flavors, smoke preparations are added.

Input control includes verification of accompanying documentation, visual control and organoleptic evaluation.

For meat raw materials, the presence of veterinary documentation, stamps and temperature are controlled.

For the manufacture of semi-smoked Krakowska sausage, chilled meat is used with a temperature in the thickness of the muscle tissue (1-2) 0C, meat storage temperature (0-1) 0C, storage temperature of auxiliary raw materials and spices (15-20) 0C.

Semi-smoked sausage "Krakowska" is produced in a casing, which gives it a shape, protects it from pollution, mechanical damage, microbial spoilage and excessive drying.

2 Preparation of raw materials. For meat includes cutting, deboning, trimming, sorting. The processes are carried out at air temperature (10-12) 0С, humidity 75%, temperature in the thickness of the muscles (2±2) 0С.

Dry ingredients are to be screened.

3 Ambassador. In the manufacture of semi-smoked sausage "Krakowska", the ambassador is carried out in a wet way. When salting, sodium nitrite is added in the amount of 7.5 g per 100 kg of raw material in the form of a solution with a concentration of not more than 2.5%, as well as a sugar solution.

4 Preparation of minced meat (cutting). Necessary for additional grinding of raw materials and mixing of prescription components. To obtain minced meat of the highest quality, follow the sequence of bookmarks. First, lean meat is introduced into the cutter, then part of the water, non-meat components and spices, fatty raw materials and the remaining water are added. The duration of the process is (8-10) minutes, minced meat temperature (6-8) 0С.

5 Molding (syringing). During the injection process, the quality and structure of the stuffing must be maintained. Half-smoked sausages are injected most densely. Minced semi-smoked sausages on hydraulic syringes are recommended to be injected at a pressure of 0.6 atm.

6 Draft. The duration of precipitation is (2-4) hours, at an air temperature of (4-8) 0C.

7 Heat treatment.

7.1 Roasting. The duration of roasting is (60-90) minutes, at a temperature of (90±10) 0С.

7.2 Cooking. Cooking duration is (40-80) minutes, temperature is (40-80) 0C, temperature in the center of the loaf is 72 0C.

7.3 Air cooling at 20°C for (2-3) hours.

7.4 Smoking. Semi-smoked sausages are hot smoked for (12-24) hours at a temperature of (43±7) 0C.

8 Drying. Semi-smoked sausages are dried at a temperature of (10-12) 0C and relative air humidity (76.5±1.5)% for (1-2) days until an elastic consistency is acquired.

9 Packaging and labeling. It is carried out using labels with information in accordance with GOST R 51074 - 2003 Food products. Information for the consumer. General requirements.

The marking must contain the following data:

1). name and location of the manufacturer (legal address, including the country, and if it does not match the legal address, the address of the production and organization in the Russian Federation authorized by the manufacturer to accept claims from the consumer on its territory (if any);

2). manufacturer's trademark (if any);

3). the name of the semi-finished product indicating the group, type, subspecies, category and thermal state;

4). net weight or quantity;

5). composition of the product;

6). nutritional value;

7). date of manufacture and packaging;

8). storage conditions;

9). best before date;

10). information on the presence of GMI;

eleven). designation of the standard or document in accordance with which the semi-finished product is manufactured;

12). conformity information.

10 Transportation and storage. Finished products are transported in refrigerated trucks in accordance with current regulations. Store at a temperature of (0-6) 0С, air humidity (75-78)%, no more than 10 days.

Send your good work in the knowledge base is simple. Use the form below

Students, graduate students, young scientists who use the knowledge base in their studies and work will be very grateful to you.

Posted on http://allbest.ru

Introduction

Chapter 1. Classification and technological processes for the production of semi-smoked sausages

1.1 Characteristics of the enterprise

1.2 Classification of semi-smoked sausages

1.3 Technological processes for the production of semi-smoked sausages

Chapter 2

2.1 Cooking minced meat

2.2 Molding

2.3 Heat treatment

2.4 Nutritional value and chemical composition

2.5 Evaluation of the quality of semi-smoked sausages

2.6 Packaging. Marking

2.7 Transport and storage

3. Calculation of raw materials

Conclusion

Bibliography

Applications

Introduction

Semi-smoked sausages - products made from minced meat enclosed in a shell, roasted, boiled, smoked and dried.

Meat processing enterprises in Russia produce them in large volumes and in a fairly wide range. Due to the sharp rise in prices for meat raw materials, which led to an increase in the cost of semi-smoked sausages, their sales decreased significantly. In this regard, meat processing enterprises are faced with the problem of reducing the cost of semi-smoked sausages in order to make them again accessible to all segments of the population.

One of the ways to solve this problem is to use cheaper meat raw materials in the production of semi-smoked sausages, as well as various types of vegetable and animal proteins, food and flavor additives. Which led to a deterioration in the quality of sausages produced by the domestic industry.

In this regard, it became necessary to develop new recipes and technologies that allow the production of semi-smoked sausages at a relatively low cost from inexpensive block meat raw materials, meat with a high content of connective and adipose tissue, with PSE and DFD defects, meat after mechanical deboning, including poultry, as well as soy proteins or other proteins of plant and animal origin.

Half-smoked sausages are the second most popular among the townspeople after boiled ones, and only a few pay attention to its composition and recipe.

The purpose of the work: to study the technology of production of semi-smoked sausages.

Relevance: this topic is of current importance, since at the present stage of development of the Russian market for sales and production of sausage products, quality requirements and other provisions (classification, assortment, examination, etc.) must be observed.

1. Consider the classification, range of products;

2. Analyze the requirements of GOSTs for the quality of semi-smoked sausages;

3. Consider raw materials for the production of semi-smoked sausages;

4. Analyze the technological scheme and processes for the production of semi-smoked sausages;

5. Describe the organization of control

6. Make an economic calculation

Chapter 1. Classification and technological processes for the production of semi-smoked sausages

1.1 Enterprise characteristics

The Talina Group of Companies traces its history back to 1988 with the restoration of the Atyashevsky Meat Processing Plant located in the Republic of Mordovia. In the early 2000s, a number of unprofitable agricultural enterprises joined it. sausage food half-smoked Dahurian

In 2002 MPK "Atyashevsky" manages the business of companies in the field of agriculture, meat processing and trade. All enterprises are equipped with modern equipment. The difference from many competitors lies in vertical integration. As part of the production process, each stage of food production is regulated: from growing grain to deep processing of meat, this allows you to quickly respond to changing market trends and increase business efficiency. The total number of employ employees exceeds 4,000 people.

Four meat processing plants of the holding, located in the Republic of Mordovia and the Trans-Baikal Territory, produce sausages and delicacies under the trademarks Atyashevo, Derevensky Dvorik, Ladnye da foldable, and Dauria.

More than 300 types of meat and sausage products are produced under the trademarks "Atyashevo" and "Dauria".

The high quality of products is confirmed by victories in various competitions of regional and federal significance. Talina has won more than 200 diplomas and medals, the agricultural holding is twice the winner of the Product of the Year and Company of the Year awards, the owner of the Grand Prix at the Prodexpo and WorldFood exhibitions.

The geography of sales is constantly expanding. Today, the holding's sausages and delicacies are sold in 47 regions of Russia, in such chains as Auchan, X5 Retail Group, METRO, Seventh Continent, O'Key, Lenta, Magnit. The holding is a regular supplier of chilled pork to McDonald's fast food chain.

Meat processing plant "Daursky" is the youngest in the composition of the meat processing enterprises of the agricultural holding. It was created by the complete modernization of the unfinished meat processing plant. In October 2009, it launched the production of sausages under the trademark "Dauria".

The capacity of the enterprise is 400 tons of products per month.

The sales volume of products of TM "Dauria" for 2015 increased by 47% compared to 2014.

The project started in 2009, when work began on the restoration of the meat processing plant, in the autumn of the same year, the first products left the assembly lines of the enterprise. In November 2011, the implementation of the 2nd phase of the project began - the primary processing of cattle, the facilities were put into operation in 2013.

Today, the plant can produce 1,500 tons of products per month, i.е. 18 thousand tons per year. Sausages and delicacies of the Dauria brand are made from cattle meat grown in the steppes of the Trans-Baikal Territory, and from pork from Talina farms located in the ecologically clean region of Russia - Mordovia. The range of finished products includes 60 items: ham, boiled, boiled-smoked, half-smoked sausages, sausages, sausages, delicacies, frozen semi-finished products. Products of TM "Dauria" are sold in the Amur, Irkutsk regions, Buryatia, Khabarovsk Territory, Trans-Baikal and Primorsky Territories.

In 2009, the youngest meat processing enterprise of the holding, MK Daursky (Zabaikalsky Krai, Krasnokamensk), launched the production of sausages and delicacies under the new brand name Dauria. These are products with traditional high quality for the holding. It is made from cattle meat grown in the steppes of the region. The combination of classic, time-tested recipes, advanced technologies, modern equipment, environmentally friendly raw materials and the qualifications of specialists allows us to obtain healthy and tasty products. TM "Dauria" offers a wide range of boiled, boiled-smoked and semi-smoked sausages, frankfurters, sausages, hams and delicacies.

The meat processing plant "Daursky" includes the following workshops:

Shop for slaughter and primary processing of livestock

Refrigeration shop

Shop for the preparation of sausages

tar-washing

Finished goods warehouse.

Shop for slaughter and primary processing of livestock: slaughter shop with a capacity of 20 heads of cattle per hour - a comprehensive, low-waste and efficient production. The slaughter line involves the subsequent processing of by-products, cooling, cutting into half carcasses, waste processing at treatment facilities. There is a waste processing plant that allows not to dispose of waste at special plants, but to process it on the spot and obtain demanded products (fat, meat and bone meal). This eliminates the negative impact on the environment.

The shop of slaughter and primary processing of livestock consists of:

Ante-slaughter base for livestock

Slaughter line

white organ department,

Department of red organs,

offal packaging department,

Foot Processing Department

Salting Department

Refrigeration shop includes:

freezing chambers: chamber No. 1 - for freezing after slaughter and storing meat on the bone; chamber No. 2 - for storage of intestinal raw materials;

chamber No. 3 - for cooling meat on the bone after slaughter

chamber No. 4 - cooling and storage of meat on the bone on a suspension, 0-4;

chamber No. 8 - raw meat storage;

chamber No. 12 - offal freezing chamber, -20;

chamber No. 13 - freezing and storage of block raw materials and by-products;

chamber No. 14-15 - storage of offal, block raw materials, headquarters -18-20; sanitary chamber.

Sausage preparation shop:

Spice warehouse, packing of spices

Warehouse of auxiliary materials

defrosting chamber

Raw material department

ripening chamber

Molding department

thermal department

Accumulator (in it sausages are cooled from 0 to + 4 ° C and delivered to the warehouse of finished products)

Finished goods warehouse:

- packing shop

Marking shop

1. 2 Classification of semi-smoked sausages

According to the type of meat, smoked sausages are divided into beef, pork, lamb, horse, from the meat of other species of animals and birds, as well as from a mixture of beef or other types of meat with pork and bacon;

According to the composition of raw materials - for meat, offal, blood;

By type of casing - sausages are prepared in natural casings, artificial casings and without casings;

According to the drawing of minced meat - minced meat can be with a homogeneous structure, with the inclusion of pieces of lard, tongue, pieces of coarsely chopped muscle and adipose tissue;

According to the purpose, sausages are divided into sausages for general consumption: dietary sausages, sausages for baby food. Various assortment groups of sausages include the following most common assortment names:

Semi-smoked sausages contain less moisture than boiled sausages, are better preserved, have a pleasant smell of smoked meats.

These sausages are divided into the highest, 1,2,3 grades.

The most common semi-smoked sausages are:

The highest grade: Armavir, Krakow, Poltava, Tallinn, hunting sausages, Ukrainian fried;

1st grade - Minsk, Odessa, pork, Ukrainian;

2nd grade - Semipalatinsk, lamb, Polish;

3rd grade - special, offal, prepared from the meat of the heads, lips, scars and fleshy offal.

1. 3 Technological processes for the production of semi-smoked sausages

The production process of each type of sausage products has its own characteristics. However, the operations of preparing raw materials for sausage production are common for most sausage products.

One of the first processes of preparation of raw materials is the process of cutting. Cutting is an operation for dismembering carcasses or half carcasses into smaller cuts.

Meat carcasses (half carcasses) are cut into cuts in accordance with standard schemes. With specialized cutting in sausage production, the entire carcass (half-carcass) is used to produce sausages.

The meat supplied for cutting, deboning and trimming must have a temperature in the thickness of the muscles at a depth of at least 6 cm from the surface:

Chilled and defrosted 1-4 °C;

Steam not lower than 35 °C;

Cooled no higher than 12 °C.

The next process of production of raw materials is deboning. This is the name of the process of separating muscle, fat and connective tissues from bones. Deboning is best done using a differentiated method, when each worker deboning a certain part of the carcass, however, at low-capacity enterprises, carcass deboning is used, when the entire carcass is processed by one worker.

Deboning is carried out on stationary and conveyor tables. At a number of enterprises, carcasses are deboned in a vertical position on overhead tracks.

Permissible content of fleshy tissues on the bones after deboning - up to 8%. To increase the yield of raw materials, additional deboning is carried out - the separation of pulpy tissues remaining on the bones after complete manual deboning. The most common are two methods of additional deboning of the bone: in saline solutions and pressing.

Additional deboning in brine is carried out in rotating apparatus for several hours.

As a result of the chemical action of the sodium chloride solution and mechanical friction and impacts of the bones against each other and against the internal elements of the apparatus, soluble proteins of muscle tissue pass into the solution. Connective tissue proteins swell, which helps to reduce the strength of the fleshy tissues and separate them from the bone with the formation of a meat suspension.

Additional deboning of bones by pressing is carried out using rotary or screw presses of continuous action and piston presses of periodic action.

After deboning, the trimming process follows. This is the process of separating from meat small bones remaining after deboning, tendons, cartilage, blood vessels and films, bruises and contamination. Thanks to the trimming, the nutritional value of meat increases.

The trimming is carried out manually with a special knife.

When trimming pork meat, the end tendons of the shank and shank, scapular cartilage, patella, etc. are removed.

When trimming meat trimmings (including cuttings of meat from tongues) and diaphragms, coarse connective and adipose tissues are exposed, impurities, lymph nodes and glands are removed. When trimming the cheeks, the lymph nodes and salivary glands are removed.

When trimming the meat of the heads, coarse connective tissue, salivary glands, lymph nodes are isolated, impurities are removed, and the remnants of the skin are removed from the meat of the heads.

When trimming meat, the following basic rules must be observed:

The meat is cut into individual muscles or their groups;

Fascia is separated parallel to the course of the muscle fibers;

Muscles are cut in the longitudinal direction into pieces weighing no more than 1 kg;

The veined piece of meat is placed with the connective tissue down and the trimming knife (moving away from you) separates the meat from the connective tissue;

You should not accumulate a large amount of deboned and trimmed meat on the tables in order to avoid a decrease in its quality.

Meat sorting is based on the division of trimmed meat into grades depending on the content of connective and adipose tissue in it.

Trimmed beef is divided into 3 grades:

1. top grade - pure muscle tissue of hams, shoulder blades and dorsal muscles (approximate yield 15-20%);

2. first grade - muscle tissue with a content of not more than 6% of connective tissue and fat from all parts of the carcass (output 40-50%);

3. second grade - muscle tissue from the chest, drumstick, shank, neck, flank, with a content of not more than 20% connective tissue and fat (yield 35-40%).

When trimming and sorting well-fed beef, fatty beef is isolated - muscle tissue with a content of adipose and connective tissues of not more than 35%.

Pork trimmed, depending on the fat content, is divided into low-fat, semi-fat and fatty. Lean pork contains no more than 10% adipose tissue (approximate yield 20-30%), bold pork - 30-50% adipose tissue (50-60% yield), fatty pork - more than 50% fat (10-30% yield). Lean and semi-fat pork meat is cut from hams, back loin and shoulder blades, fatty meat is cut from flank, rib and other parts.

Trimmed beef is the basis of minced meat for most sausages, and depending on its quality, sausages are divided into commercial grades.

Sausages of the highest grade, as a rule, are made from trimmed beef of the highest grade, sausages of the 1st grade - from trimmed beef of the 1st grade, sausages of the 2nd grade - from trimmed beef of the 2nd grade.

Only in the production of semi-smoked sausages of the highest grade, trimmed beef of the 1st grade is used, and sausages of the 1st and 2nd grades trimmed beef of the 2nd grade.

Low-fat pork is used mainly for smoked and boiled sausages of the highest grade, bold pork - for boiled sausages of the 1st and 2nd grades and semi-smoked.

Raw materials for the production of semi-smoked sausages are beef, pork, lamb in a cooled, chilled and thawed state, back and side fat, pork brisket with a mass fraction of muscle tissue of not more than 25%, raw mutton fat. For the production of certain types of semi-smoked sausages, by-products of categories 1 and 2, protein preparations (food caseinates, soy protein preparations) are used.

Preparation of raw materials. Frozen meat on the bone is pre-thawed. Chilled raw materials with a temperature in the thickness of the muscles of 0-4°C or defrosted with a temperature of at least 1°C are sent to the deboning. In the process of trimming, beef, lamb, pork are cut into pieces weighing up to 1 kg, pork back fat, side fat and brisket are cut into strips measuring 15 x 30 cm.

Fatty raw materials (fatty pork, raw fat, brisket and bacon) before grinding are cooled to 2 ± 2 ° C or frozen to -3 -1 ° C.

Preliminary grinding and salting of meat. Grinding meat before salting accelerates its maturation and the process of salt penetration into tissues, and also increases its water-holding capacity during heat treatment.

Meat for semi-smoked sausages is cut into pieces weighing up to 1 kg or ground on tops with a lattice hole diameter of 2-4 mm.

When salting, sodium nitrite is added to the meat in the amount of 7.5 g per 100 kg of raw materials in the form of a solution with a concentration not higher than 2.5%.

Salted meat is placed in containers and sent for holding at a temperature of 0-40C. The duration of exposure depends on the type of products produced and on the degree of meat grinding and can vary from 6 (in the production of boiled sausages) to 168 (in the production of raw smoked sausages) hours. During aging, salt is evenly distributed in the meat, it becomes sticky and moisture-intensive as a result of changes in proteins under the influence of salt.

Preparation of lard, fresh or salted, consists in removing the skin and cutting it into pieces of a certain shape and size, corresponding to each name of the sausages. The bacon is ground on bacon cutters after pre-cooling to -10 °C.

Glava 2 . Technology for the preparation of semi-smoked sausages at OOO MK Daursky

2.1 Cooking minced meat

Minced meat for semi-smoked sausages is made from coarsely ground raw materials.

Minced meat structure. Unlike homogeneous meat emulsions, minced meat of this type has a partially preserved cellular structure. Fat is crushed, but practically not dispersed. The amount of water in the system is limited to that found directly in the meat and this consequently ensures a relatively high solids content.

A characteristic external feature of minced meat of this type is the presence of structural elements of meat visually observed on the cut, as well as looseness, expressed to some extent, providing the necessary drying rate and the development of enzymatic processes (raw-smoked and boiled-smoked sausages).

Microstructural analysis shows that the raw minced sausages of coarse grinding consists of particles that are extremely heterogeneous in composition, size and shape. The solid phase is represented by hydrated protein micelles, fatty particles encapsulated by a protein shell, fragments of destroyed muscle fibers, fat cells, fragments and pieces of connective tissue, etc.

The continuous liquid phase, as in finely divided emulsions, is an aqueous solution of protein and low molecular weight organic and inorganic substances. The specificity of the formation of such a complex system is due to the modes of technological processing of raw materials.

The traditional technology for the production of semi-smoked sausages provides for primary grinding of raw materials on a top with a lattice hole diameter of 2-3 mm to 16-25 mm, cured in salting.

In some cases, you can salt the meat directly in pieces. At the end of the salting, the raw materials (meal and lumps) are subjected to secondary grinding on a top (grid diameter 2-3 mm) and sent to the mixer for mixing.

Minced meat is a mixture of components previously prepared in quantities corresponding to the recipe for a given type and variety of sausages.

Chopped, beef, lamb and lean pork are mixed in a mixer for 2-3 minutes with the addition of spices, garlic and sodium nitrite (if it was not added when salting the raw material). Then, half-fat pork chopped into pieces is added in small portions and mixed for another 2-3 minutes. Lastly, bacon, raw fat are added, gradually scattering them over the surface of the minced meat, and mixed for 2 minutes.

When using unsalted raw fat or bacon, salt is simultaneously added at the rate of 3% by weight of unsalted raw materials. Mixing is carried out until a homogeneous minced meat is obtained and pieces of brisket, raw fat, bacon and bold pork are evenly distributed in it. The total duration of mixing is 6-8 minutes.

The minced meat temperature should not exceed 12 °C. The time interval from the end of minced meat preparation to the start of shell filling should not exceed 6 hours.

Grinding: depending on the type of sausages, the degree of grinding of raw materials is different.

Fine grinding of meat is carried out in cutters. The structure and consistency of minced meat, as well as the yield of finished products, depend on the correct cuttering. During the processing of meat on a cutter, during the first 3-4 minutes, mechanical destruction of tissues occurs, the surface of meat pieces increases significantly, after which the proteins begin to swell, bind water and form a viscoplastic structure.

The optimal duration of cuttering is considered to be when such indicators as stickiness, water-binding capacity of minced meat, consistency and yield of finished sausages reach a maximum (on average, cuttering lasts 8-12 minutes). To exclude heating of raw materials during cutting, ice or cold water is added to the cutter.

When preparing minced meat, beef or lean pork is first loaded into the cutter, and phosphates are added at the same stage, which increase the water-binding capacity of the meat.

Minced meat and finished products of higher quality are obtained by grinding raw materials on vacuum cutters (VK-125, K-45KV., L23-FKV - 0.5).

Heterogeneous minced meat containing pieces of bacon or coarsely ground pieces of meat is made up in mixers.

When preparing minced meat, beef and lean pork are first loaded into the mixer, then, if necessary, cold water or ice, spices. Fatty pork and bacon are loaded last.

After adding the bacon, the minced meat is stirred for 2-3 minutes. The duration of mixing depends on the design of the mixer and the properties of minced meat. So, the minced meat of semi-smoked and smoked sausages is mixed for 6-10 minutes.

2.2 Molding

Syringe (filling the shell with minced meat) is carried out under pressure in special machines - syringes - mechanical, pneumatic, hydraulic, vacuum. The stuffing density of minced meat into the shell is regulated depending on the type of sausage products, the mass fraction of moisture in the minced meat and the type of shell. Smoked sausages are injected most densely, since the volume of loaves is greatly reduced during drying.

To seal, increase mechanical strength and brand mark, after injection, sausages are tied with twine according to the schemes available in the relevant standards. When producing loaves in artificial casings, on which the name and type of sausage are printed, cross dressings can be omitted.

After knitting the long loaves to remove the air that got into the minced meat during its processing, the shells are pierced in several places (striped) at the ends and along the long loaf with a special metal striping having 4 or 5 thin needles. Loaves in an artificial shell do not trim.

Sausage casings can be classified according to a number of properties. The classification is based on two parameters: the material from which the sausage casing is made, and the level of gas and vapor permeability. These factors are interrelated. Natural shells and artificial ones made from natural materials are characterized by a high level of permeability to water vapor and gases. Artificial casings can be permeable or impermeable.

Protein casings: the shelf life of products in it, subject to the temperature regime, is from 3 to 5 days. In terms of their properties, protein shells are closest to natural ones - they are permeable to smoke, do not lag behind the filler during maturation, but have a number of important differences.

These materials are more technologically advanced, do not require complicated stages of preparation, and have stable properties - diameter, strength.

Protein shells are more convenient in terms of design: color variations, printing are possible. Collagen shells are cheaper.

Cellulose and fibrous casings are highly permeable, which makes it possible to pack in them not only boiled sausages and sausages, but also boiled-smoked and semi-smoked, sausages, sausages. The product in them can be smoked, they are suitable for almost any type of sausage.

However, high permeability means at the same time that the product can dry out in the package and the paint applied to the film can penetrate into it.

At MK "Daursky" natural and artificial casings are used for semi-smoked sausages.

Before heat treatment, the precipitation process is carried out.

Draft is an exposure of sausages in a suspended state for a different time, depending on the type of product and the size of the loaves.

Tied loaves are hung on sticks and frames and subjected to precipitation for 2-4 hours at 4-8C with a relative humidity of 80-85%, after which they are sent to heat treatment.

Short-term draft is carried out in the manufacture of boiled and semi-smoked sausages, it lasts 2-4 hours at a room temperature not higher than 120 C. Long-term draft (5-7 days) is used in the production of raw smoked sausages, as well as semi-smoked (1 day) and boiled-smoked sausages made from frozen meat. A long draft is carried out in special chambers, where the relative humidity of the air is maintained at 85-90% and the temperature is 4-8 or 2-4 ° C, depending on the type of sausages and the cooking technology.

During sedimentation, the structure improves and the density of minced sausages increases as a result of stronger binding of the particles of the chopped part of the minced meat to each other, and as a result of a stronger binding of the chopped part of the minced meat to the unground part (pieces of bacon, brisket, fatty pork or raw horse fat).

The end of the sediment is determined by the degree of drying of the shell, tightly fitting the loaf, when pressed, the minced meat is not pressed. The stuffing becomes elastic, bright red.

2.3 Heat treatment

It is carried out in stationary roasting, cooking and smoking chambers or continuous thermal units with automatic temperature and relative humidity control. Smoke for roasting and smoking is obtained by burning hardwood sawdust (bark is removed from birch firewood) in smoke generators of various designs or by burning sawdust and firewood directly in the chambers under the product.

Roasting is a process of heat treatment and diffusion treatment of sausages with an air-smoke mixture, in which both the properties and the state of the sausage casing, surface and deep layers of minced meat noticeably change. As a result of roasting, the properties and state of the sausage casing and the surface layer of minced meat under the casing change.

When roasted, the surface of the loaves turns brownish-red with a golden hue, the product acquires a specific smell and taste of smoke substances.

Loaves after precipitation are fried at t 80-90 C for 60-90 minutes. The end of the roasting process is determined by the drying of the shell, the reddening of the surface of the loaves and the achievement of t in the center of the loaf of 40-50 C. The loaves of semi-smoked sausages are dried and fried in combined chambers at t 90-100 C, relative humidity 10-20% and the speed of movement of the smoke-air medium 2 m/s. For 15-20 min. Until the end of roasting, the humidity in the chamber is increased to 52% so that the shell does not wrinkle.

Cooking - heat treatment of the product in a humid heating environment under conditions that provide it with the required properties for a set time. A humid environment can be steam, steam-air, etc. It is used as one of the intermediate processes of technological processing of raw materials and as the final stage of production in order to bring products to a state of culinary readiness, which is characterized by a certain consistency, smell, taste and color of products.

After frying, the loaves are steam-boiled in steam chambers at a temperature of 75-85 °C until a temperature of 70-72 °C is reached in the center of the loaf. The duration of cooking (depending on the diameter of the loaf) is from 40 to 80 minutes.

Cooling - after heat treatment, a small part of the microflora remains in sausages, and if the temperature of the product is high enough (35-38 ° C), then microorganisms will begin to actively develop, which will cause damage to the product.

To create conditions unfavorable for the development of residual microflora, sausages are cooled to a temperature of 8-12 °C.

When cooling, it is necessary to take into account the fact that a decrease in the temperature of the product is accompanied by intensive evaporation of water, which reduces the yield of finished products.

Half-smoked sausages after cooking are cooled at a temperature not exceeding 20 ° C for 2-3 hours, and then the sausages are sent for smoking.

After smoking, the sausage is cooled in chambers to a temperature inside the loaf of 10-12 °C.

Smoking - processing of food products, mainly meat and fish, with smoke obtained from the combustion of wood (sawdust, shavings, wood chips and firewood) in order to give products special taste properties and increase their durability during subsequent storage.

The smoking process includes the following operations: obtaining smoke; preparation of products for smoking, processing of products for smoking (actual smoking), processing of products at the end of the actual smoking. Smoking semi-smoked sausages, depending on the equipment used, is carried out in two ways.

During heat treatment in stationary chambers, sausages after cooking are cooled for 2-3 hours at a temperature not exceeding 20 °C. Then the sausage is smoked in roasting or smoking chambers at a temperature of 35-50 ° C for 12-14 hours.

During heat treatment in combined chambers and continuous thermal units, smoking is carried out immediately after roasting, gradually reducing the temperature in the chamber from 90-100 ° C to 39-45 ° C for 6-8 hours, maintaining the relative humidity of the smoke-air environment within 60-65 % at a speed of its movement of 1 m/s.

Drying - sausages are dehydrated by convective drying. In this case, the supply of heat necessary for heating the product and removing water occurs as a result of heat exchange between the surface of the product and the drying agent (air). At the same time, water evaporated from the surface of the product is removed into the heat transfer medium.

During the initial drying period, the surface temperature of the product rises or falls to the wet bulb temperature. Only from this point on, the process of convective drying, if the temperature of the drying agent is constant, can be considered established.

The sausage is dried at a temperature of 10-12°C and a relative air humidity of 74-78% for 1-2 days until the product acquires an elastic consistency and mass fraction of moisture, regulated by regulatory documentation.

2.4 Nutritional value and chemical composition

The nutritional value of sausages is higher than the value of raw materials and most other meat products, which is explained by the fact that during the production of sausages, the least nutritionally valuable tissues are removed from raw materials.

The high nutritional value of sausages is also due to their high content of protein and extractives, low-melting pork fat. Adding milk, butter and eggs not only increases the nutritional value, but also significantly improves their taste.

Sausages, like other meat products, are mainly sources of protein, so their nutritional value should be determined by both the total protein content and the amount of complete proteins. The amount of fat should be within the limits at which the quality indicators of sausages (taste, texture) improve, since in excessively large quantities fat worsens the taste of the products and their digestibility. When compiling sausage recipes, the content of essential fatty polyunsaturated acids, macro- and microelements, vitamins and digestibility in the finished product should also be taken into account.

Semi-smoked sausages contain a lot of fat - 30-40% and are highly nutritious. They contain 35-60% moisture and 2.5-4.5% salt. Sausages intended for long-term transportation contain 4-9% less moisture than sausages made for local sale.

Premium sausages contain little moisture and can be stored for a long time.

Food is a source not only of energy, but also of plastic substances necessary for building and updating the protein structures of the body, as well as vitamins and mineral salts, without which normal metabolic processes are impossible. Introduced into the composition of sausages, vegetable proteins in combination with animals create biologically active amino acid complexes that ensure the physiological usefulness and high digestibility of amino acids in the process of intracellular synthesis.

Thus, sausage products should be produced with a given chemical composition in terms of protein, fat, moisture and other substances by selecting raw materials and optimal production technology.

During smoking, a reaction occurs between the functional groups of proteins and the individual components of the smoke. The interaction of smoke components with the constituent parts of meat is evidenced by the formation in the process of smoking of new substances that affect the taste and aroma of smoked meat products.

In addition to those volatile substances contained in smoke, ammonia, hydrogen sulfide and methylamine are released from sausages. In the process of smoking, phenols and aldehydes accumulate in meat products, which accumulate intensively in the first 24 hours and have antioxidant effects.

The influence of different types of firewood on the quality of smoked sausage is very high, both in terms of the accumulation of phenols, and in terms of smell and taste.

The presence of benzpyrene in the smoke, which contributes to the development of cancer, has led to the use of smoke preparations for smokeless smoking.

VNIIMP (All-Union Scientific Research Institute of the Meat Industry) developed smoke preparations VNIIMP and VNIIMP - 1, which are made from pure chemical compounds. The technology of using the drug is very simple, they are added to the cutter or mixer in a certain proportion, which facilitates the mechanization and automation of the heat treatment of sausages and contributes to the creation of mechanized production lines.

2.5 Quality assessment of semi-smoked sausages

At all stages of sausage production, control over compliance with technological regimes is carried out. Temperature control inside the block meat raw materials in carcasses and half carcasses is carried out by a semiconductor temperature meter.

The minced meat temperature in the cutter is measured by a thermal resistance with thermal indication. The number of revolutions of the cutter bowl and the duration of cuttering - with a stopwatch according to GOST 5072-79E or digital tachometers. Temperature control in the raw materials, injection shops, in the cages, drying of finished products is carried out by glass liquid (non-mercury), alcohol thermometers in accordance with GOST 28498-90 with a division scale from 0 to 100C.

The control of relative air humidity in the settling chamber, dryers, storage chambers for finished products should be carried out by psychrometers, aspiration hygrometers and metrological hygrographs.

In automatic heat chambers, temperature and humidity control is carried out by automatic potentiometers or electronic bridges, which must comply with the requirements set forth in GOST 22261-82, GOST 9999-79.

The speed of air movement in sedimentary, thermal chambers, dryers is measured by anemometers.

Weighing raw materials during salting and compiling spice formulations is carried out on general-purpose scales in accordance with GOST 23676-79, GOST 14004-68 or weight batchers in accordance with GOST 24619-81. The control dosing of a solution of sodium nitrite when salting raw materials or preparing minced meat is carried out according to its mass fraction in the finished product.

At the end of the technological process, the sausage is checked organoleptically, and those that do not meet the requirements of technical specifications are rejected. Raw-smoked sausages with production defects (with gray spots, voids, etc.) are sent for the production of cooked-smoked, semi-smoked sausages of the first grade in an amount of up to 3% by weight of raw materials, in excess of the recipe in accordance with the current regulatory and technical documentation. The rules for sampling and preparing them for testing, test methods, frequency of quality control are carried out with the requirements of technical specifications for these types of products.

Defects in sausages. The main types of spoilage of sausages include sour fermentation, mold, discoloration, rancidity, and putrefaction.

Often damage manifests itself in a complex way.

Acid fermentation is caused by microorganisms that decompose carbohydrates (micro- and streptococci, lactobacilli, microbes from the family of intestinal bacteria) with the formation of acids. This type of spoilage is usually noted in boiled and liver sausages with the presence of vegetable additives or liver tissue. In uncooked smoked sausages, this type of spoilage is noted when ripening is carried out quickly and intensively, as well as in the presence of a high sugar content in minced meat with the ripening of sausages at elevated temperatures. A specific sour smell is detected immediately after breaking or cutting sausages. Cooling and storage of sausages at elevated temperatures, insufficient cooling of finished products lead to the appearance of acidic fermentation.

If this type of damage is detected, the products are sent for technical purposes.

Molding of sausage products is caused by the development of various types of microscopic fungi of the genera Penicillium, Aspergilliis, Mucor, Cladosporium, etc. Some types of microscopic fungi can form mycotoxins. This type of spoilage of sausage products usually appears when product storage conditions are violated, especially when relative humidity and air temperature increase, air exchange rate decreases in rooms where sausages are stored, and storage periods are exceeded.

Molding of sausages and smoked meats usually starts from the surface and can penetrate into the deeper layers of the product. At the initial stages, the mold does not have a significant effect on the products, later the integrity of the sausage casing is violated and microscopic fungi infect the deeper layers with a change in the consistency, color and smell of sausages.

Products with signs of the initial stage of mold are recommended to be cleaned and washed with a 20% solution of table salt, after which it is necessary to fry and smoke at 80-100 ° C for 1-2 minutes. In the later stages of mold damage, a change in color, smell and taste of products occurs. In those cases when it is impossible to remove the areas affected by mold by stripping, or in case of diffuse damage, sausages are sent for technical purposes.

Isolation and crystallization of table salt on the surface of sausages may resemble a thin coating of mold. The presence of salt is not an obstacle to the sale of sausages on a common basis. The change in the color of sausages can occur for various reasons: microbiological or physico-chemical.

The green tint in sausages appears in the center or along the periphery of the loaf. The reason for such changes may be the increased content of microorganisms in the raw material and its insufficient heat treatment, as well as the impact of viridans, a. piantarum or hydrogen sulfide producing bacteria.

The green hue of minced meat can also occur due to insufficient curing of meat in salting and violation of processing modes, the use of meat from animals that have undergone stress.

The gray color of sausages can be found both on the surface and in the deep layers of the product. Storing sausages in conditions of high humidity can lead to the appearance of gray deposits due to the development of coccal forms of microorganisms, yeasts or molds. In those cases when, without violating the integrity of the loaves, it is possible to remove plaque by washing them with 20% brine or cleaning them without using liquid, the sausages are dried and sold on a common basis.

When this is not possible, the products are sent for processing or technical purposes, depending on the nature of the changes.

The gray color of sausage products in the section arises as a result of the influence of vital activity in raw materials and finished products of microorganisms that form oxidases, peroxidases or hydrogen sulfide, which convert azoxyhemochromogen into hematin, which has a gray color. The appearance of gray coloration of products also occurs when using meat with a tan, stale meat, fat with a large amount of peroxides, as well as with a lack of sodium nitrite; as a result of prolonged contact of raw materials with air after cutting, exposure of boiled sausages to light, lack of myoglobin in young meat, deviations in roasting regimes, use of meat from animals that were injected with antibiotics before slaughter, and from animals killed in a state of stress.

Sliming of sausage products is manifested in the form of a grayish-white coating. This defect is noted due to violation of the storage conditions of sausages with moisture condensation on their surface. A grayish-white coating of a specific musty odor, its thickness depends on the exposure of the product content to unfavorable conditions.

In microbiological studies, micrococci, streptococci, yeasts or gram-negative psychrophilic bacteria can be isolated from this plaque.

Rancidity of sausages and smoked meats is noted when using raw materials (lard) with signs of rancidity, as well as in cases of violation of the conditions and terms of storage of sausages. Products with such changes are not allowed to be sold.

The putrefactive decomposition of sausages is a complex process in which many types of microorganisms participate: cocci, proteolytic bacteria - hay bacillus, microbes of the genus Pseudomonas, etc. It is accompanied by the appearance of foul-smelling substances as a result of the decomposition of proteins, fats and carbohydrates. Putrefactive decomposition quickly captures the entire mass of products that contain a lot of moisture.

Its occurrence is facilitated by the violation of the modes of preparation of raw materials, mechanical and thermal processing, storage of finished products. When signs of putrefactive decomposition are found, as well as when insect larvae, rodent droppings are detected in the product, sausages are sent for technical purposes.

2.6 Packaging and labeling

Semi-smoked sausages are packed in wooden reusable boxes in accordance with GOST 11354, plank - in accordance with GOST 13361, polymer reusable, aluminum or in containers made of other materials permitted for use by the Ministry of Health of the Russian Federation, as well as in specialized containers or container equipment.

Containers for sausages must be clean, dry, without mold and foreign smell. Reusable containers must have a lid. For local sale, it is allowed to cover the container with wrapping paper in accordance with GOST 8273, parchment, sub-parchment.

It is allowed to pack sausages in repaired and sanitary-treated reusable wooden containers, which ensure the safety and quality of products.

The gross weight must not exceed 30 kg.

Half-smoked sausage of the same name is packed in each box or container.

Not whole loaves of semi-smoked sausages weighing at least 300 g are allowed for local sale.

At the same time, the cut ends of the loaf must be wrapped with a napkin made of cellophane in accordance with GOST 7730, parchment in accordance with GOST 1341, parchment in accordance with GOST 1760 or other materials approved for use by the USSR Ministry of Health, and tied with twine, thread or rubber band. The number of non-whole loaves should not exceed 5% of the batch.

Packages with packaged semi-smoked sausages of the same name, grade and date of manufacture are placed in corrugated cardboard boxes according to GOST 13513, reusable containers, specialized containers or container equipment. Net weight of packed sausages in boxes should not exceed 20 kg.

Packaged semi-smoked sausages are allowed to be packed in polymer reusable boxes with a gross weight of not more than 30 kg, as well as in specialized containers and equipment containers with a net weight of not more than 250 kg.

Semi-smoked sausages are produced vacuum-packed in transparent gas-tight films approved for use by the Ministry of Health of the Russian Federation; when serving cutting (slices) with a net weight of (50 ± 6), (100 ± 4), (150 ± 4), (200 ± 6), (250 ± 6) g or a net weight of 50 to 270 g; when cut in portions (whole piece) with a net weight of 200 to 500 g. Hunting sausages are produced by weight and packed in cardboard boxes with a net weight of not more than 1000 g.

Transport marking - in accordance with GOST 14192 with the application of the handling sign "Perishable cargo" and the tare weight.

It is allowed not to apply transport marking on reusable containers with products intended for local sale.

Marking characterizing the products is applied to one of the end sides of the shipping container with indelible odorless paint using a stamp, stencil or sticking a label indicating: the name of the manufacturer, his subordination and trademark; names and varieties of sausages; manufacturing dates; gross weight, containers; designations of this standard.

A similar label is placed in the container. In addition, each box, container or container-equipment includes a summary check indicating: net weight of sausage; the number and total cost of servings; date of manufacture.

In the absence of a total check, the above designations are indicated on the label.

Each cardboard box must have a colorfully designed label indicating: the name of the manufacturer, its trademark, the name and variety of sausages, nutritional and energy value, net weight, kg. and the cost of sausage with packaging, designations of this standard.

Each packaging unit of packaged semi-smoked sausages of serving cuts with a net weight of 50 to 270 g and portion cuts with a net weight of 200 to 500 g must have a label in the form of a colorful print on a film indicating: the name of the manufacturer, his subordination and trademark, name and varieties of sausage, nutritional and energy value, storage time and conditions, designations of this standard. In addition, each packaging unit is glued with a check from a heat-sensitive or self-adhesive receipt tape indicating: net weight and cost of a serving with packaging, date of manufacture.

The sale of semi-smoked sausages by weight in a retail network should be carried out if there is information on the nutritional and energy value per 100 g of the product (protein, fat, calorie content).

Label marking is as follows:

Name of the manufacturer;

Name and grade of sausage;

date of manufacture;

Net weight, gross weight;

Standard designation.

2.7 Transport and storage

Semi-smoked sausages are transported by all means of transport in covered vehicles in accordance with the rules for the carriage of goods in force for this type of transport.

In packaged form, they are transported according to the normative document for methods and means of packaging.

Means of securing cargo in transport packages in accordance with GOST 21650, with the main parameters and dimensions in accordance with GOST 24597.

Semi-smoked sausages are stored for up to 10 days. in a suspended state at a temperature not higher than 12? C and a relative humidity of 75--78%. In refrigerated rooms at a temperature not exceeding 6 ° C and a relative air humidity of 75--78%, half-smoked sausages packed in boxes can be stored for no more than 15 days, and at temperatures from minus 7 ° C to

9? C up to 3 months. In uncooled rooms at a temperature not exceeding 20 ° C, half-smoked sausages can be stored for up to 3 days. Semi-smoked sausages packed under vacuum in a polymer film are stored at a temperature of 5 to 8 ° C for serving cuts for no more than 10 days, for portion cuts - no more than 12 days; at a temperature of 12 to 15 ? C for serving cuts no more than 6 days, for portion cuts - no more than 8 days.

3 . Calculationraw materials

Meat processing production can be designed as part of a meat processing plant or as an independent enterprise meat processing plant. The initial data for the calculation of raw materials and finished products of the meat processing industry is the production capacity and the range of products. We accept a changeable capacity of 300 kg, the yield of finished products is 74% "Daur smoked" in accordance with the task.

We calculate the main and auxiliary raw materials according to the type of sausage based on the recipe and the yield of finished products.

The total mass of the main raw material Ms, kg/shift, is calculated by the formula:

where A is the shift production of sausages, kg;

and n is the yield of finished products, % by weight of unsalted raw materials.

Мc = 100*300/74= 405.4 kg/shift

The mass of raw materials by types and grades, salt, spices and other auxiliary materials Mn, kg, is determined by the formula:

where C is the consumption rate of raw materials, salt, spices and other materials, according to the recipe, kg.

M(beef)=100*50/74=67.57 kg

M(pork)=100*25/74=33.78 kg

M(brisket)=100*25/74=33.78 kg

M(salt)=100*3/74=4.05 kg

M (sodium nitirite) \u003d 100 * 0.0075 / 74 \u003d 0.01 kg

M (granulated sugar) \u003d 100 * 0.135 / 74 \u003d 0.18 kg

M (ground black pepper) \u003d 100 * 0.09 / 74 \u003d 1.27 kg

M (ground allspice) \u003d 100 * 0.075 / 74 \u003d 0.1 kg

M(fresh garlic)=100*0.2/74=0.27 kg

Recipe for semi-smoked sausage "Daurskaya smoked"

|

Ingredient name |

Quantity in the recipe, kg |

|

|

Beef 1st grade |

||

|

Pork bold |

||

|

pork belly |

||

|

Food salt |

||

|

sodium nitrite |

||

|

fresh garlic |

||

|

Ground allspice |

||

|

Ground black pepper |

Conclusion

In this thesis, I examined the production process of semi-smoked sausages. Semi-smoked sausages have a higher shelf life compared to boiled sausages, as they contain less moisture, more salt and fat and have been smoked.

The range of sausages is huge. All sausage products must comply with the requirements of the standard, be produced according to the technological instructions for the production of sausage products in compliance with the rules for veterinary inspection of slaughter animals and veterinary and sanitary examination of meat and meat products, sanitary rules for meat industry enterprises, instructions for sanitizing process equipment and production facilities at meat industry enterprises.

According to microbiological indicators, sausages must comply with sanitary and epidemiological rules and regulations. The content of toxic elements (lead, arsenic, cadmium, mercury), pesticides, nitrosamines, antibiotics, radionuclides in sausages should not exceed the permissible levels established by sanitary and epidemiological rules and regulations.

...Similar Documents

The recipe for semi-smoked sausages made from pre-salted beef and pork meat, brisket, bacon. Description of the technological process of salting raw materials, processing by-products and preparing minced meat. Thermal processing and storage of sausages.

practice report, added 11/01/2011

Technology for the production of boiled-smoked, semi-smoked and raw-smoked sausages. Requirements for the quality of smoked sausages. Packing, marking, storage and transportation of sausages. Changing sausages during production and storage.

term paper, added 07/01/2013

History and perspective directions of development of sausage production. Commodity characteristics of semi-smoked sausages: classification, nutritional value, chemical composition, raw materials; technological scheme of production, quality examination; market research.

term paper, added 02/16/2011

Organizational and technological characteristics of the enterprise LLC "Ansei VMK". Production technology of semi-smoked sausages. Organoleptic assessment of the quality of sausages prepared according to traditional technology and using smoke flavoring.

thesis, added 01/11/2012

Requirements for the main raw materials and auxiliary materials in the production of semi-smoked sausages. Organoleptic, physical and chemical quality indicators. Organization of technochemical, microbiological and sanitary-hygienic control.

term paper, added 06/01/2014

Characteristics of raw materials, auxiliary food materials. Selection and calculation of technological equipment. Technochemical and microbiological control of the production of semi-smoked sausages "Krakowska" and "Poltavska" at the enterprise MUP "Uyar meat-packing plant".

thesis, added 01.10.2013

Production technology of semi-smoked sausages. Deboning, grinding and salting of meat, molding of sausages. Use of new production technologies. Improving equipment performance. Composition, size and structure of fixed assets.

term paper, added 05/13/2013

Indicators of the energy value of boiled, semi-smoked and raw smoked sausages. The use of fresh and chilled meat as a raw material. Full cycle of production of sausages. Methods for determining the quality of boiled sausages, their storage conditions.

presentation, added 12/14/2011

Features of the chemical composition, nutritional and biological value of boiled sausages. Factors that form and maintain the quality of boiled sausage. Characteristics of auxiliary raw materials used in the production of sausages. Defects in sausages.

term paper, added 10/21/2013

Technological scheme for the production of smoked sausages. Preparation of raw materials, its ambassador, preparation of minced meat. Filling shells with minced meat, sediment, smoking. Packaging, labeling and storage. The use of starter cultures for the production of smoked sausages.

The technological process for the production of semi-smoked sausages begins with the preparation of the main raw materials and auxiliary materials. Preparation of the main raw materials includes defrosting frozen meat, offal, cutting carcasses (half carcasses, quarters), deboning cuts, trimming and sorting meat and offal, hydration of protein preparations, preparation of protein stabilizer and protein-fat emulsions.

When preparing auxiliary materials, bulk products are sieved, the necessary compositions of spices are compiled, solutions of individual substances are prepared, certain operations for each type of casings (sorting, soaking, calibrating, washing, cutting into segments, applying staples, applying printed symbols, etc.) .

Frozen meat and offal sent for defrosting must meet the requirements of current standards.

They are pre-examined by a veterinarian in order to determine the presentation and further use.

Meat in carcasses, half carcasses and quarters is thawed on overhead tracks in special chambers designed for defrosting. Freezing chambers are recommended to be placed outside the refrigerator circuit, in close proximity to the meat cutting, deboning and trimming rooms.

Before loading frozen meat in the defrosting chambers, a temperature and humidity regime is created.